Pickering Laboratories - Analysis of Mycotoxins in Hemp and Hemp- Containing Edible Products

Pickering Laboratories developed an easy and sensitive method to analyze aflatoxins B1, B2, G1, G2, and ochratoxin A in hemp and hemp-containing edible products. Mycotoxins are isolated using immunoaffinity clean-up columns and analyzed with fluorescence detection. To increase sensitivity of aflatoxins B1 and G1, an in-line photochemical reactor (UVETM) is installed before the detector. This method utilizes standard HPLC equipment and allows laboratories to easily determine these mycotoxins at low ppb levels.

Method

Isolation of aflatoxins B1, B2, G1, G2, and ochratoxin A

Blend 1 g of finely ground sample with extraction solution (10 mL of methanol/water 80:20) using a handheld homogenizer. Centrifuge for 10 min. Mix 2 mL of the extract with 10 mL of PBS buffer (containing 2% Tween 20). Clean the extracts using AflaOchra HPLC immunoaffinity column (Vicam).

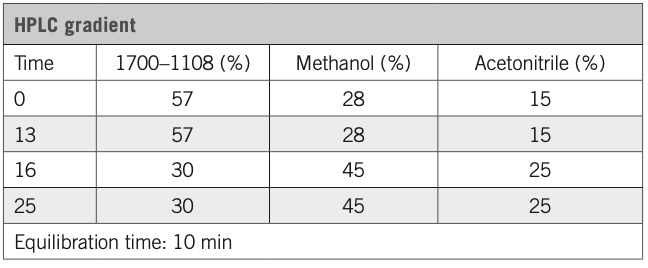

Analytical Conditions

Analytical Column: MycotoxTM (Pickering), C18, 4.6 × 250 mm

HPLC eluent: sodium phosphate buffer (Cat #1700–1108), methanol, acetonitrile

Flow rate: 1 mL/min

Post-column photochemical reactor: UVE (Cat # 10519 (240V), Cat # 10742 (120 V) FLD: Excitation 36 nm, Emission 430 nm for Aflatoxins Excitation 333 nm, Emission 477 nm for Ochratoxin A.

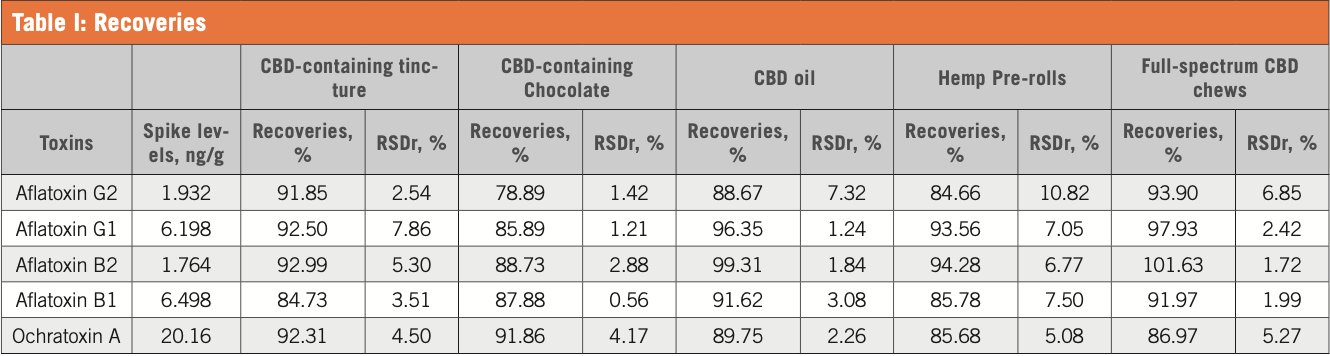

Calibration

The 5-point calibration curves were built in the ranges of 0.325– 3.25 ppb for B1, 0.088–0.882 ppb for B2, 0.310–3.099 ppb for G1, 0.099–0.996 ppb for G2, and 1–10 ppb for ochratoxin A. Correlation coefficient was R2 >0.999 for all toxins.

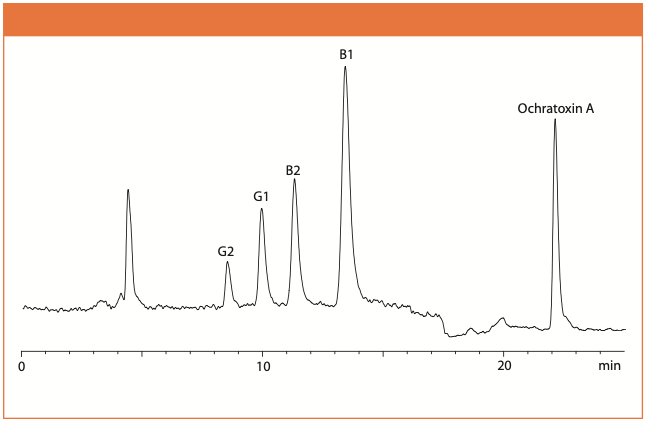

Figure 1: Chromatogram of hemp pre-roll spiked with 6.5 ng/g of aflatoxin B1; 1.8 ng/g of aflatoxin B2; 6.1 ng/g of aflatoxin G1; 1.9 ng/g of aflatoxins G2; and 20.1 ng/g of ochratoxin A.

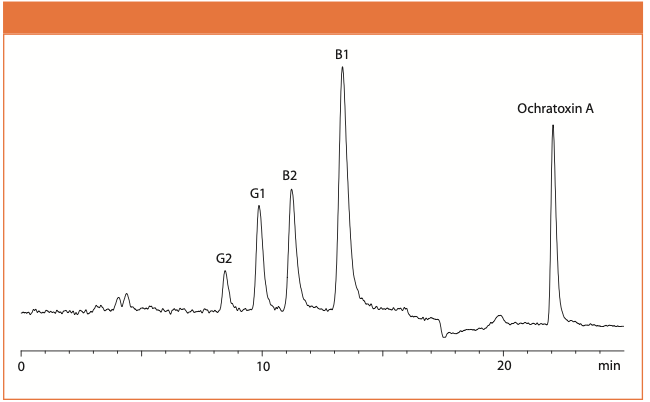

Figure 2: Chromatogram of hemp-containing chocolate spiked with 6.5 ng/g of aflatoxin B1; 1.8 ng/g of aflatoxin B2; 6.1 ng/g of aflatoxin G1; 1.9 ng/g of aflatoxins G2; and 20.1 ng/g of ochratoxin A.

Pickering Laboratories

1280 Speca Park Way, Mountain View, CA 04043

tel: (800) 654-3330, (650) 694-6700

Website: www.pickeringlabs.com

Automated Sample Preparation (ISO 20122) for MOSH/MOAH in Seasoning Oils

May 6th 2025This work presents an Automated Sample Preparation procedure for MOSH/MOAH analysis of Seasoning Oils. We compare results from a manual epoxidation procedure compliant with DIN 16995 with results based on fully automated sample preparation (epoxidation and saponification) compliant with ISO 20122. In both cases, online clean-up via activated aluminum oxide (AlOx) are used to remove interfering n-alkanes from the MOSH fraction during the HPLC run. Automated data evaluation using a dedicated software (GERSTEL ChroMOH) is presented.

Free Poster: NDSRI Risk Assessment and Trace-Level Analysis of N-Nitrosamines

April 25th 2025With increasing concern over genotoxic nitrosamine contaminants, regulatory bodies like the FDA and EMA have introduced strict guidelines following several high-profile drug recalls. This poster showcases a case study where LGC and Waters developed a UPLC/MS/MS method for quantifying trace levels of N-nitroso-sertraline in sertraline using Waters mass spectrometry and LGC reference standards.

New TRC Facility Accelerates Innovation and Delivery

April 25th 2025We’ve expanded our capabilities with a state-of-the-art, 200,000 sq ft TRC facility in Toronto, completed in 2024 and staffed by over 100 PhD- and MSc-level scientists. This investment enables the development of more innovative compounds, a broader catalogue and custom offering, and streamlined operations for faster delivery. • Our extensive range of over 100,000 high-quality research chemicals—including APIs, metabolites, and impurities in both native and stable isotope-labelled forms—provides essential tools for uncovering molecular disease mechanisms and exploring new opportunities for therapeutic intervention.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)