Advances in Solid-Phase Extraction to Improve the Analysis of Per- and Poly-fluorinated Alkyl Substances

This article explores the role of SPE sorbents for analyte recovery rates and method accuracy to develop clean samples for analysis and to reach lower limits of detection.

ONYXprj/stock.adobe.com

As a result of the unique nature of per- and polyfluorinated alkyl substances (PFAS) and their emerging health concerns, testing methods have evolved to be more efficient and solid-phase extraction (SPE) has become an essential clean-up step in the PFAS workflow. Since the original promulgation of regulated methods, new compounds have been identified and the investigation of more diverse matrices have made it increasingly more difficult to extract and analyze PFAS. This article explores the role of SPE sorbents for analyte recovery rates and method accuracy to develop clean samples for analysis and to reach lower limits of detection.

Per- and polyfluorinated alkyl substances (PFAS) are potentially harmful compounds that have been introduced to environmental, food, and biological samples as a consequence of their widespread commercial use over the past 50 years. Analysis of these compounds has been historically difficult because of their overwhelming prevalence, multiplicity of chemical analogues, and closely related molecular structures. Consequently, the need for more efficient analysis and extraction of PFAS has significantly grown, with the need to adopt methods for diverse sample types as well as to account for the proliferation of PFAS structure.

As newer methods are adopted there has been a strong focus on sample preparation method that act as the vital part of the extraction and clean‑up portion of the PFAS workflow. The original United States Environmental Protection Agency (EPA) 537 Methods were limited to a list of 14 analytes and the sample matrix was restricted to drinking water. This simplicity made the methods relatively straightforward with regards to solid-phase extraction (SPE) and LC–MS/MS analysis. However, with the expanding list of PFAS compounds and matrix diversity, the methodology has evolved and SPE sorbent chemistry has become much more important for achieving the accurate analysis of PFAS in environmental samples.

The Basics of SPE

SPE is one of the most versatile modes of sample preparation, employing a unique combination of sorbent chemistry and elution conditions to bind, clean‑up, and release analytes in simple, sequential steps. When done effectively, SPE can achieve three essential goals in an extraction: clean‑up the matrix, concentrate the sample, and provide a solvent-switching mechanism to a more compatible mobile phase that is more compatible with mass spectrometry (MS) analysis. Consequently, many laboratories choose SPE over less complicated, but less versatile methods because even though the method development process may be longer, SPE results in a cleaner extract that is easier to process by LC–MS/MS.

There are diverse sorbent options available for SPE, both silica-based and polymer-based, so one first needs to understand why certain SPE sorbents are selected for certain PFAS extractions. To begin the sorbent selection process, the characteristics of the sample matrix first need to be determined. For PFAS testing this could be drinking water, wastewater, soil, sediment, food samples, or even tissue, or whole blood. The next step in the SPE sorbent selection is to consider the analytes of interest, in this case PFAS. Once the sample matrix and target analytes are considered, this will determine the SPE approach that is the best fit for the analysis.

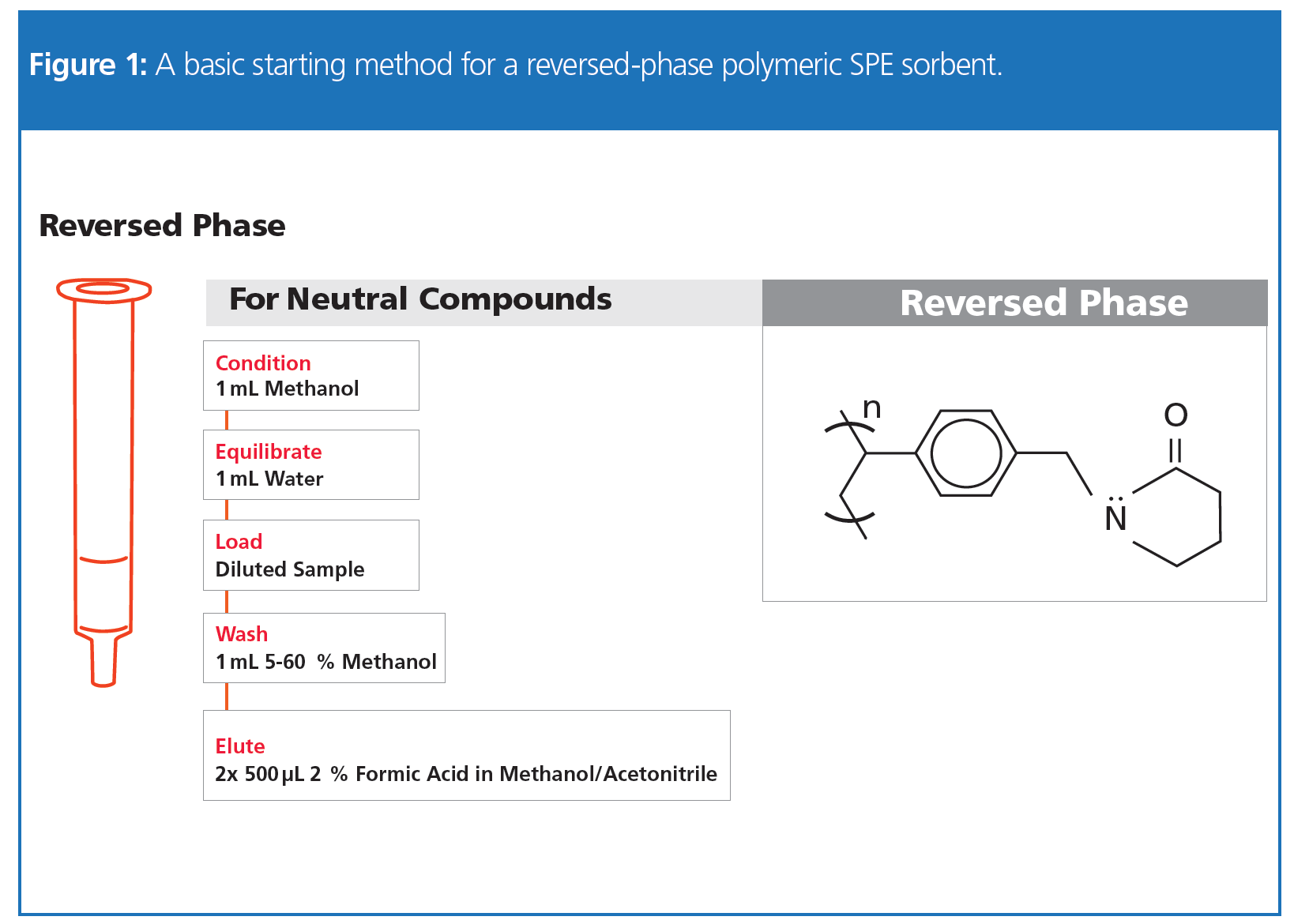

The common extraction/elution steps for a reversed‑phase sorbent method are presented in Figure 1. While seemingly straightforward, many issues can arise in SPE from both sorbent selection and wash/elute solvent selection. Considering that PFAS consist of both long and shorter chain compounds of varying hydrophobicity, care must be taken in the wash and elution steps to obtain a balance between ultimate sample cleanliness and analyte retention on the sorbent. Too strong a wash will result in low analyte recovery, but too weak a wash will result in insufficient sample clean‑up, potentially impacting the MS analysis. Since the regulated methods present a final, optimized set of conditions and do not discuss the SPE optimization process, the reader must rely on method development applications or white papers for more detailed treatment of the process, which can be found at vendor or publication websites.

PFAS from Drinking Water

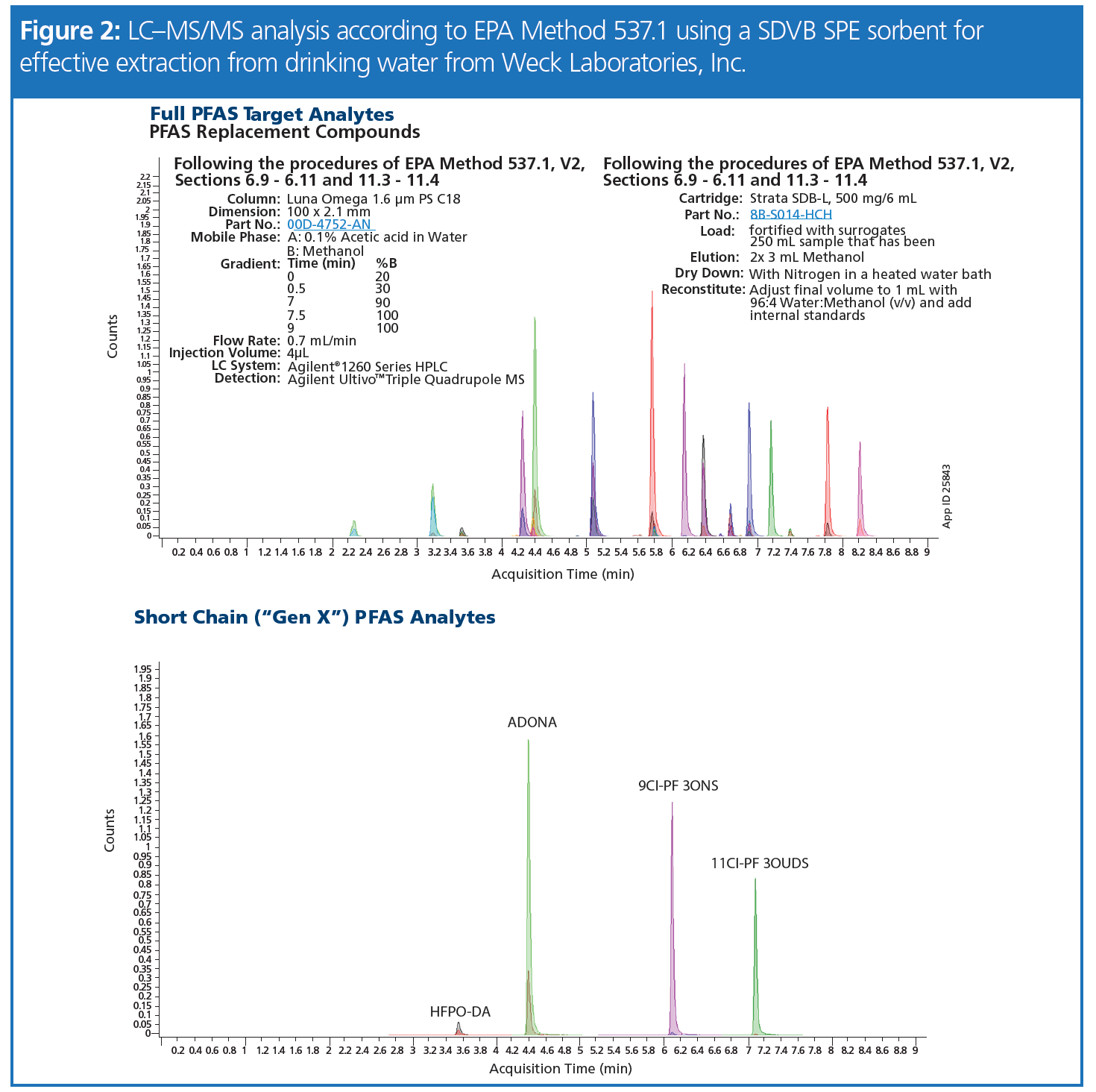

Since sorbent selection for SPE is derived from the combination of analytes and the sample matrix, the official EPA Methods communicate specific sorbent types based on the specific analyte list. EPA developed their first official PFAS Method (EPA Method 537) (1) specifically for drinking water to support the third Unregulated Contaminant Monitoring Rule (UCMR 3) (2). It consisted of 14 PFAS compounds with a focus on perfluorooctanesulfonic acid (PFOS) and perfluorooctanoic acid (PFOA) which had the highest historical usage. The original EPA 537 analytes are also included in the EPA 537.1 update along with four additional shorter-chain PFAS compounds (the so-called Gen X compounds) that had been subsequently introduced into manufacturing and now require analysis. Since all the compounds in the list hold the generally similar hydrophobic analyte characteristics of long chain alkyl substances, Method 537.1 continued to recommend a polystyrene‑divinylbenzene (PS‑DVB) for the extraction step. PS‑DVB is a polymeric sorbent that offers hydrophobic selectivity for reversed-phase application and works well to extract long chain and the four additional shorter chain PFAS with high recovery. Figure 2 displays analytical results for the PS-DVB SPE method used in EPA Method 537.1 showing how both the long chain and shorter chains PFAS are adequately resolved by LC–MS/MS analysis with excellent retention.

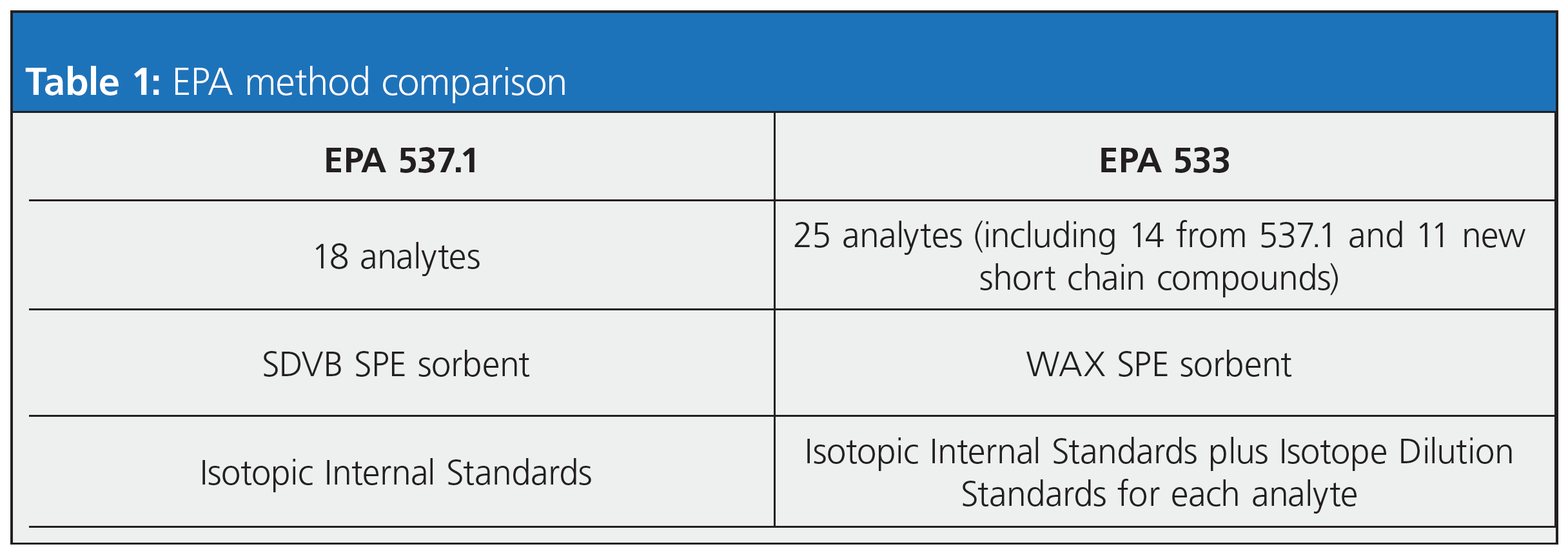

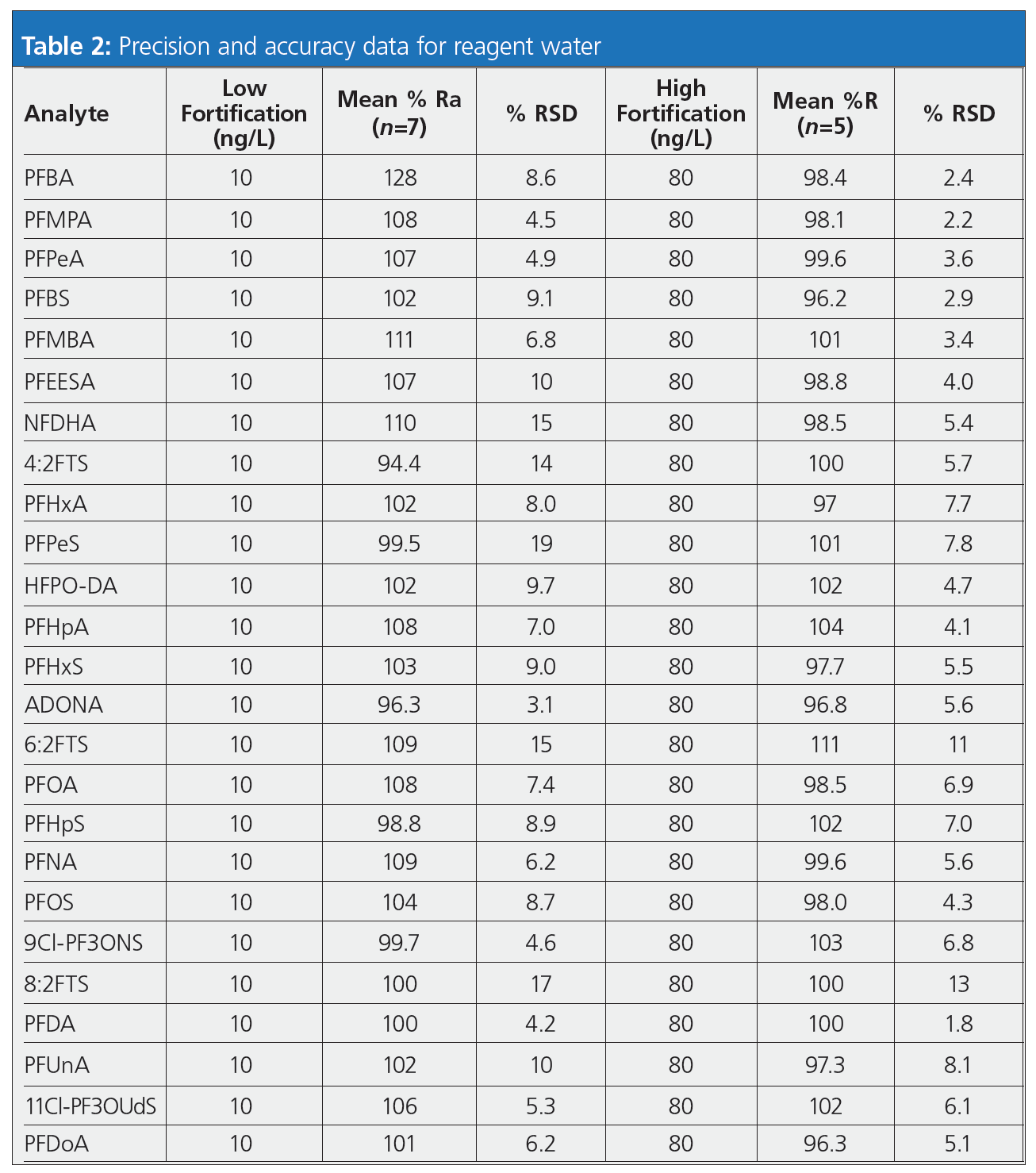

A more recently-released method (EPA Method 533) was developed to complement the original method for PFAS analysis with an expanded list of 25 analytes with a greater diversity of chemical characteristics which offers a more complete solution for both the long chain and shorter chain PFAS compounds. However, the originally recommended PS‑DVB SPE sorbent may result in low analyte recoveries because some newly added compounds, such as pentafluorobenzoic acid (PFBA) and perfluoropentanoic acid (PFPeA), are too polar to be retained on the reversed‑phase SPE sorbent. For the 533 analyte list, a polymeric weak anion-exchange (WAX) sorbent was stipulated, having affinity for both the original, hydrophobic analytes and the new more polar/acidic PFAS analytes which are retained by an anion-exchange mechanism. In Table 1, a basic comparison of the two EPA Methods is presented. Table 2 presents analytical data for Method 533 showing high precision and accuracy for all 25 analytes, including PFBA and PFPeA.

PFAS from Biota

Complex sample matrices such as oils, sediments, treatment sludges, and biota (fish, benthos, etc.) are gaining greater attention as scientists seek to better understand the transport and fate of PFAS in the environment. Per the US Department of Defense (DOD) guidelines (DOD QSM 5.1/5.3), which outline testing of PFAS from non-drinking water sources, it states that weak anion-exchange (WAX) SPE sorbent in combination with graphitized carbon black (GCB) material is specified for added cleanliness. Traditionally there have been two ways to perform this procedure, both of which are time consuming and sometimes yield inaccurate results owing to their complex SPE processing procedures. One method employs a single SPE cartridge to extract the analytes followed by another SPE cartridge filled with GCB material to remove additional contaminates from these especially dirty matrices. A second method uses SPE cartridge sorption and the SPE eluate followed by GCB treatment in a dispersive mode (dSPE). For both approaches, significant time is required for the clean‑up and the multiple steps can present an opportunity of analyte loss and imprecision.

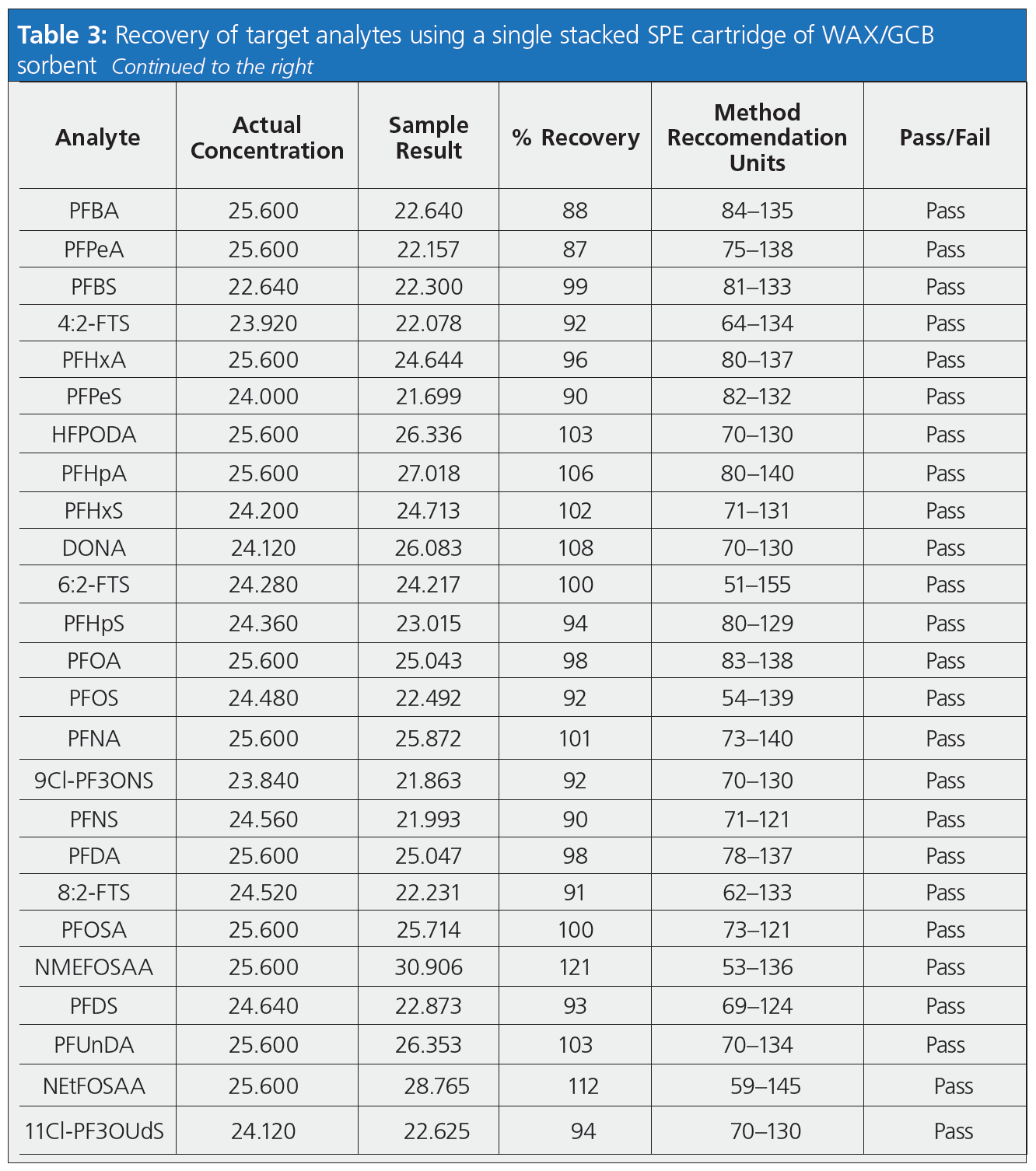

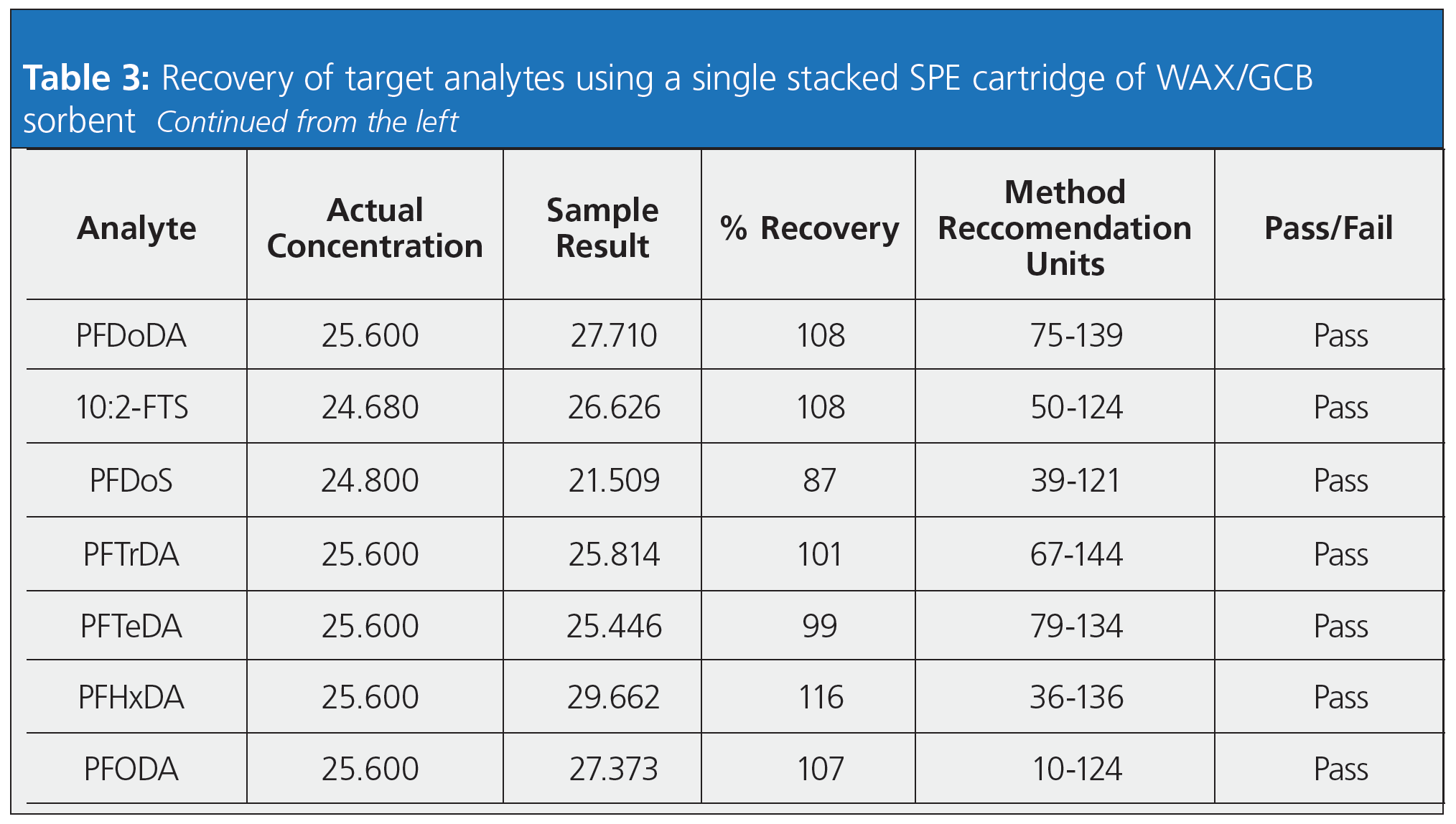

However, a new technology was recently released, that offers improved precision and accuracy by combining both SPE sorbents into a single tube. By combining both WAX and GCB sorbents into a single tube in a stacked manner, waste and time can be reduced while also improving accuracy. In addition, this single tube method is more economical owing to more rapid sample processing and reduced material cost (for example, one tube instead of two).

Table 3 presents data for the stacked cartridge solution. These data demonstrate acceptable method performance and data acceptability of all 32 analytes within method recovery limits. With an average analyte recovery of 98.8% and mean recovery of 99.0%, this demonstrates that the stacked SPE cartridge is “fit for purpose” in the performance DOD QSM 5.1/5.3.

PFAS from Food and Biological Matrices

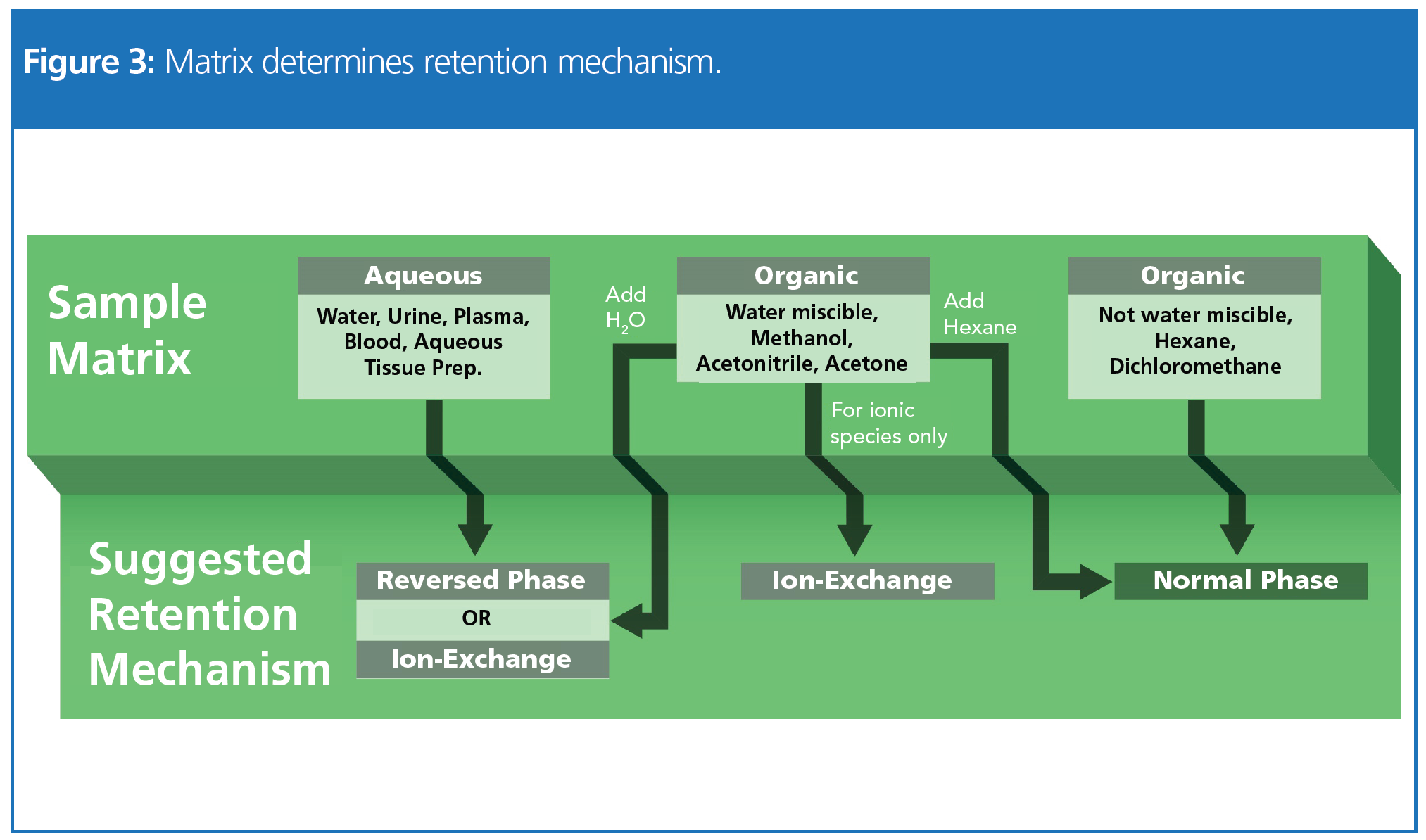

In addition to their presence in traditional environmental samples, PFAS are also prevalent in food products due to environmental impacts, thereby heightening concerns about human exposure and health effects. SPE sorbent selection is further complicated by this additional increase in matric diversity and complexity. However, Figure 3 displays a good starting point for evaluating the types of retention mechanisms that could be used for the extraction step. In this case, the sample matrix is extremely important to determine the optimum SPE retention mechanism. From there, specific SPE phases would be selected based on the PFAS analytes of interest. Most vendors offer additional tools to help determine the starting SPE sorbent and recommended protocol to begin with. In particular, the QuEChERS clean‑up procedure has been shown to be applicable for fatty food matrices (milk, cheese, fish, and so on) and for biota.

Conclusion

The process of defining PFAS extraction and purification conditions may seem extremely complex owing to the multiplicity of PFAS and their presence in diverse matrices. However, we have shown that breaking down specific methods according to the chemical characteristics of the target analyte list and the nature of the sample matrix can be very useful in defining optimal SPE sorbent selection and operating conditions. This then serves as the starting point to define the overall PFAS workflow. Good method accuracy and precision start with effective sample preparation, and SPE has been shown to provide a reliable foundation for PFAS method performance. As new SPE technologies are developed further, gains in analytical method performance can be expected, as well as commensurate gains in sample throughput and laboratory economics.

References

- J.A. Shoemaker, P. Grimmett, and B. Boutin, Determination of Selected Perfluorinated Alkyl Acids in Drinking Water by Solid Phase Extraction and Liquid Chromatography/Tandem Mass Spectrometry (LC/MS/MS) (U.S. Environmental Protection Agency, Washington, D.C., 2008).

- Contaminant Candidate List 3 (CCL 3) https://www.epa.gov/ccl/contaminant-candidate-list-3-ccl-3

- J. Shoemaker and D. Tettenhorst. Method 537.1: Determination of Selected Per- and Polyfluorinated Alkyl Substances in Drinking Water by Solid Phase Extraction and Liquid Chromatography/Tandem Mass Spectrometry (LC/MS/MS) (U.S. Environmental Protection Agency, Office of Research and Development, National Center for Environmental Assessment, Washington, D.C., 2018).

- https://denix.osd.mil/edqw/documents/

- D. Kennedy, S. Lodge, and A. Pierri, https://phenomenex.blob.core.windows.net/documents/e4265f51-d6db-42ac-9ee6-d8fad055b844.pdf, accessed on Sep. 14, 2020.

- A. Patterson, C. Neslund, R. Brown, S. Lodge, D. Kennedy, and B. Marshall, https://phenomenex.blob.core.windows.net/documents/ba582f2f-4927-4408-aace-4ecfff1a51c2.pdf, accessed on Sep. 14, 2020.

- A. Pierri and S. Lomas, https://phenomenex.blob.core.windows.net/documents/234361ad-5022-4cad-bb0a-5514059a1ba5.pdf, accessed on Sep. 14, 2020.

- S. Estil, E. Nelson, and S. Krepich, https://phenomenex.blob.core.windows.net/documents/2c9677ab-4ca8-450e-a134-6de2fc54a92a.pdf, accessed on Sep. 14, 2020.

- https://www.epa.gov/pfas/epa-pfas-drinking-water-laboratory-methods, accessed on Sep. 14, 2020.

- https://www.epa.gov/ground-water-and-drinking-water/drinking-water-health-advisories-pfoa-and-pfos, accessed on Sep. 14, 2020.

Jenny Cybulski graduated from Vanguard University of Southern California (California, USA) with a B.S. in biology and a minor in chemistry. She now works as a Product Marketing Manager for sample preparation products at Phenomenex, Inc. located in Torrance, California, USA.

E-mail: jennycy@phenomenex.com

Website: www.phenomenex.com

New Method Explored for the Detection of CECs in Crops Irrigated with Contaminated Water

April 30th 2025This new study presents a validated QuEChERS–LC-MS/MS method for detecting eight persistent, mobile, and toxic substances in escarole, tomatoes, and tomato leaves irrigated with contaminated water.

University of Tasmania Researchers Explore Haloacetic Acid Determiniation in Water with capLC–MS

April 29th 2025Haloacetic acid detection has become important when analyzing drinking and swimming pool water. University of Tasmania researchers have begun applying capillary liquid chromatography as a means of detecting these substances.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)