2008 Method Validation Survey

LCGC North America

To obtain a better understanding of the challenges faced during method development and validation, the authors - in cooperation with LCGC - conducted a survey earlier this year. This column summarizes the results.

High performance liquid chromatography (HPLC) method development and validation both present significant challenges in the chromatography laboratory in terms of time and resources, and there are many different approaches to answering them. With these challenges in mind, the editors of "Validation Viewpoint," in cooperation with LCGC North America, conducted a survey earlier this year (January 8–21, 2008) to better understand and prioritize the issues faced. Questions were posed on a variety of method development and validation issues to examine different approaches, identify areas of concern, and gauge respondents' ability to comply with current regulations and plan for the future. While results from this survey will be used to help guide content for future "Validation Viewpoint" columns, this column summarizes the results of this survey and offers comments where appropriate.

Michael E. Swartz

Demographics

Over 600 people responded to the survey; it was a very educated group split almost exactly evenly between the Doctoral, Master's, and Bachelor's levels. A high level of experience also was quite evident, as more than half of the respondents had over 10 years of experience. Age was not too much of a factor — method validation chores were carried out almost equally from generation X'ers to baby boomers. It is still a male-dominated environment, however, as 67.7% of the respondents fall into the Y-chromosome category. Respondents also were distributed evenly among small to medium (fewer than 50 employees, 14%; 50–1000 employees, 43.7%) and larger (>1000, 42.2%) organizations.

Ira S. Krull

People validating methods for synthetic drugs accounted for 31.8% of the responses, while biotherapeutics (for example, proteins and peptides) accounted for 12% of the responses, and 18.6% validate methods for both. The survey results suggest that there are still far more firms involved in synthetic, small molecule drugs than biotherapeutics, but that this number is growing.

At last, a little geography lesson: It might not come as a surprise that the majority of respondents ply their trade in the Northeast (Massachusetts, Connecticut, New York, New Jersey, Pennsylvania, Vermont, New Hampshire, Rhode Island, and Maine: 29.9%), followed by the Midwest (26.7%), Southeast (16.5%), Southwest (16.5%), outside the U.S. (7.4%), and the Northwest (3.0%).

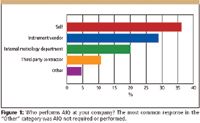

Setting the Stage — AIQ

Analytical instrument qualification (AIQ) must be performed for any instrument used to validate methods in a regulated environment. AIQ can be performed by the user, an internal company metrology department, the instrument vendor, or a third-party contractor. Although some respondents indicated using a combination of these resources to perform AIQ, when asked who performs this service at their company, the results in Figure 1 were obtained. Depending upon your vantage point, these numbers indicate either an untapped potential market for instrument vendors and third-party suppliers, or a desire on the part of regulated companies to exercise more control over the process or to save money. Given the time required to perform AIQ, the limited resources in many companies today, the proliferation of maintenance contracts and service agreements, and a better return on investment for these services, the frequency of AIQ being performed by instrument vendors and third-party suppliers could soon increase.

Figure 1

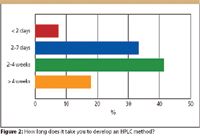

The Clock is Running

The fact that HPLC method development takes a significant amount of time and resources is not surprising. While a small percentage (7.4%) claimed they could develop a method in as little as two days, Figure 2 illustrates the fact that for many, it takes significantly longer, and respondents were near unanimous in stating that reducing the amount of time was either important (36.6%), very important (37.6%) or extremely important (19.1%). Drawing on experience, relying on the literature, automation, column screening, efficient experimental design, reducing HPLC run times using technology like ultrahigh-pressure LC (UHPLC), and using modeling software were some of the approaches reported to reduce method development time.

Figure 2

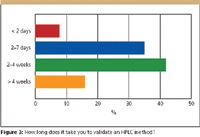

Method validation also takes a significant amount of time, and the results of this survey certainly bear this fact out. Time was cited as the most significant method validation challenge faced today by over a 5:1 ratio over the next factor cited. From acquiring the data, to the analysis, compilation, and reporting of results, a significant portion of the population spent a month or more on this task, and not surprisingly, over 90% say that reducing the amount of time spent on HPLC method validation is important (35%), very important (37.5%), or extremely important (18.3%). Figure 3 breaks down the overall amount of time respondents take to fully validate a method. Careful planning and organization, automation, reducing HPLC run times using technology like UHPLC, and adding resources were among the most common approaches cited to decrease the amount of time spent validating HPLC methods.

Figure 3

Software use also was cited commonly as a time saver. Excel is still the most common software used, by 49.5% of the respondents. It is readily available, inexpensive, and easy to use, in spite of its 21 CFR Part 11 electronic records limitations. Software incorporated into the chromatography data system (CDS) was used 31.7% of the time, and 14.1% use third party statistical software such as Minitab and JMP. Many used more than one approach; the most common being the CDS followed by third-party statistical software.

Robustness testing takes up the majority of HPLC method validation time, and 68.4% responded that they perform robustness testing as a part of method validation. In the rankings, robustness was followed by, in order, specificity, accuracy, limit of quantitation, linearity and range, precision, and limit of detection. However, when asked to rank the importance, accuracy was cited by the respondents as the most important part of method validation, followed by, in order, precision, specificity, robustness, linearity, and quantitation and detection limits.

Current HPLC Method Validation Challenges, and a Look to the Future

In addition to reducing time, several other HPLC method validation challenges were listed. The types of methods that seem to give people the most difficulty are methods validated for the analysis of degradation products and impurities. Robustness studies, problems with matrix effects, and specificity issues also were commonly reported. Other issues raised included precision, accuracy, sensitivity, and working within established budget and cost guidelines. Many comments regarding a lack of trained staff and a difficulty obtaining certified reference standards also were mentioned.

When asked how they decide which aspects of an HPLC method should be tested for robustness, many people responded that they look at the HPLC method and try to determine the most critical parameters affecting the separation, and the majority of respondents seemed to have a pretty good understanding of the typical HPLC variables to evaluate. It was a little troubling to see that many people rely on regulatory guidelines that only provide limited suggestions for the types of method parameters to investigate, although many carried out robustness studies according to internal standard operating procedures (SOPs).

When asked about whether these challenges will change in the future, the respondents were a decidedly pessimistic bunch. Although many stated that they thought new and different technology will help, this optimism was overwhelmed by comments on the increasing complexity of the products to be analyzed, the lower detection and quantitation limits required by low-dose, high-strength formulations, increased regulatory oversight, pharmaceutical industry business models that use parallel development and shared resources, and the continued desire to decrease product time to market.

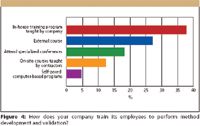

Training and Job Security

Documented training, either by education or experience, is an important part of the quality system in a regulated environment and therefore, questions related to training and approaches to stay current with method validation topics also were included in the survey. The breakdown of how respondents' companies provide for training for people working in the method validation field is highlighted in Figure 4. As Figure 4 illustrates, the majority of companies feel comfortable outsourcing their training in one form or another.

Figure 4

The majority (>50%) of the respondents stay current with method validation by reading the literature, including various journals and LCGC. Conference and seminars are the primary source for 20%, and a much smaller number (<10%) rely on the internet, a number that was surprisingly low.

Biotechnology

It also was evident from the survey that training in the area of HPLC method validation for biotherapeutics (for example, peptides and proteins) is becoming increasingly important. This area gets a little confusing at times because many companies, while calling themselves biotech, are actually based upon a portfolio of small molecule synthetic drugs. Over 80% said that training in the biotherapeutic area is important (20.4%), very important (37.0%), or extremely important (21.9%). Based upon the author's experiences however, demands in the area of biotechnology-related training will only increase, especially with the growth of biogenerics and the increased use of mass spectrometry (MS).

Mass Spectrometry

Responses to a survey question designed to probe the importance of MS in HPLC method validation highlighted the increased dependence upon MS in the regulated environment, particularly HPLC–MS-MS. Over 85% said that gaining more experience in HPLC–MS-MS was important (29%), very important (30.9%), or extremely important (25.1%). Corresponding numbers for gas chromatography (GC)–MS were only slightly lower. These numbers are reassuring as more and more analytical methods are routinely being developed and validated for LC–MS or variations thereof. It is important that analysts recognize the increasing importance of knowing about MS analytical method validation in the future. It was interesting, however, that MS was not mentioned at all during comments on helping to save time, provide valuable information for the most challenging application mentioned, methods validated for the analysis of degradation products and impurities, or answer challenges in the future with complex samples, sample matrices, or sensitivity and specificity issues.

Future Topics and Guest Editors

In the last two questions posed, respondents were asked about future topics for "Validation Viewpoint," and being recruited to guest-author future "Validation Viewpoint" columns. While it is not possible to list all of the suggestions, there were quite a few general areas suggested for future columns, and a lot of material for a future FAQ column or two. However, a surprising number of requests were received for basic method validation information, direct from the guidelines or case studies. LCGC has been publishing the "Validation Viewpoint" column for over 10 years, and many of the early columns dealt with the nuts-and-bolts basics of method validation. Based upon the survey results, it appears that some of these earlier columns should be revisited and updated for today's regulatory climate. In addition, several other areas received multiple mentions deserving of future columns, for example, validating bioanalytical methods, methods for biotherapeutics, troubleshooting and pitfalls, new technology, and automation to save time, experimental design, and robustness to name a few.

Finally, a surprising number of people expressed interest in guest-editing a future "Validation Viewpoint" column. Rest assured you will all be contacted soon to discuss addressing the myriad suggestions for future columns. Thank you to all who responded.

Michael E. Swartz "Validation Viewpoint" Co-Editor Michael E. Swartz is Research Director at Synomics Pharmaceutical Services, Wareham, Massachusetts, and a member of LCGC's editorial advisory board.

Ira S. Krull "Validation Viewpoint" Co-Editor Ira S. Krull is an Associate Professor of chemistry at Northeastern University, Boston, Massachusetts, and a member of LCGC's editorial advisory board.

The columnists regret that time constraints prevent them from responding to individual reader queries. However, readers are welcome to submit specific questions and problems, which the columnists may address in future columns. Direct correspondence about this column to "Validation Viewpoint," LCGC, Woodbridge Corporate Plaza, 485 Route 1 South, Building F, First Floor, Iselin, NJ 08830, e-mail lcgcedit@lcgcmag.com

New Study Reviews Chromatography Methods for Flavonoid Analysis

April 21st 2025Flavonoids are widely used metabolites that carry out various functions in different industries, such as food and cosmetics. Detecting, separating, and quantifying them in fruit species can be a complicated process.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)