UV Detector Problems

UV detectors are the most common LC detector, and perhaps the most reliable ones. But they are not without problems.

Ultraviolet (UV) detectors are the most common liquid chromatography (LC) detector, and perhaps the most reliable ones. But they are not without problems.

I recently received an e-mail question from a reader complaining of a leaking detector cell in the ultraviolet (UV) detector attached to his liquid chromatography (LC) system. This seems like a good opportunity to address that specific question, other UV detector problems, and some of the more recent advances in detector design. Although the present discussion centres on UV detectors, many aspects will apply to other optical detectors, such as fluorescence or refractive index detectors.

Detector Design

First, let's take a look at how the typical detector cell is constructed and we'll be able to see where leakage can occur. After we have that information, correcting the problem should be straightforward.

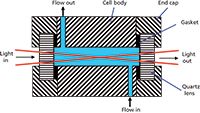

For UV detectors designed to operate with conventional LC systems with upper pressure limits of 6000 psi (400 bar), the construction shown in Figure 1 is common. The cell itself is made by drilling a 1-mm hole through a 10-mm-long block of stainless steel. To contain the liquid, a quartz window is attached to each end of the cell and a seal is formed with a polymeric gasket. The mobile phase needs to pass through the cell, so a provision is made for this by drilling small-diameter (for example, ≤0.125 mm i.d.) holes to connect the outside world with the cell cavity. Most commonly, the entrance and exit holes are on opposite sides and opposite ends of the cell so that the flow path is Z-shaped. This allows efficient washout and clearance of bubbles, should they enter the cell. UV light then passes through the cell from one end to the other. When sample peaks pass through the cell, some of the UV light is absorbed, and a photodiode measures this absorbance by the change in the intensity of light passing through the cell.

Figure 1: Schematic of a conventional UV detector cell. See text for details.

The amount of light passing through the mobile phase at steady state (no sample present) is affected by the refractive index of the mobile phase. Any change in refractive index will result in more or less light making it through the cell, and the baseline will drift or exhibit other disturbances. To help mitigate temperature-related refractive-index disturbances, a heat exchanger is usually fitted to the inlet of the cell. Most commonly this is a stainless steel capillary wrapped around the body of the cell and covered with a heat-conducting material so that the fluid entering the light path is thermally stabilized, and temperature-induced background disturbances are minimized.

Another potential problem is the presence of air bubbles in the flow cell. Even though the mobile phase is usually degassed before use, when the mobile phase leaves the column, it moves from a high-pressure region to a near-atmospheric pressure region. When this happens, any residual air present tends to outgas from the mobile phase and form physical bubbles. When air bubbles enter the flow cell, they disrupt the light path and result in a noise spike or false peak in the chromatogram. Usually, bubbles continue through the flow cell and clear by themselves, but tiny microbubbles sometimes become lodged in the corners of the cell that are less well swept. These bubbles can "bounce" in the flow stream and cause additional baseline problems. To help avoid bubble problems in the cell, pressure can be applied to the cell outlet so that the internal pressure in the cell is sufficient to keep the bubbles in solution. Restricting the flow at the outlet of the flow cell can be somewhat delicate — we want to have enough pressure to keep any bubbles in solution until they leave the cell, but we don't want so much pressure that the cell leaks. The most common practice to provide back pressure on the cell is to use a piece of capillary tubing as the waste line. A narrow capillary will restrict the mobile-phase flow and create pressure upstream. The pressure thus created is dependent on the mobile-phase viscosity, temperature, and flow rate. Because pressure will increase with flow rate, there is a risk that increased pump flow, such as might be used to flush a column, will create sufficient pressure to exceed the flow-cell pressure limits (cell pressure limits should be listed in the "specifications" section of the detector manual, but typically are in the 150-psi or 10-bar region). A better solution to provide back pressure on the cell is to use a back-pressure restrictor that generates a constant pressure. These restrictors are constructed like a spring-loaded check valve that opens when the pressure exceeds a set value less than the detector cell maximum. Back-pressure restrictors can be purchased from most suppliers of LC tubing and fittings.

Correcting Problems

Now that we know how the UV detector cell is constructed, let's look at why problems with cell leakage occur, where they can occur, and how to correct them. The simplest case of leakage is a problem with the tube fitting connecting the column to the detector or detector to waste. The location of leaks at the fittings should be obvious, with fluid dripping from the fitting, although leaks elsewhere in the detector can drain to the fitting before dripping off. Because replacement of the tubing attached to the detector may be difficult or impossible, be very careful when correcting suspected fittings leaks. Support the fitting so that the tubing isn't bent during tightening. Simply tighten the connecting fitting with a wrench or with your fingers, as appropriate. If the leak is not stopped with one-half turn tightening of the fitting there may be additional problems, so don't continue tightening or you may cause permanent damage. At this point loosen the fitting, rinse it with clean solvent, and try again, or simply replace the fitting with a new one. If the connections are made with finger-tightened fittings, I suggest that you set the flow rate to zero, loosen the nut, push the tubing firmly into the connection, and re-tighten it. If you try to tighten finger-tightened fittings with the flow on, the tubing can slip in the fitting, creating a small gap that can cause unwanted peak broadening.

If attempts to correct leaks by tightening the connecting fittings are not successful, it is likely that the gasket forming a seal between the quartz window and the cell body is leaking. Sometimes gasket leaks will occur if the cell is accidently over-pressured, then will correct themselves when the system returns to acceptable pressures. More commonly, however, once the gasket leaks, it continues to leak. Replacement of the cell gaskets may or may not be a user-serviceable operation. Consult the detector operator's manual to see if this is possible. If the cell is user-serviceable, you should be able to buy a repair kit from the detector manufacturer. Instructions on seal replacement should be included with the repair kit or listed in the operator's manual. I recommend replacing both the gaskets and the quartz windows at the same time. Over many hours of use, the quartz windows can deteriorate from exposure to UV light, and organic materials from the sample can degrade or polymerize and coat the windows. If the cell is not user-serviceable, if you feel this is beyond your capabilities, or if you have a service contract on the LC system, call the manufacturer's service technician to make the repair. An intermediate option is to remove the flow cell — usually a simple task — and ship it to the manufacturer for repair.

A much less common problem that can cause leakage is if the heat exchanger leading into the flow cell becomes blocked. The symptom will be excessive back pressure and often leakage at the fitting connecting the column to the cell. Sometimes you can clear such blockages by reversing the flow through the heat exchanger. Because of the pressure sensitivity of the detector cell itself, it is not a good idea to try to back-flush the cell using the LC pump because cell pressure is likely to be exceeded. A better technique is to disconnect both the inlet and outlet connections to the cell and connect a syringe to the inlet of the cell with a high-pressure fitting. Then pull solvent through the cell in the reverse direction of normal flow. This may pull out anything blocking the inlet, but will not apply any pressure to the cell. Do not use the syringe to try to push solvent through the cell because it is too easy to exceed the cell pressure limits. If these attempts don't clear the heat exchanger, call a service technician or send the cell in for factory service.

Cell Cleaning

What about cleaning the detector cell? In my opinion, the detector cell falls in the category of "if it ain't broke, don't fix it". That is, it is much easier to cause damage to the cell than it might appear, so well-intentioned cleaning procedures may cause problems instead of preventing them. You should flush the column after each batch of samples to remove strongly retained materials. These flushing conditions typically involve a high concentration of organic solvent for reversed-phase methods, which is likely to remove anything that might remain in the detector cell, as well. As mentioned above, over time sample components may polymerize or otherwise degrade and coat the cell windows, but for most methods this is not a concern. There are detector cleaning procedures, many of which include flushing with dilute nitric acid. If you decide to follow one of these procedures, consult the detector operator's manual for specific directions, and be sure to wear appropriate protective clothing (for example, a lab coat, eye protection, and gloves). Once again, if there is no apparent problem, I do not think that it is a good idea to perform cell cleaning procedures other than the normal flushing that takes place when the rest of the system is flushed with strong solvents.

Challenges for UHPLC

With the advent of ultrahigh-pressure liquid chromatography (UHPLC), where pressures of up to 19,000 psi (1300 bar) may be encountered, the conventional flow cell described above and in Figure 1 will not work very well. It is likely that the pressure after the mobile phase leaves the column may still be too high for the pressure limits of a conventional cell, so a higher-pressure design is needed. In addition to this, UHPLC columns generate peaks that are typically much narrower than from conventional columns, so extracolumn band broadening caused by the detector may severely compromise the performance of an UHPLC system.

A rule of thumb regarding the relationship between peak width and detector cell volume is that the cell should be less than approximately 10% of the peak volume. Under typical analysis conditions, a 150 mm × 4.6 mm column packed with 5-µm diameter (dp) particles will generate peak volumes of approximately 100 µL when the retention factor (k) is 1. Another popular conventional LC column configuration is 100 mm × 4.6 mm packed with 3-µm particles, which will give approximately 65-µL peaks with k = 1. You can see that these would suggest cell volumes of no more than 6.5–10 µL. So, the 8-µL cell of the conventional 1 mm i.d. × 10 mm long cell is unlikely to contribute unacceptable band broadening, especially if k values of more than 1 are used. On the other hand, a 50 mm × 2.1 mm, 2-µm dp column used with UHPLC will give peaks at k = 1 of about 7 µL in volume, so cells with a volume less than 1 µL will be required to avoid unwanted band spreading.

We could reduce the length of a conventional flow cell to reduce the volume, but this also reduces the sensitivity, because fewer sample molecules will be in the optical path at any given time. Reducing the diameter from 1 mm to 0.5 or 0.25 mm i.d. would reduce the volume from 8 µL to 2 µL or 0.5 µL, respectively. At first glance this seems like a good idea, but there are other problems that are encountered. Any light that enters the flow cell that is not parallel to the cell walls will strike the walls of the cell and tend to be scattered, changing the amount of light that makes it through the cell to the light-sensing photodiode. This can happen if the light is not perfectly collimated or if the refractive index of the mobile phase changes, such as during a gradient or because of temperature or pressure changes. With flow cell diameters of <1 mm, it is difficult to avoid unwanted light scattering within the cell. The net effect is that narrowing a conventional flow cell will not give adequate detector performance.

The innovation that allows UV detection to work with UHPLC is the total internal reflectance, or light-pipe, design shown in Figure 2. In this design, the inside of the flow cell is coated with a reflective material, such as Teflon TF, that efficiently reflects any light rays that contact it. An alternative design uses an uncoated fused-silica capillary, which reflects light from the external surface of the capillary. In either case, the result is that rather than scattering the light, as with a conventional stainless-steel surface, the light bounces off the reflective surface as it goes through the cell and all the light makes it to the other end where it can be measured with the photodiode. Now the cell diameter is no longer a limitation in design, so a 0.25-mm i.d. cell is practical. Therefore, commercial instruments now offer flow cells of <0.5 µL in volume that will work with UHPLC. Because all the incident light makes it through the flow cell, the refractive index-related problems of conventional cells are mitigated. A reduced sensitivity to temperature effects means that the UHPLC flow cell can have a smaller heat exchanger (or none at all), eliminating another potential source of band broadening.

Figure 2: Schematic of a total internal reflectance (or light-pipe) UV detector cell, as used in UHPLC applications. See text for details.

The only complaint I've heard about the light-pipe detector cell design is that the internal coating is somewhat fragile. I've heard reports of damage to the coating when the cell was allowed to dry out and heat up with exposure to the UV lamp. Then when the flow is turned back on, the coating can be washed off, blocking or otherwise ruining the flow cell. Some instruments protect against this by automatically putting a shutter between the lamp and the cell when a run is not underway. If your system uses an internally coated cell and is not protected in this manner, when you turn off the instrument you should make sure the detector lamp is also turned off.

Conclusions

We've looked at the design of the UV detector cell for both conventional and UHPLC applications. With care, both designs can be operated with few problems. With conventional LC systems, the advances in column technology, such as the increasing dependence on 3-µm dp particles and now the growing popularity of core–shell particles, mean that the conventional 1 mm i.d. × 10 mm, 8-µL flow cell is marginal, at best, in terms of extracolumn band broadening effects. For this reason, I predict that the next generation of conventional LC systems designed to operate up to 6000 psi (400 bar) will incorporate light-pipe flow cell designs.

John W. Dolan is vice president of LC Resources, Walnut Creek, California, USA. He is also a member of LCGC Europe's editorial advisory board. Direct correspondence about this column should go to "LC Troubleshooting" LCGC Europe, 4A Bridgegate Pavilion, Chester Business Park, Wrexham Road, Chester, CH4 9QH, UK, or email the editor-in-chief, Alasdair Matheson, at amatheson@advanstar.com

New Method Explored for the Detection of CECs in Crops Irrigated with Contaminated Water

April 30th 2025This new study presents a validated QuEChERS–LC-MS/MS method for detecting eight persistent, mobile, and toxic substances in escarole, tomatoes, and tomato leaves irrigated with contaminated water.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)