UHP-SEC-MALS: Absolute Characterization of Polymers With Light Scattering and UHP-SEC

Ultrahigh-pressure size-exclusion chromatography (UHP-SEC) offers multiple benefits for synthetic polymer characterization. However, despite the many advantages of UHP-SEC, its rapid, low-volume separation is more sensitive to column calibration errors and drift than traditional high performance (HP)-SEC. Additionally, only a small selection of column chemistries are available. It is therefore essential to combine UHP-SEC with online, low-volume multi-angle light scattering instrumentation (UHP-SEC-MALS) to overcome these challenges.

Photo Credit: keren-seg/Shutterstock.com

Daniel Some, Wyatt Technology Corp., Santa Barbara, California, USA

Ultrahigh-pressure size-exclusion chromatography (UHP-SEC) offers multiple benefits for synthetic polymer characterization. However, despite the many advantages of UHP-SEC, its rapid, low-volume separation is more sensitive to column calibration errors and drift than traditional high performance (HP)-SEC. Additionally, only a small selection of column chemistries are available. It is therefore essential to combine UHP-SEC with online, low-volume multi-angle light scattering instrumentation (UHP-SEC-MALS) to overcome these challenges.

Ultrahigh-pressure size-exclusion chromatography (UHP-SEC) is growing in popularity as the technique of choice for analysis of synthetic polymers. With greatly reduced run times and consumption of both sample and solvent, the time- and costâsaving benefits are compelling. Factoring in better resolution in separation and the consequential improvement in quantification of monomers and oligomers, as well as the flexibility to revert to standard gel permeation chromatography (GPC) as necessary, the case for upgrading to a highly productive UHP-SEC system is clear.

With all the advantages of UHP-SEC, several drawbacks need to be addressed. The first is the implicit assumption of a column calibration curve: that different elution times necessarily imply different molar masses, with decreasing molar mass corresponding to increasing elution time. By this logic, a narrow standard would elute in a very narrow peak-narrower than the inherent broadening because of the finite column volume. In reality, even a narrow standard elutes with a width that-theoretically, by column calibration-corresponds to at least a two- to fourfold span in molar mass.

The second drawback is surface chemistry. When optimizing a separation method, it is important to find conditions where both the reference markers and sample to be tested do not interact nonâideally (for example, via hydrophobic or charge interactions) with the column packing. This is because column calibration depends on the assumption that the reference molecules and sample undergo only ideal (steric) interaction with the column, and any additional “stickiness” will render erroneous results. Compared with high performance liquid chromatography (HPLC)-SEC columns, there are relatively few surface chemistries available to UHPâSEC for method optimization, hence a higher probability that the method will not be fully optimized.

The third is column creep and drift in chromatography conditions. With such a fast separation, even a minor difference in elution time because of column ageing, sample loading, or changes to the pump operation conditions will lead to a relatively large error in estimated molecular weight.

Light Scattering

Online multi-angle light scattering (MALS) (1,2) measures polymer molar mass at each elution volume, absolutely, without reference to retention time. It does so by a first-principles physical relationship between the scattered intensity (Isc), molar mass (M), concentration (c), and scattering angle Ï´:

where dn/dc is usually known or readily measurable for a polymer in any given solvent, P(Ï´) is an angular dependence that is dependent on the molecule’s rms radius rg, and the constant of proportionality may be calculated from the measurement system properties such as laser wavelength. Hence measurement of Isc and c directly yields the values of M and rg, contiguously, as the solution passes through the MALS detector’s flow cell. The determination of molecular weight is independent of conformation or shape as well as elution properties. For these reasons, SEC-MALS has long been the de facto standard for rigorous analysis of proteins and polymers in solution separated by standard HPLCâSEC.

With the addition of an embedded dynamic light scattering (DLS) module, SEC-MALS adds a second, independent determination of molecular size (hydrodynamic radius). The relationship between molar mass and molecular size may be analyzed to determine polymer conformation such as random coil, branched, or elongated.

MALS and refractive index (RI) detectors for UHP-SEC have recently become available (3), conferring the benefits of MALS and embedded DLS on the newer separation technology. UHP-SEC-MALS maintains the central benefits of UHPâSEC while preserving chromatographic resolution and providing absolute molecular weight and size of the eluting species.

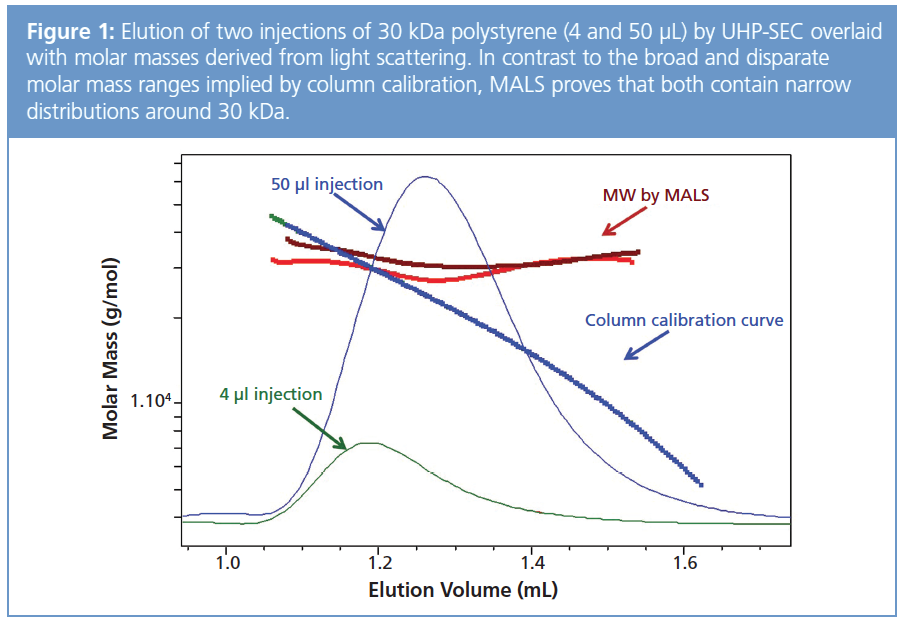

The importance of UHP-SEC-MALS is exemplified in Figure 1, where the chromatograms of a 30 kDa polystyrene standard with two injection volumes are presented. A naïve interpretation of the chromatograms based on elution time would suggest that the 50-µL injection contains primarily smaller species than those in the 4âµL injection. It would also indicate a broad molar mass range covering 10–40 kDa or 20–40 kDa in the respective peaks; yet MALS analysis shows that both injections consisted of narrow distributions around 30 kDa.

Knowns and Unknowns

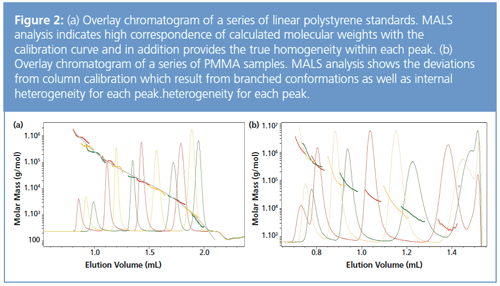

It is always helpful and even essential to validate an unfamiliar technique against commonly accepted standards. For UHPâSEC, such standards are linear polystyrenes, and SEC-MALS analyses of a series of polystyrene standards are quite informative. As shown in Figure 2(a), the molar masses derived by light scattering align perfectly with the column calibration curve. However, the flat MALS results across most of the peaks provide absolute evidence that these polystyrene standards are quite homogeneous, something that could not be proven with column calibration alone.

PMMA, on the other hand, elutes quite differently from linear polystyrene because of branching. As shown in Figure 2(b), the molar masses determined by MALS for these nominally “unknown” samples do not align nicely with each other as for the polystyrene standards, and each peak is quite polydisperse. Nevertheless, MALS provides the full picture in terms of correct, accurate molar masses and distributions across the entire range from hundreds to millions of g/mol.

SEC-MALS and UHP-SEC-MALS

Not only is it essential to validate a new technique against standards, it is also important to compare it against the old technique. For decades, SEC-MALS has been the gold standard for evaluating polymer molar mass and size. While current UHPâSECâMALS instrumentation does not cover the entire size range of standard SECâMALS (MW: 300–109 Da, rms radius: 10–500 nm), it does cover the entire range of UHP-SEC columns (MW: 300–106 Da for linear polymers and higher for branched polymers, rms radius: 10–50 nm). Crossâvalidation has consistently shown excellent agreement between SECâMALS and UHP-SEC-MALS.

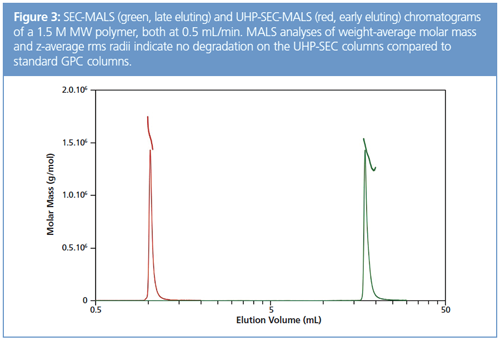

The comparison is particularly illuminating in light of the concerns that have been raised about the potential for shearing polymers under high pressure on a tightly packed UHPâSEC column. Figure 3 presents the analysis of a 1.5 M polystyrene sample, characterized by SEC-MALS (green, lateâeluting chromatogram) and UHPâSECâMALS (red, early eluting chromatogram), both at flow rates of 0.5 mL/min. In both analyses the weightâaverage molar masses came out to precisely (1.56 ± .01) × 106 g/mol, and the z-average rms radii were nearly identical at 63.0 and 61.5 nm, respectively. We could therefore conclude that no shearing occurs, at least under these conditions. Potential for shear at higher flow rates remains to be tested.

Nonlinear Conformation-Not An Obstacle

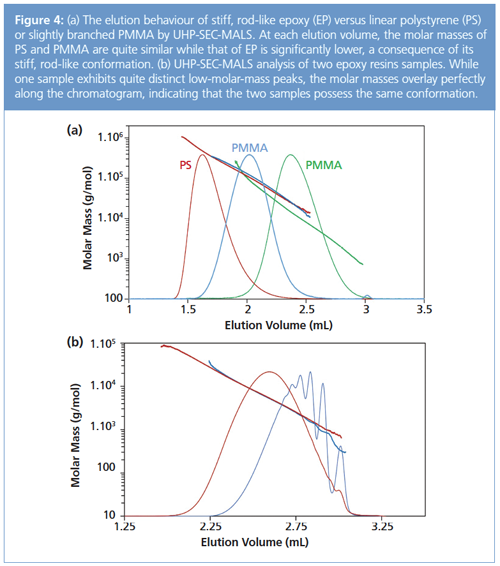

Polymers may take on a variety of conformations, including random coil, branched, and rod-like. Each conformation presents a different relationship between molar mass and hydrodynamic volume, and therefore a different relationship between molar mass and elution volume. Unlike PMMA or polystyrene, some epoxy resins are stiff and elongated, similar to rigid rods. Their elongated shape produces a comparatively large hydrodynamic volume and they therefore elute much earlier for a given molar mass than either of these macromolecules.

Figure 4(a) presents three UHP-SEC chromatograms corresponding to these three polymer types along with the molar masses determined by UHP-SEC-MALS. While this particular PMMA sample is not heavily branched and therefore its molar mass–elution volume relationship diverges only slightly from that of polystyrene, the epoxy resin (EP) is clearly distinguished from the other two. At each elution volume, EP exhibits a molar mass that is about 40–50% lower than the corresponding polystyrene species. The discrepancy in elution behaviour is a direct consequence of the differing conformations. While standard analytical SEC would not recognize the discrepancy, it is highlighted and revealed immediately by MALS and the true molar mass values are determined.

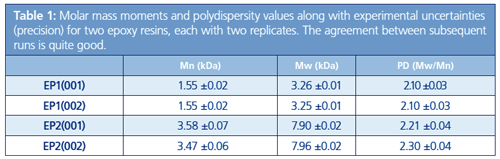

Figure 4(b) presents the chromatograms and overlaid molar mass values determined for two EP samples. The excellent matchup of molar masses along the chromatogram indicate that these resins possess the same conformation, even though they span different ranges and exhibit quite different distribution shapes. The moments and polydispersity values presented in Table 1 indicate very good repeatability for each sample.

One of the most challenging tasks for polymer characterization is the analysis of copolymers. Since no well-characterized, narrow reference standards exist for these quite heterogeneous complexes, analysis by SEC with column calibration is impossible.

Triple detection combining MALS, ultraviolet (UV), and differential refractive index (dRI) is the most common method for analyzing copolymers (4). The combination of two distinct concentration signals is sufficient to determine the copolymer ratio and weight-average dn/dc value, which are then plugged into the light scattering equation (equation 1) to determine the molar mass of each component in the complex as well as the overall molar mass. All the key components of a tripleâdetection system for copolymer analysis are readily available and integrate well in a UHP-SEC format. Hence the standard techniques developed for SEC-MALS are readily extendible to UHP-SEC-MALS.

Experimental

The data presented here were acquired using an Acquity UPLC system with APC 125 and 450 Å SEC columns (Waters Corp.), a µDAWN MALS detector (Wyatt Technology Corp.), and an Optilab UT-rEX refractive index detector for UHPLC (Wyatt Technology), and were analyzed with the ASTRA software (Wyatt Technology). Typical conditions included 4–20 µL injections and 0.5–1.0 mL mL/min flow rate. Additional tests have shown that the elution volume of any given species may vary with flow rate, but molar mass and size as determined by light scattering do not, over a range of flow rates from 0.05 µL/min to 2 mL/min.

Conclusions

UHP-SEC provides many benefits for the characterization of synthetic polymers and other macromolecules ranging in size from hundreds to millions of g/mol. However, these can only be fully realized with the addition of an online light scattering detector for absolute determination of molar mass and size to overcome the inherent limitations of SEC, which may be exacerbated in the context of UHPLC. In addition, UHPâSECâMALS characterizes complex molecules, such as copolymers, branched, or elongated polymers, that do not possess available reference markers. Light scattering is therefore an essential tool for analytical, process development, and quality control laboratories implementing UHP-SEC.

References

- P.J. Wyatt, Analytica Chimica Acta272, 1–40 (1993).

- For brief overview of light scattering as applied to macromolecules and size-exclusion chromatography, see http://www.wyatt.com/Theory

- V.H. Hsieh and P.J. Wyatt, Scientific Reports7, 10030 (2017).

- S.M. Rowland and A.M. Striegel, Analytical Chemistry 84(11), 4812–4820 (2012).

Daniel Some is Principal Scientist at Wyatt Technology Corporation, where he has spent the last 13 years in various roles including R&D, software development, product management, and marketing. Some was previously involved in the development of lightâscattering-based patterned wafer inspection tools for the semiconductor industry.

Characterizing Plant Polysaccharides Using Size-Exclusion Chromatography

April 4th 2025With green chemistry becoming more standardized, Leena Pitkänen of Aalto University analyzed how useful size-exclusion chromatography (SEC) and asymmetric flow field-flow fractionation (AF4) could be in characterizing plant polysaccharides.

Rethinking Chromatography Workflows with AI and Machine Learning

April 1st 2025Interest in applying artificial intelligence (AI) and machine learning (ML) to chromatography is greater than ever. In this article, we discuss data-related barriers to accomplishing this goal and how rethinking chromatography data systems can overcome them.

Influence of Concentration in Conventional GPC/SEC and Advanced Detection GPC/SEC

March 21st 2025Sample concentration is a parameter that can influence the quality of gel permeation chromatography/size-exclusion chromatography (GPC/SEC) separations and the obtained results. Understanding this influence can help to support the development of reliable GPC/SEC methods.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)