Tips & Tricks GPC/SEC: High Temperature GPC versus Ambient GPC

The Column

Gel permeation chromatography/size-exclusion chromatography (GPC/SEC) is the standard technique to determine the molar mass distribution of synthetic macromolecules. However, some kinds of polymers (for example, polyolefins) are often only soluble in special solvents and require high temperatures to be used during the analysis to keep the sample completely dissolved. Therefore, for the analysis of these polymers, dedicated high temperature GPC systems are used. This article will discuss the pros and cons of both high temperature GPC/SEC and ambient GPC/SEC.

phochi/stock.adobe.com

Gel permeation chromatography/size-exclusion chromatography (GPC/SEC) is the standard technique to determine the molar mass distribution of synthetic macromolecules. However, some kinds of polymers (for example, polyolefins) are often only soluble in special solvents and require high temperatures to be used during the analysis to keep the sample completely dissolved. Therefore, for the analysis of these polymers, dedicated high temperature GPC systems are used. This article will discuss the pros and cons of both high temperature GPC/SEC and ambient GPC/SEC.

Synthetic macromolecules are a class of products with very different chemistries ranging from water-soluble, charged molecules, such as polyacrylic acid, to very nonpolar, neutral molecules, such as polystyrene. Typical solvents (and thus the mobile phases applied in gel permeation chromatography/size-exclusion chromatography [GPC/SEC]) therefore range from polar, for example, water, to nonpolar, for example, toluene.

Thanks to easily available highâperformance materials, liquid chromatography (LC) hardware can be used with (or at least adapted to be used with) many of the mobile phases required in GPC/SEC. With optimized components and suitable seals and wear parts in the system it is possible to use the same equipment for many different applications. This is very attractive, especially for laboratories with a lot of different tasks.

However, there are two important exceptions:

- Applications that require very high salt loads or extreme pH values-specific optimized (metal-free/bioinert) hardware might be the better choice.

- Applications that require permanently higher temperatures to keep the dissolved samples in solution. Specialist LC equipment, referred to as high temperature (HT) GPC, is used to meet these specific requirements.

Which Applications Require HT-GPC?

LC requires that the samples be dissolved. This can be particularly difficult for high molar mass samples and crystalline macromolecules.

For crystalline macromolecules the dissolution in an appropriate solvent can be forced when warming up to temperatures slightly below the crystalline melting point. Highly crystalline linear poly(ethylene) (PE) can be dissolved in several solvents (for example, 1,2,4-trichlorobenzene [TCB] or 1,2-dichlorobenzene [o-DCB]) above 160 ºC.

Typical HT applications are therefore polyolefins, such as PE, poly(propylene) (PP), and their copolymers. Those macromolecules are analyzed applying temperatures in the range of 160–210 °C.

Why is Using a Column Thermostat Not Sufficient?

The influence of temperature in GPC/SEC is an interesting topic to discuss. While the GPC/SEC separation mechanism itself is purely entropy-driven and thus independent of the temperature, there are certain important parameters influenced by temperature to consider (1).

Temperature has an effect on sample solubility. As mentioned earlier, for some macromolecules, warming up to temperatures slightly below the crystalline melting point is favourable. However, while low molar mass poly(ethylene glycol) stays in solution once dissolved in THF, most polyolefins in TCB do not. The samples precipitate when the temperature decreases. Thus the sample solution needs to be kept at an elevated temperature for the whole analysis process. As a consequence the sample injection system, the columns and detectors, and all tubings must be kept at higher temperatures.

Which Detection Options are Available?

In general, the detection options for HTâGPC are the same as for ambient GPC/SEC. Typically, at least one concentration detector is required.

Unfortunately UV detection is not an option because of the missing chromophores in nearly all samples that require HT-GPC. Exceptions are ethyleneâvinyl acetate (EVA) or PPâMSAâgrafted copolymers, where UV detection could be useful. However, there is no commercial UV detector on the market that can be attached to or used in HT-GPC equipment.

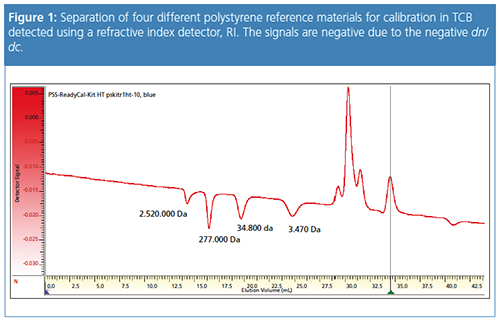

Refractive index (RI) detection is also quite challenging. First of all the refractive index increment, dn/dc, of many samples in the applied solvent is small. Therefore the detector response is low, resulting in small signals. In addition, the RI signal is very sensitive to temperature fluctuations. The combination of these two effects is often the reason for poor raw data quality with RI detection in HT-GPC (compare Figure 1).

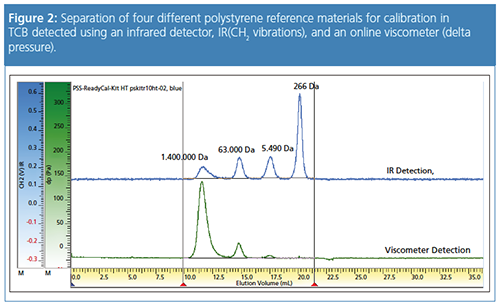

Very interesting detection options for polyolefins are infrared (IR) detection and the use of high-temperature evaporative light scattering (HT-ELSD) detection (compare Figure 2).

While IR detection with flow-through cells is not possible in ambient GPC/SEC because of the solvents applied, typical HTâGPC solvents are IR-transparent. This offers interesting opportunities: CH2/CH3-vibrations can be detected in 1,2,4-trichlorbenzene and 1,2-dichlorobenzene; C=O-vibration can be detected in 1,2-dichlorobenzene. In general, detection of the C-H-vibration in the 3000 cm-1 range gives a linear concentration signal with a good signalâtoânoise (S/N) ratio. Additional information is even available when ratioing two IR-vibrations. This is often used in copolymer characterization to learn more about the comonomer content (2).

HT-ELSD detectors allow for detection of low concentrations, thus reducing the problem of column overloading specifically for high molar mass samples; they can be used for gradient separations of macromolecules (3).

Molar mass sensitive detectors, such as online viscometers and light scattering detectors, are also applied in HT-GPC as additional detectors. As in ambient GPC/SEC, these detectors are used to measure true molar masses and to learn more about branching (4).

Unfortunately the number of narrow distributed polyolefin calibration standards is very limited and only low molar masses are available. Therefore polystyrene is used to calibrate when only sample comparison is required. Universal calibration with online viscometers or light scattering detection is used if true molar masses are required. However, for polyolefins, light scattering detection suffers from the same problem as RI detection with respect to dn/dc (5).

What are the Requirements for Columns?

Typically column stationary phase materials comprise styrene-divinylbenzene, a material that is also quite common in ambient organic GPC/SEC. However, many columns are optimized for the higher temperatures required, so there are specific high temperature columns available.

Of course, heating and cooling processes stress the column stationary phase material. Therefore, to prolong column lifetime, it is recommended to apply low flow rates during heating up and cooling down of columns. The desired flow rate for the analysis itself should be set only when the columns have reached operating temperature. It is also important to never leave the columns at elevated temperatures without flow.

As many polyolefins have a broad molar mass distribution, often column banks are used to ensure that the wide molar mass range is covered with sufficient resolution. This is not unusual when compared to ambient GPC/SEC.

What Else Should be Considered?

Sample preparation for HT-GPC is challenging. A representative sample that can be dissolved without polymer degradation and without initiating reactions during the sample preparation step is required.

As temperature will stress the sample as well as the stationary phase material, it is preferable to limit the sample exposure to higher temperatures to a minimum.

Some samples need to be filtered to remove filling materials like fibreglass or carbon black. Compared to ambient GPC/SEC this step is much more complicated because the filtration needs to be done at the elevated temperatures required to keep the sample in solution. An automated filtering system with backflush cleaning of the filter is a very helpful tool and is a component of some instruments, or alternatively an offline sample preparation device.

As many polyolefins have a broad molar mass distribution and high molar mass, it is recommended to use low concentrations for preparing the sample. To ensure detection with sufficient signal quality the injected mass is increased by adapting the injection volume. An injection volume of 200–300 µL is quite common in HT-GPC, and way above the default 20–100 µL injection volume in ambient GPC/SEC.

It is worth mentioning that solving typical LC problems, which also happen when operating a HT-GPC system, requires much more patience. The system needs to be cooled down to replace frits, columns, or seals. Heating requirements mean that the design of the HT-instruments cannot be as user-friendly as that of ambient GPC/SEC systems, and so checking for leaks and servicing is harder to do. This is also the reason why scientists dedicate one system to HT-applications and use other systems in ambient GPC/SEC.

Summary

- The characterization of polyolefins requires specific HT-GPC hardware; ambient GPC/SEC systems cannot be modified to perform the analysis.

- Autosampler, vials, columns, detectors, and all tubings have to be kept at the high temperature needed to avoid sample precipitation. This high temperature stresses samples, the stationary phase, and the hardware, specifically in the detectors.

- Sample preparation and filtering of the sample is very challenging in HT-GPC because of the high temperatures required to keep the sample in solution.

- Injection conditions for HT-GPC and ambient GPC/SEC are different.

- IR and ELSD are powerful detection options. Other typical ambient GPC/SEC detectors are also used.

References

- D. Held and T. Hofe, The Column5(10), 17–19 (2009).

- P. Montag, The Column4(12), (2008).

- D. Held, The Column 9(18), 2–5 (2013).

- D. Held, The Column8(2), 12–16 (2012).

- D. Held and P. Kilz, The Column5(4), 28–32 (2009).

Daniela Held studied polymer chemistry in Mainz, Germany, and works in the PSS software and instrument department. She is also responsible for education and customer training.

Peter Montag studied chemistry at the University of Duesseldorf, Germany, and received his Ph.D. at the MaxâPlanckâInstitute for Kohlenforschung in the field of metallocene-catalyzed polymerization of polyolefins. He is head of the analytical services department and responsible for HT-GPC contract analysis.

E-mail: DHeld@pss-polymer.com

Website: www.pss-polymer.com

New Method Explored for the Detection of CECs in Crops Irrigated with Contaminated Water

April 30th 2025This new study presents a validated QuEChERS–LC-MS/MS method for detecting eight persistent, mobile, and toxic substances in escarole, tomatoes, and tomato leaves irrigated with contaminated water.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)