Tips for Optimizing Key Parameters in LC–MS

LCGC North America

How to optimize the key variables in LC–MS analysis

The most significant choice in many liquid chromatography–mass spectrometry (LC–MS) methods is the ionization mode. The generally accepted rule is that electrospray ionization (ESI) works best for higher-molecular-weight compounds that are more polar or ionizable, and atmospheric pressure chemical ionization (APCI) is best for lower-molecular-weight, less-polar compounds. Atmospheric pressure photoionization (APPI) was originally designed to work with less-polar analytes; however, the careful choice of dopant or the use of direct ionization sources can significantly extend the capability of APPI techniques. Although these are good rules to help guide you toward the correct ionization technique, you should always treat each analyte independently and (where practical) perform an infusion of your analytes to select the correct ionization technique and polarity (positive or negative ion mode), and then optimize the critical parameters.

To perform this step this you need a 10 mM ammonium formate buffer adjusted to both pH 2.8 and 8.2. Carry out an infusion of your standard or sample through a tee piece at the analytical flow rate, with a 50:50 mix of organic–buffer at pH 8.2 and 2.8, using both negative and positive ionization modes. Use the instrument autotune routine first and then carry out a manual tune on the key parameters-that is, adjust voltages, temperatures, and gas flows to give you the optimum signals under each set of conditions (Table I). From these spectra you will be able to select the optimum ionization mode and eluent composition.

When tuning key parameters that can generate a response curve (for example, ESI source voltages, flow rates, and temperature), setting the value to a maximum may not give you the most robust method. Instead, you should set values on a maximum plateau where small changes in that particular variable will not produce a large change in instrument response.

If you are carrying out a selected reaction monitoring (SRM) experiment, you can now optimize the SRM conditions. Using the optimum ionization mode and eluent composition, adjust the collision energy (CE) voltage to give the product ions; you should be left with 10–15% of the parent ion. You will want to use the product ions that give you the highest response.

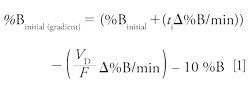

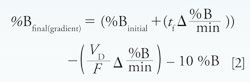

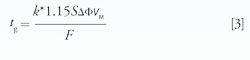

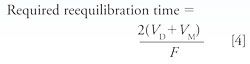

Now to optimize the high performance liquid chromatography (HPLC)–MS method. Start with a high concentration of your standard (for example, 1 µg/mL). Run a 5–100% B gradient using the optimized mobile phase (that is, acetonitrile-ammonium formate buffer at the optimum pH, either 2.8 or 8.2), ionization mode, and SRM transitions. At this point, you should hopefully get a good total ion chromatogram (TIC) and optimum MS spectra for your analytes. The method can be further optimized to reduce analysis time by calculating values for initial %B, final %B, gradient time (tg), and reequilibration time (see equations 1–4).

where ti and tf are the elution time of the initial and final peaks (min), Δ%B/min is the rate of change of the mobile phase during the gradient, VD is the dwell volume (mL), F is the flow rate (mL/min), tg is the gradient time (min), k* is the gradient retention factor (use 5 as a starting point), S is the shape selectivity factor (for small molecules use 5 or calculate using the molecular weight S = 0.25MW0.25), Δφ is the change in %B expressed as a decimal, and VM is the column interstitial volume (mL).

LC–MS still relies on a good chromatographic separation before MS detection. When using single-ion monitoring (SIM) or SRM many quantitative problems are caused by coeluted substances entering the ion source with the analyte of interest, causing ionization efficiency issues. Therefore, it is a good idea to run a full scan acquisition on a representative sample to visualize any potential coelution problems. Quantitation issues do not solely lie with the mass spectrometer but often result from ineffective sample preparation or chromatographic separation.

Silvia Radenkovic on Building Connections in the Scientific Community

April 11th 2025In the second part of our conversation with Silvia Radenkovic, she shares insights into her involvement in scientific organizations and offers advice for young scientists looking to engage more in scientific organizations.