Three-Dimensional Thinking

The Column spoke to Noor Abdulhussain from the University of Amsterdam, about her research on 3D-printing in separation science.

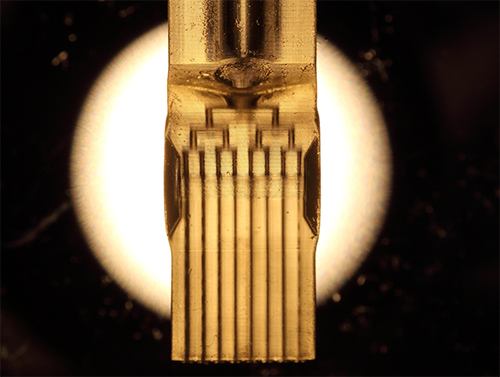

Photo Credit: Courtney of Suhas Nawada, University of Amsterdam, Amsterdam, The Netherlands

Q. The chromatographic possibilities of 3D-printing technologies have slowly edged their way into analytical chemistry in the past decade. What is it about this technology that has chromatographers excited?

A: In recent years, additive manufacturing or 3D-printing, has gained popularity as a fabrication tool in many fields. It is now commonly viewed not only a prototyping tool but as an approach to obtain a final, customized product. Over time, 3D-printing technology has advanced and been adapted to a broad range of materials that could not stay unnoticed by the field of analytical chemistry. The availability and accessibility of 3D-printers make them an attractive alternative for producing column components, such as column cartridges or customized microfluidic (or “millifluidic”) housings with alternative formats. 3D-printing also presents the opportunity to design chromatographic beds.

Additionally, the move from single‑column chromatography to comprehensive two‑dimensional chromatography (2D-LC) to increase the peak capacity is an evolving field within analytical chemistry. Moreover, within the STAMP project (Separation Technology for A Million Peaks), the aim is to achieve spatial three-dimensional liquid chromatography (3D-LC) separation that can offer a solution to achieve peak capacities in the order of a million. These separations are envisaged to be achieved in a three‑dimensional separation device. A novel way to produce efficient separation devices can be established using 3D-printing technologies. The growth in 3D-printers becoming more affordable and accessible, and their resolution, speed, and broad material flexibility continue to be attractive for chromatographers to bring fresh ideas for chromatographic columns developments and other applications in the separation sciences.

Q. What do you regard as the most important developments in 3D-printing in relation to chromatography so far?

A: Interestingly, 3D-printing has entered many areas within the field of chromatography. The opportunity to design chromatographic beds through 3D-printing is an interesting development. The first example of a 3D-printed chromatography column was presented by Fee et al., with packed beds designed in a simple cubic arrangement of spherical particles (1). Another interesting development is the ability to create transparent fused-silica glass components using stereolithography 3D-printers. Frederik Kotz et al. described a 3D-printing process for creating highly-quality components. They were able to design complex shapes of highly transparent, temperature- and chemical-resistant glass on the macro- and micro scale (2). This work widens the choice of materials for 3D-printing, enabling the creation of the arbitrary macro- and microstructures in fused‑silica glass for many applications in both industry and academia.

Another interesting development regarding material is the use of selective laser melting (SLM). 3D-printing in metals and alloys was presented by the group of Brett Paull, where a polymer monolith is fabricated within a printed titanium-coiled column (3,4). SLM provides the opportunity to create new columns housing design of varying degrees of complexity, such as 2D serpentine, 3D spiral, and 3D serpentine column. The use of titanium as a material with high thermal conductivity and suitable surface chemistry to fabricate monolith material within the housing was employed in printed devices described by Passamonti et al. Here, they demonstrated a method in which thermally-initiated polymeric monolithic stationary phases were fabricated within discrete regions of 3D-printed titanium devices. The devices were created with controllable hot and cold regions (5). Development in column design, such as folded or coiled column has pushed the boundaries for multidimensional chromatography. Wouters et al., designed a spatial 3D-LC device where the three separation dimensions were fitted onto a reasonably small area, such as a microchip (6). Another potential design for spatial 3D-LC was proposed by Adampoulou et al., (7,8).

Q. Your recent paper focused on the creation of polymer monoliths within a printed channel. Why did you choose this particular approach?

A: To seamlessly use 3D-printing to produce analytical or chromatographic devices, it is necessary to incorporate stationary phases in-situ in the designed channels. One feasible way to achieve this, in complex geometries, is to synthesize polymer monoliths within the printed channels. Polymer monoliths have been investigated extensively over the past 30 years because of their ease of preparation, affordability, and applicability to many different mould types. Inorganic moulds or housings where polymeric monoliths have been successfully created include fused-silica capillaries and tubes, glass slides (9), and titanium (4,10), while organic housings include cyclic olefin copolymer (COC; chips and tubes) (11) and polypropylene (PP; pipette tips and tubes) (12). The idea behind the recent paper was quite straightforward. We aimed to print in-house the PP channels in an affordable and time-efficient way and fabricate the polymer monoliths for separation.

Q. To create the polymer monoliths, you used a 3D-printing technique called ‘Fused-deposition modelling’. What exactly is fused-deposition modelling? And why is it preferred over other methods?

A: Fused-deposition modeling (FDM) is one of the most widespread additive manufacturing technologies. It is an extrusion-based technique where layers of heated thermoplastic (filament) are deposited, fused, and stacked in layers on the build platform resulting in the printed 3D object. In a detailed way, the filament is heated past their glass transition temperature to a molten state and then extruded through the nozzle (various diameter) of the 3D-printer. The nozzle head can move in an x-y direction to deposit the extruded thermoplastic on the build platform. The material is deposited layer-by-layer until the required 3D object is achieved. During the layering process, the printer nozzle navigates in the x-y direction based on the spatial coordinates of the CAD model in the G-code file, until the desired object is printed.

The main reasons for the preference of the FDM-printed method over the other printers are the ability to create objects with various shapes with the low-cost instrument and material costs; no need for chemical post-processing; no resins to cure; and a broad range of materials that can be used to produce prints of high purity. The result is an easily tuneable, cost-effective process.

Q. The materials used to create chromatographic devices using 3D-printing are obviously key. What are the best options currently available? And is there room for further research into this area to perhaps create more specialised materials for analytical chemistry?

A: Unfortunately, the use of 3D-printed analytical devices for chromatographic purposes are limited by the solvent compatibility of some materials. Materials for 3D-printing technology is a major challenge regarding the field of chromatography. The 3D-printed parts must have excellent mechanical properties to withstand the typical pressure of HPLC conditions. Another challenge is the solvent compatibility against organic solvent that is typically used within chromatography. Even though, there is broad range of materials for 3D printing on the market, such as metals, ceramic and polymers, they are unfortunately not developed for chromatography. Moreover, the materials used for 3D-printers can also contain some additives, fillers, and other unknown compounds that might interact or interfere with chromatographic purposes or during the modification of the inner wall of a printed channel. Simon and Dimartino have developed a novel way to overcome some of the above mentioned challenges [13]. They demonstrated a potential way to directly print a fully functional stationary phase, monolithic adsorbent, through DLP printer for the separations of proteins. The 3D-printed anion exchange structures were tested for adsorption of proteins (BSA) as well as proteins contained in cell cultures, revealing excellent adsorption characteristics. At the moment the best options that are currently available that can overcome the previously mentioned challenges could be metal-printed parts, such as stainless steel or titanium, because they can provide pressure resistance and solvent compatibility by selective laser melting (SLM) printers. The use of these materials leads to transparency issues as well as issues with the internal surface of the device which may not have a smooth surface. However, the latter can be overcome with polishing methods. Another option that can be used is fused-silica-glass-printed parts as mentioned earlier and devloped by Frederik Kotz et al., (2). The same group also developed highly fluorinated perfluoropolyether (PFPE) methacrylates for transparent and chemically-resistant microfluidic chips, they developed photocurable resin formulations that can be printed in commercial benchtop stereolithography printers. They printed a great variety of microfluidic mixers using stereolithography (14). The development of compatible materials for both 3D-printing and chromatography purposes is a challenging field that is still growing. Material with appropriate chemistry for chromatography and with excellent physical properties for 3D-printing will need to continue to be developed in the future.

Q. What issues did you encounter during the creation of the polymer monoliths and how did you overcome them?

A: The main issue we encountered in the research regarding the fabrication of the polymer monoliths in the printed channels is the water tightness of the 3D-printed columns which are mostly related to the material and the FDM printers. We started the research by printing the column using a standard polypropylene (PP) filament with an FDM printer. However, FDM printing technology has some drawbacks regarding the 3D-printed channels. Here, we encountered the first issues with the water tightness of the material. For example, voids introduced during the production phase greatly affect the strength of the printed object. For the standard PP channels, such voids meant that backpressure exceeding 30 bar led to approximately 30–50% loss of flow through the column housing and the connector ports. This prohibits a meaningful analysis of the backpressure and permeability of the monolith created in the standard PP‑filament housing.

This issue could be partly ameliorated by changing printing parameters, such as the filament flow and the orientation (“lay”) of the printed lines (15). Optimizing the printing process results in channels that are adequate for the low pressures generally used in microfluidic applications, but won’t suffice for pressures used in high-performance liquid chromatography (HPLC). Low-pressure applications with regular FDM printers have limits such as warping due to the crystallinity of the PP material. We could overcome this issue by changing to a FDM printer with a heated chamber to control the change in crystallinity better during the print, the result being more pressure-resistant columns.

We also moved to another filament material, the glass-reinforced polypropylene (GPP) filament consists of 30% glass fibres, 68% PP, and 2% additives. The combination of the GPP material and FDM printer with a heated chamber resulted in printed devices with a minimized warping effect and the formation of internal pores within the housings.

Despite the use of a stronger filament and a more robust printing method, voids within the printed pieces were not completely eliminated. However, it was sufficient enough to perform permeability and back-pressure studies.

Q. During your research you compared a few examples of 3D-printed columns. What were the conclusions from your research?

A: During our research two different materials were compared: a regular (“standard”) polypropylene (PP) material and a glass‑reinforced polypropylene (GPP) for printing column housings. In both types of housings, acrylate-based and polystyrene‑based monoliths were successfully fabricated with good wall attachment. Two approaches were used for monolith fabrication: (i) in standard polypropylene (PP) a two-step process was developed, with a radical initiated wall-modification, followed by a polymerization step to generate the monolith; (ii) for glass-reinforced PP (GPP) a silanization step or wall modification preceded the polymerization reaction.

Within the GPP-printed housing, SEM micrographs showed a radially homogenous monolithic structure compared to the monolithic structure in the regular PP housing. The columns prepared in standard PP showed lower pressure resistance as a result of voids in the PP-printed housing. Moreover, the monolith structure in the standard PP housing has larger globules, ranging from approximately 0.7 to 3.8 μm, and exhibits significant inhomogeneity across the column conduit. The GPP-housed monoliths showed a stable permeability for flow rates up to 500 μL/min, although they exhibited some swelling with different organic solvents. The separation was achieved with a mixture of small molecules, although without baseline separation.

Q. What issues still exist that need to be addressed for 3D-printed columns to become a standard tool in analytical chemistry?

A: For the FDM-printing technology, some drawbacks can be addressed regarding the 3D-printed channels. In the search to understand the functional capabilities and limitations of FDM-manufactured components, control over their structural behavior is crucial. For example, voids introduced during the production phase are a large contributor to anisotropy. Moreover, various printing parameters can directly affect some performance characteristics of 3D-printed components, such as surface texture, component strength, thermal properties, and physical properties. To address issues such as voids in the 3D-printed materials, post-processing can be used, such as (i) mechanical deformation via sanding or polishing, and (ii) sealing via chemical vaporization or coating applications. Moreover, the FDM printers are limited by their low resolution which is not suitable for the chromatographic application.

Printing columns using different printing methods, such as digital light processing –stereolithography (DLP-SLA) printing techniques, also present challenges as the compatibility of the material towards organic solvents is an issue that needs to be addressed. Currently, ambiguous composition lists are reported by manufacturers which makes material selection a challenge.

Q. Do you see any application for the techniques developed during your research outside of column fabrication such as in sample preparation, injection, or in hyphenation?

A: Potentially, FDM can be used to produce columns in-house, for a fraction of the cost, with the ability to specify bespoke (on-demand) column dimensions. The method reported can serve as the template for designing 3D-printed devices with monolithic stationary phases for a wide variety of applications. New insights for further applications can be obtained by extending this work to create monoliths in confined parts of more complex printed objects or for applications in solid-phase extraction (SPE) or immobilized-enzyme reactors (IMERs). Calderilla et al., developed a modular device, disk-based SPE, fabricated using stereolithography 3D-printing. The devices are directly connected to a flow-based analytical, instrumentation, replacing typical flow networks based on discrete elements (16). Moreover, in the field of bioscience 3D-printing hasn’t stayed unnoticed. The group of Chen Kuan et al., manufactured bioreactors using a commercial FDM-type 3D-printer and developed a simple procedure to functionalize the printed ABS reactors to facilitate the determination of glucose and lactate in biological samples (17). The same group also developed a 3D-printed cartridge to expand the applicability of paper spray ionization (18). These examples demonstrate the utilization of a 3D-printer as a fabrication method with some advantages, such as low cost, fast production time (no workshop required), and the applicability to fast prototyping and different applications.

Q. Is there room for innovation on the 3D-printing machines themselves which could improve their performance in their capacity to create tools for separation science?

A: 3D-printing presents the opportunity to design chromatographic beds and to produce highly ordered packed beds. However, there is still room for improvement regarding the resolution, speed, and materials of the printers. To match the resolution of the chromatographic requirement high-resolution printers are needed. Nowadays, high-resolution 3D-printing technology exists, for example, projection micro stereolithography (PµSL) or two-photon photopolymerization (TPP). There is still a major variance between nominal resolution and practical achievable printed size (1,19). While printers like TPP can achieve high-resolution it will be at the cost of time and speed, therefore long printing times are required to be able to print with high-resolution.

Q. When do you think 3D-printed products will be commercially available for chromatographers and in what areas?

A: Future improvements in 3D-printers will be required to overcome some key challenges that will allow products to become commercially available. At the moment 3D-printed parts, such as mixers are commercially available to achieve optimal fluid mixing performance in

HPLC and bioprocessing applications. However, for complex microfluidic platforms that require less resolution,

the 3D-printed products are expected to be available in less than a decade. I have to say that no one should expect 3D-printing to do magic tricks, it is like any other production method and an addition to expand the boundaries of separation sciences.

References

- C. Fee, S. Nawada, & S. Dimartino, J. Chromatogr. A. 1333, 18–24 (2014). https://doi.org/10.1016/j.chroma.2014.01.043.

- F. Kotz et al., Nature. 544, 337–339 (2017). https://doi.org/10.1038/nature22061.

- V. Gupta et al., Anal. Chim. Acta. 910, 84–94 (2016). https://doi.org/10.1016/j.aca.2016.01.012.

- V. Gupta et al., Anal. Chem. 90, 1186–1194 (2018). https://doi.org/10.1021/acs.analchem.7b03778.

- M. Passamonti et al., Anal. Chem. (2020). https://doi.org/10.1021/acs.analchem.9b04298.

- B. Wouters et al., Lab Chip. 15, 4415–4422 (2015). https://doi.org/10.1039/c5lc01169h.

- T. Adamopoulou et al., J. Chromatogr. A. 1612, 1–10 (2020). https://doi.org/10.1016/j.chroma.2019.460665.

- T. Adamopoulou et al., J. Chromatogr. A. 1577, 120–123 (2018). https://doi.org/10.1016/j.chroma.2018.09.054.

- I. Urbanova & F. Svec, J. Sep. Sci. 34, 2345–2351 (2011). https://doi.org/10.1002/jssc.201100202.

- E.P. Nesterenko et al., J. Chromatogr. A. (2010). https://doi.org/10.1016/j.chroma.2010.02.007.

- Y. Ladner & A. Bruchet, Lab on a Chip 6, 1680–1685 (2012). https://doi.org/10.1039/c2lc21211k.

- H. Alwael et al., Analyst 136, 2619–2628 (2011). https://doi.org/10.1039/c1an15137a.

- U. Simon & S. Dimartino, J. Chromatogr. A. 1587, 119–128 (2019). https://doi.org/10.1016/j.chroma.2018.12.017.

- F. Kotz et al., Micromachines 9 (2018). https://doi.org/10.3390/mi9030115.

- G.I.J. Salentijn et al., Anal. Chem. 89, 7053–7061 (2017). https://doi.org/10.1021/acs.analchem.7b00828.

- C. Calderilla et al., Talanta 175, 463–469 (2017). https://doi.org/10.1016/j.talanta.2017.07.028.

- C.K. Su, et al., Anal. Chem. 88, 6265–6273 (2016). https://doi.org/10.1021/acs.analchem.6b00272.

- G.I. Salentijn, H.P. Permentier, & E. Verpoorte, Anal. Chem. 86, 11657–11665 (2014). https://doi.org/10.1021/ac502785j.

- S. Nawada, S. Dimartino, & C. Fee, Chem. Eng. Sci. 164, 90–98 (2017). https://doi.org/10.1016/j.ces.2017.02.012.

Noor Abdulhussain obtained her M.Sc. degree in 2017. She is now a PhD student in the ERC STAMP (Separation Technology for A Million Peaks) project at the University of Amsterdam. Abdulhussain has published on integrated analysis of nanoparticles and the constituting macromolecules by LC×LC. She recently was decorated with a best poster award at HPLC2019 (Milan, Italy), and was invited to give a lecture at the Emerging Separations Technologies symposium (Chromatographic Society, London, UK). While her current work mainly focuses on functionality assessments of 3D-printed devices for application to multi-dimensional separations, Abdulhussain remains involved in studying fundamental separation mechanisms including those of hydrodynamic chromatography and size-exclusion chromatography.

E-mail: n.abdulhussain@uva.nl

Website: www.uva.nl/en

Common Challenges in Nitrosamine Analysis: An LCGC International Peer Exchange

April 15th 2025A recent roundtable discussion featuring Aloka Srinivasan of Raaha, Mayank Bhanti of the United States Pharmacopeia (USP), and Amber Burch of Purisys discussed the challenges surrounding nitrosamine analysis in pharmaceuticals.

Silvia Radenkovic on Building Connections in the Scientific Community

April 11th 2025In the second part of our conversation with Silvia Radenkovic, she shares insights into her involvement in scientific organizations and offers advice for young scientists looking to engage more in scientific organizations.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)