- November 2023

- Volume 41

- Issue 10

- Pages: 404–408

The Evolution of LC Troubleshooting: Strategies for Improving Peak Tailing

Troubleshooting continues to evolve constantly, changing how we overcome issues such as chemical causes of peak tailing.

As chromatography technologies change, our approaches to using them in ways that value reliability, as well as the ways we should approach troubleshooting and fixing problems, should also change. In this installment, we continue the discussion started earlier this year about how some specific troubleshooting topics have evolved over time, this time focusing on chemical causes of peak tailing, and strategies that we can use to overcome them. Understanding how knowledge and technologies related to peak tailing have evolved is helpful for troubleshooting problems with peak shape, designing reliability into new methods, and when considering updates to legacy methods that have been in use for decades.

In recent months, I’ve been hearing from several readers of this column that they’ve appreciated the more educational, “back-to-basics” flavor of some “LC Troubleshooting” installments in the last year. So, in September, I decided to dip a little further into that theme and provide some perspective on the evolution of various troubleshooting topics over the last few decades. My view is that this kind of perspective is particularly valuable to those who are relatively new to the field. There are some aspects of “the way we do things” that may seem peculiar on the surface, but are in fact very important to the reliability of high-performing liquid chromatography (LC) methods. On the other hand, some aspects of certain methods and ways of doing things are simply unnecessary in 2023 because LC technology has evolved in such ways that the old tricks aren’t needed anymore. Sometimes implementing the old tricks with new technology doesn’t do any harm, but they provide no benefits and add cost to analyses because they take time and resources to implement. Thus, we really ought to let them go if they are not adding any value to the method. In other words, let’s be smart about the methods we deploy. If we can’t come up with a better explanation for why something about the method is the way it is, then it’s time to let it go.

In this installment, I will discuss the evolution of knowledge and technologies related to addressing the problem of peak tailing as it relates to basic compounds (that is, compounds that lose protons to the mobile phase when pH is increased) analyzed under reversed-phase (RP) LC conditions. Today, we have a much better—though not fully complete—understanding of the peak tailing phenomenon than we did 20 years ago, and recently introduced column technologies give us more options to try when tailing peaks are observed. It is useful to have a broad sense for how things have changed, as this can impact choices during the development of new methods or the troubleshooting of existing methods. Readers interested in learning more about peak tailing are referred to previous installments of “LC Troubleshooting,” (1,2), Dolan’s book on the subject (3), and a very recent, masterful review article on the topic of peak tailing of basic compounds under RP conditions by McCalley (4).

A Tailing Peak is Just One of Many Possible Poor Peak Shapes

In the June 2022 installment of “LC Troubleshooting,” I surveyed the many different ways a peak can be poorly shaped, including fronting, split, tailing, and negative peaks (5). Although peak tailing is just one way for things to go wrong, it is a very important one, both because it is relatively common in reversed-phase separations of basic compounds, and because it can be one of the more difficult problems to solve. This difficulty is due, at least in part, to the fact that we don’t yet fully understand the tailing phenomenon (see below for more about the state of our understanding), and when we don’t fully understand the problem, our troubleshooting effort is reduced to a mere trial-and-error approach. As was discussed in the November 2021 installment of “LC Troubleshooting,” also about peak tailing in RP separations, we also differentiate between different subtypes of tailing—exponential tailing and overload tailing. Examples of these peak shapes and a comparison to the ideal Gaussian peak shape is shown in Figure 1 (2).

Why Do We Care About Tailing Peaks?

As is shown qualitatively in Figure 1, and quantified using the measure of plate number (N), tailing peaks observed in a chromatogram that is populated with at least some normal peaks will generally be broader than their symmetrical counterparts, particularly toward the base of the peak. This is not desirable for two major reasons. First, the increased width of the peak limits the ability of the method to separate closely eluting peaks, particularly when they appear to the right of the tailing peak, and especially if the neighboring peak is lower in concentration. In these cases, the peak tail like that shown in Figure 1 can effectively obscure a low concentration neighbor. Second, the slow approach of the detector signal to the baseline on the right side of a tailing peak makes it difficult to decide (both for humans and software) where to place the integration endpoint when the method is used for quantitative purposes. This can lead to problems with accuracy or precision of the method. Indeed, this is a major driver for the guidance in Chapter 621 of the U.S. Pharmacoepoeia that specifies that peak asymmetry should be less than 1.8 (6) (see reference [7] for a detailed discussion on the calculation of peak asymmetry; a perfectly symmetrical peak has an asymmetry of 1.0).

Non-Chemical Causes of Peak Tailing

While the chemical causes of peak tailing discussed in this article are very important, it is also important to remember that there can be purely physical causes of tailing peak shapes that have nothing to do with the chemistry. These include poor connections (for example, capillaries connected to valves, columns, heat exchangers, or detectors), mismatches between the sample solvent (that is, the diluent) and the mobile phase composition, and a column that is physically failing due to irregular organization of particles inside the column or fouling of the inlet frit, for example. A fuller discussion of these problems and potential solutions can be found in the September 2021 installment of “LC Troubleshooting” (8).

Troubleshooting Advice for Tailing Peaks circa 2000

In his February 1999 installment of “LC Troubleshooting,” titled “Basic Compounds: Starting on the Right Foot,” John Dolan provided a list of suggestions to consider when developing a method for the separation of basic compounds by RPLC (1). This list, which reflected the state of the art at the time, was intended to maximize the user’s chances of getting a good separation from the start. Much of the article was ultimately dependent on knowledge about the nature of silica-based stationary phases at the time, and the central idea that silanol groups (-Si-OH) at the surface of silica particles can lose protons when the mobile phase pH is increased, leading to a population of negatively charged sites on the silica surface.

The number of these negatively charged sites on the surface, and the pH at which they lose their protons, is affected by several factors, including local surface geometries, the concentration of metal impurities in the bulk silica, and specific processing steps used during manufacturing of the stationary phase. In general, the presence of the negatively charged sites is associated with poor tailing peak shapes for basic compounds. Recognizing this, Dolan made several recommendations, some of which are highly relevant today, and some of which have fallen out of favor because of superior alternatives that have been developed in the intervening years.

- Start with modern column technology. At the time, a distinction was made between newer “type B” silica and older “type A” silica, with a key characteristic of type B being a much lower metal impurity content. This lower metal level reduced the number of highly acidic silanol groups that would deprotonate well below pH 7.

- Work at low pH. Understanding that the equilibrium illustrated in equation 1 is affected by pH, and that negatively charged silanol sites can be largely suppressed by working with mobile phases below pH 3 (even for type A silica), working in the pH range of 2 to 3 is generally helpful (9).

- Add triethylamine (TEA) to the mobile phase. This is the one I vividly remember learning in chromatography school. If something in your sample is interacting with the stationary phase in a bad way, add something to the mobile phase that looks like the analyte. This is the strategy here—adding TEA to an acidic mobile phase effectively floods any negatively charged surface sites with positively charged triethylammonium ions, thereby blocking adverse interactions between analytes that are basic compounds and those sites.

- Eliminate the silica. When all else fails, and if it is suspected that the silica itself is contributing to tailing peaks, try eliminating the silica altogether. This means moving to some other type of column technology, which, in the year 2000, meant choosing a stationary phase based on an organic polymer (for example, polystyrene-divinylbenzene) or particles based on a different metal oxide, such as alumina, titania, or zirconia.

With the exception of the use of TEA, this guidance is still relevant today. To the best of my knowledge, all new silica-based columns introduced into the marketplace today are based on high-purity type B silica; thus, the distinction between types A and B is perhaps not as salient as it once was. The use of TEA, while important in a number of legacy methods, is declining in popularity due to the widespread use of type B silicas, and the introduction of new column technologies (see below) that have made the use of TEA much less necessary. Finally, in most cases, the use of TEA in the mobile phase is considered completely inappropriate when using a mass spectrometric detector.

Improvements in Knowledge and Understanding since 2000

Readers interested in a thorough review of research related to improving our understanding of peak tailing in the specific case of basic analytes separated by RPLC are referred to the recent (and excellent) review article by McCalley (4). He states that while we have learned a lot through the efforts of many different researchers over the past 20 years, “…elucidation of the fundamental principles involved in determining peak asymmetry of bases has vexed the most distinguished researchers in the subject for many years.” In other words, we cannot yet fully explain all the experimental results that have been observed in studies of this problem. Nevertheless, these studies have yielded insights that are practically relevant.

In my view, the most impactful studies during this time have shed light on the factors that influence the overload tailing behavior shown in Figure 1c. Specifically, McCalley’s observation that such overload behavior is observed on silica-based phases both for cationic and anionic analytes is very important. It suggests that not all overload tailing can be explained by implicating the negatively charged silanol sites in a central role in the tailing. This simply does not make sense when the analyte producing the overloaded peaks is an anion. Some other explanation is required. McCalley has proposed a theory of mutual repulsion wherein the adsorption of a small amount of charged analyte (cation or anion) to the stationary phase surface results in repulsion of similarly charged analyte molecules that enter the zone of previously adsorbed analytes, thus leading to broadening of the zone (and the corresponding peak observed at the detector) (10). An important piece of evidence that supports this theory was the observation of such overload tailing even with stationary phases composed completely of organic polymers, which of course cannot have any negatively charged silanol sites (11).

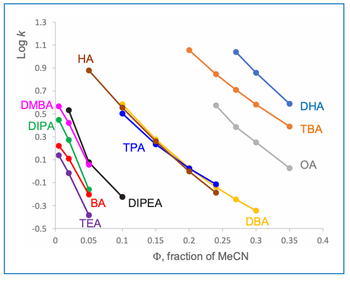

One of the implications of the mutual repulsion theory, if it is correct, is that overload behavior should be strongly dependent on the ionic strength of the mobile phase. Studies from the same time period showed that this is indeed the case (12), and this has important practical consequences, especially when using mass spectrometric detection. Dilute formic acid in water (for example, 0.1%, which is the de facto preferred aqueous mobile phase solvent for ESI-LC–MS) is a low ionic strength solution compared to dilute phosphoric acid or trifluoroacetic acid in water at the same formal concentration. This is because formic acid is a weaker acid, and thus, it dissociates less and produces less of the formate anion and free hydrogen ion compared to stronger acids. Given the low ionic strength of these solutions, severe overload tailing can be observed even at modest analyte concentrations. The good news is that the addition of a modest amount (for example, 10 mM) of ammonium formate (or acetate) to increase the ionic strength of the mobile phase can improve the overloading behavior substantially.

New Column Technologies that Can Be Used to Address Peak Tailing Introduced since 2000

There have been three major developments in column technologies since 2000 that have expanded the list of possible solutions to improve peak tailing of basic compounds when it is encountered.

- Introduction of silica-based phases that are stable above pH 7. Beginning in the early 2000s, column manufacturers started introducing stationary phases that could be used above pH 10 for extended periods of time. Prior to this time, manufacturers advised that silica-based phases should generally be used in the pH range of 2 to 8 to avoid dissolution of the particles. The ability to work at pH levels above 10 meant that it was possible to develop a method using a mobile phase pH where basic analytes would be deprotonated and neutral (provided pKa < 9), rendering all of the discussion above about interactions with negatively charged silanols irrelevant. Over the past 15 years, manufacturers have continued introducing new phases applicable in this application space.

- Introduction of organo-silica hybrid phases that reduce surface silanol concentrations. A different approach, which moves in the direction of “eliminate the silica” recommended by Dolan in 1999—but not entirely—has been the development of organo-silica hybrid particles that incorporate carbon into the particle structure in place of some of the silicon (13). One effect of this strategy is that the concentration of surface silanols is significantly reduced compared to a typical fully silica-based particle.

- Introduction of stationary phases with embedded charged groups that improve overload behavior. A more recent trend has involved the development of stationary phases for RPLC with charged groups deliberately introduced into the stationary phase layer. Several manufacturers now carry at least one phase of this design. Although we do not yet have a thorough understanding of the reasons these phases offer the improvements in peak shape for basic compounds that they do, they are increasingly being used to good effect, and it will be interesting to follow their continued development in the coming years. One example of the improvement in overload behavior that can be realized with such a phase is shown in Figure 2. Remarkably, we see that the mass of analyte that can be injected before half of the limiting (that is, non-overload conditions) plate number is lost increases by about an order of magnitude with the charged-surface hybrid stationary phase.

Summary

In this installment of “LC Troubleshooting,” I’ve reviewed the importance of peak tailing and some of the chemical causes that can lead to these peak shapes. Some of the strategies for overcoming these chemical causes of peak tailing recommended many years ago, including using high-purity silica, working at low pH, and avoiding silica altogether, are still relevant today. Other strategies, such as using triethylamine (TEA) as a mobile phase additive are slowly declining in importance as new column technologies provide superior solutions. Some of these new technologies, including high pH stable silica-based phases, organo-silica phases, and phases with deliberate incorporation of charged groups, are changing the way we approach method development for basic compounds. Understanding the history of these practices and how they have evolved over time is a useful facet of knowledge for aspiring LC troubleshooters.

References

(1) Dolan, J. W. Basic Compounds - Starting on the Right Foot. LCGC 1999, 17 (2), 100–106.

(2) McCalley, D. V.; Stoll, D. R. But My Peaks Are Not Gaussian! Part III: Physicochemical Causes of Peak Tailing. LCGC North Am. 2021, 39 (11), 526-531,539.

(3) Dolan, J. W.; Snyder, L. R. Troubleshooting LC Systems: A Comprehensive Approach to Troubleshooting LC Equipment and Separations; Humana Press, 1989.

(4) McCalley, D. V. Understanding and Managing Peak Shape for Basic Solutes in Reversed-Phase High Performance Liquid Chromatography. Chem. Commun. 2023, 59 (51), 7887–7899. DOI:

(5) Stoll, D. R. Essentials of LC Troubleshooting, III – Those Peaks Don’t Look Right. LCGC North Am. 2022, 40 (6), 244–247. DOI:

(6) U.S. Pharmacopeia <621> - Chromatography, 2023.

(7) Stoll, D. R. But My Peaks Are Not Gaussian! Part I: Basic Concepts in Peak Shape, and the Effect of Extracolumn Connections. LCGC North Am. 2021, 39 (8), 353–362.

(8) Stoll, D. R. But My Peaks Are Not Gaussian! Part II: Physical Causes of Peak Asymmetry. LCGC North Am. 2021, 39 (9), 409–413.

(9) Méndez, A.; Bosch, E.; Rosés, M.; Neue, U. D. Comparison of the Acidity of Residual Silanol Groups in Several Liquid Chromatography Columns. J. Chromatogr. A 2003, 986 (1), 33–44. DOI:

(10) McCalley, D. V. Overload for Ionized Solutes in Reversed-Phase High Performance Liquid Chromatography. Anal. Chem. 2006, 78 (8), 2532–2538. DOI:

(11) Buckenmaier, S. M. C.; McCalley, D. V.; Euerby, M. R. Overloading Study of Bases Using Polymeric RP-HPLC Columns as an Aid to Rationalization of Overloading on Silica-ODS Phases. Anal. Chem. 2002, 74 (18), 4672–4681. DOI:

(12) McCalley, D. V. Rationalization of Retention and Overloading Behavior of Basic Compounds in Reversed-Phase HPLC Using Low Ionic Strength Buffers Suitable for Mass Spectrometric Detection. Anal. Chem. 2003, 75 (14), 3404–3410. DOI:

(13) Cheng, Y.-F.; Walter, T.; Lu, Z.; et al. Hybrid Organic-Inorganic Particle Technology: Breaking through Traditional Barriers of HPLC Separations. LCGC North Am. 2000, 18 (11), 1162–1172.

(14) Fallas, M. M.; Buckenmaier, S. M. C.; McCalley, D. V. A Comparison of Overload Behaviour for Some Sub 2μm Totally Porous and Sub 3μm Shell Particle Columns with Ionised Solutes. J. Chromatogr. A 2012, 1235, 49–59. DOI:

Articles in this issue

Newsletter

Join the global community of analytical scientists who trust LCGC for insights on the latest techniques, trends, and expert solutions in chromatography.