Selecting the Best HPLC Column for Carbohydrate Analysis of Food Samples

The Column

Food carbohydrate content is routinely analyzed to ensure food quality and taste. Over the years many analytical techniques, including thin-layer chromatography (TLC), enzymatic analysis, and gas liquid chromatography (GLC), have been developed that allow qualitative and quantitative analysis of sugars, organic acids, and alcohol in food. Amongst these, ion‑moderated partitioning high performance liquid chromatography (HPLC) has emerged as a very valuable tool and has been used in thousands of published studies. This article describes the various considerations for selecting and optimizing the use of ion-moderated partitioning HPLC analytical columns for carbohydrate analysis in various types of food samples.

Photo Credit: Jimmy Yan/Shutterstock.com

Payal Khandelwal, Mona Chin, and Anna Quinlan, Bio-Rad Laboratories, Hercules, California, USA

Food carbohydrate content is routinely analyzed to ensure food quality and taste. Over the years many analytical techniques, including thin-layer chromatography (TLC), enzymatic analysis, and gas liquid chromatography (GLC), have been developed that allow qualitative and quantitative analysis of sugars, organic acids, and alcohol in food. Amongst these, ionâmoderated partitioning high performance liquid chromatography (HPLC) has emerged as a very valuable tool and has been used in thousands of published studies. This article describes the various considerations for selecting and optimizing the use of ion-moderated partitioning HPLC analytical columns for carbohydrate analysis in various types of food samples.

Ion-moderated partitioning is a high performance liquid chromatography (HPLC) separation technique that can involve ion exclusion, ion exchange, ligand exchange, size-exclusion, reversed phase, or normal phase partitioning, depending on the base bead of the selected chromatography resin. This type of resin, however, predominantly takes advantage of ion exchange, which separates analytes based on charge, and ion exclusion, which separates molecules of interest by polarity or repulsion (1). For this reason, ionâmoderated partitioning chromatography is often referred to as ion chromatography (IC).

Carbohydrate separation is followed by detection on the HPLC system. Detection options include electrochemical detectors (ED), such as conductivity or pulsed amperometric detectors, and in some cases mass spectrometry (MS). The most commonly used detection systems for IC are ultraviolet–visible (UV–vis) or refractive index (RI) detectors.

The Importance of IC in the Food Industry

IC was first used to reduce the hardness of water during the industrial revolution in Europe. Since then, it has been in use for a wide variety of analytes in the pharmaceutical industry and for environmental, agricultural, and biotechnological applications, and biofuel. This analytical tool has also become crucial to the food industry’s efforts to meet increased demands from the FDA and from consumers. IC has been used to demonstrate food safety, meet mandatory and voluntary government standards, ensure quality control of raw materials as well as final products, provide nutrition labels, and identify ingredients (2). In addition, IC is used for continuous R&D efforts in food development and testing.

In the past decade, this has led to the inclusion of chapters on ion chromatography in the United States Pharmacopeia–National Formulary (USP–NF). Many USP–NF test procedures and assays are now available for the identification and quantification of proteins, organic acids, carbohydrates, sugar alcohols, and other analytes that are important factors in the food and wine industry.

Selecting a Suitable Analytical Column

For certain analytes, published USP protocols are available and should be followed. For analytes that do not have an existing protocol, several factors must be considered to select the HPLC analytical column that provides the best resolution for a particular application. Some important considerations are:

- Cross-linkage-The percentage of crossâlinkage should be considered for columns consisting of a polymer-based resin such as styrene divinylbenzene. The higher the percentage of crossâlinkage, the smaller the molecularâweightâfractionation range. Thus, different resins should be chosen for the separation of large biomolecules and small biomolecules. For example, a four percent crossâlinked resin is an ideal choice for oligosaccharides whereas an eight percent cross-linkage would best serve mono-, di-, and tri-saccharide analysis.

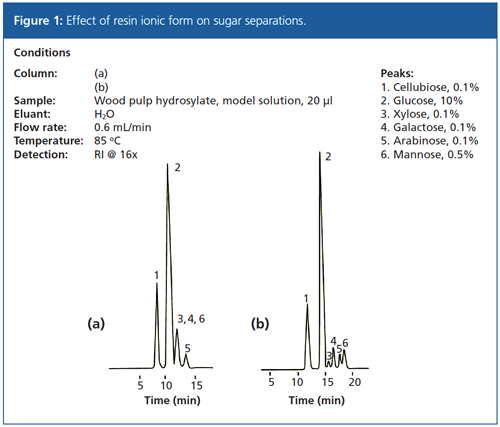

- Resin ionic form-Resin ionic form contributes to selectivity by charge and thus impacts resolution. IC columns are often fixed ionic forms and should not be converted. Inâcolumn conversion leads to swelling and shrinking of the resin, causing unpredictable column behaviour. It is therefore critical to select the appropriate ionic form of the resin for each application. Manufacturer recommendations must be referred to for guidance on selecting the right ionic form. Figure 1 shows the resolution difference of two cationic forms, calcium and lead, to separate the same sample (3).

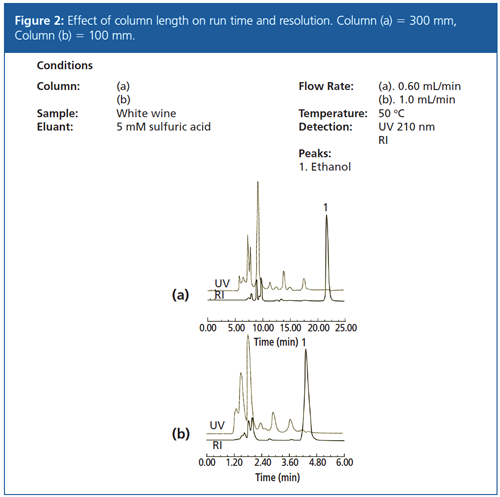

- Column configuration-Column size matters because it affects resolution and analysis time. The minimal amount of resin required must be used to obtain the best resolution. This maximizes selectivity and decreases run times. However, if multiple similar analytes need to be separated, a longer column should be used because the increased residence time on longer columns provides better peak separation of similar species. Figure 2 shows a comparison of run times and resolution of (a) a 300âmm and (b) a 100-mm column. The ethanol (peak 1) from the white wine sample elutes earlier from the shorter column but other components are better resolved on the longer column.

Minimal sample preparation is needed before a sample is loaded onto an ionâmoderated partitioning HPLC column. Usually simple filtration through a 0.45 µm filter suffices. Derivitization is not required here, in contrast to affinity purification.

To prolong the life of IC columns, guard columns are an option. These are smaller versions of the column, which are placed before the main column to absorb components that may foul or damage the main column.

Optimizing the Analysis

After selecting the appropriate analytical column, it is crucial to optimize run conditions. Multiple factors in the run condition can affect the analyte resolution:

- Mobile phase-Polymer-based IC resins, unlike silica-based resins, have the distinct advantage of not being affected by solvents. Water, dilute acid, or organic solvents are used as isocratic mobile phases on these columns. Most carbohydrate separations can be performed with DI water, but the separation of sugar alcohols requires the addition of acetonitrile.

- Elution conditions-The composition of the eluent can be manipulated to adjust the retention times of the compounds of interest. This is accomplished by changing eluent acid strength or adding organic modifiers, to decrease adsorption of organic compounds to the stationary phase. It is recommended to keep the concentration of modifiers as low as possible because they can cause bed shrinkage or swelling.

- Column temperature-Consistent column temperature control for polymer-based IC resins is another critical element. It affects the resin chemistry, column material, and the mobile phase being used. Operating at high temperatures decreases retention time and increases column efficiency. For carbohydrate analysis, high temperature increases the number of theoretical plates and decreases the overall viscosity of the eluents and sample. High temperature also allows deeper penetration of sugars into the core of the resin, allowing size exclusion to contribute to the separation of analytes. All of these factors improve resolution at higher temperatures. In contrast, silicaâbased columns can be operated at a wide range of temperatures, but maintaining the temperature consistency is even more critical here because of their high temperature change sensitivity. Even a 1 °C temperature change affects their resolution capability.

- Flow rate-Each column type has a recommended operating flow rate. While slow flow rates yield better resolution, they can also cause band broadening and long run times. Running at higher flow rates, however, can cause increased back pressure and poor peak symmetry. Follow the column manufacturer’s recommendations to help determine optimal flow rates for each application.

- Detection-It is recommended to use both dual refractive index and UV detection to acquire a complete profile of multiple classes of compounds. Using only a single detection system may lead to generation of incomplete elution profiles.

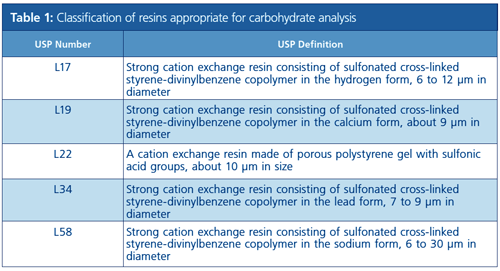

USP Classification

The USP has classified different IC resins into numbers such as L17, L19, L22, L34, and L58. These designations are referred to by the USP–NF as well as other international agencies such as the Food and Agriculture Organization (FAO), Food Chemicals Codex (FCC), and European Pharmacopoeia (Ph. Eur.). Resins appropriate for carbohydrate analysis are classified as seen in Table 1.

Applications of IC Columns in the Food Industry

The food industry is driven by narrow profit margins and requires large production volumes and rapid product turnover. IC has been used for many different applications to support this industry.

Carbohydrate analysis of fermentable sugars (using USP L19 columns) in raw materials, such as corn, directly influences the price of sugar product. Marginal mistakes in determining the sugar composition of corn products can result in significant price variation when translated into thousands of pounds of corn. Sugar profile determination can also help identify food spoilage or degradation by microbes, by detecting sugar byproducts released from microbial metabolism. These quick quality controls of raw materials help food manufacturers save considerable costs.

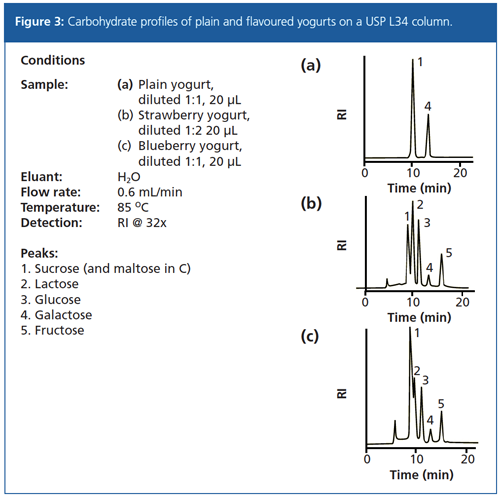

The dairy industry relies on carbohydrate analysis for flavour studies and nutritional assessments. USP L34 is used to assess and quantify different sweeteners added to or naturally occurring in yogurt, milk, and lactose reduced milk. Figure 3 shows the carbohydrate profile for different flavours of yogurt. The three different flavours show different sugar contents and quantities. Such information helps food manufacturers develop food content and nutrition labelling.

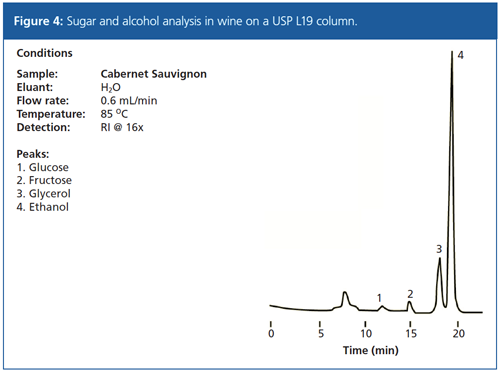

Fermentation analysis of carbohydrates and organic acids is routinely performed by the beer and wine industries. USP L17 columns can separate both these species. USP L19 columns are good for quantitating sugar alcohols in fermentation products (Figure 4). Either column can be paired with an RI monitor to detect carbohydrates, glycerol, and alcohol resulting from fermentation, and a UV monitor to detect carboxylic acids, volatile fatty acids, and other fermentation byproducts. Ethanol and glycerol content of wine are not only excellent indicators of fermentation progression, but they can also be used to predict the quality of the final product. Glycerol content, for example, correlates with the smoothness of the wine.

Sugar and organic acid analysis not only applies to process control and spoilage detection or the detection of food additives, but it can also be used to determine vitamin content and nutritional quality. A common application is the detection of vitamin C (ascorbic acid), which occurs naturally in many food products and is also used as a supplement in fortified foods and drinks. Vitamin C is affected most by food processing and is therefore monitored throughout the process to measure its depletion. It can also be an indicator of the depletion of other nutrients. Vitamin C levels are assessed for fruits and vegetables sold in all forms, fresh, frozen, or canned.

Conclusion

As applications for IC in the food industry have grown, an increasing number of varying HPLC options are available. To take full advantage of this powerful analytical technique, it is important to understand how subtle differences in IC columns or methods can impact column performance. By following the general considerations outlined in this article, IC can be used as a powerful tool to ensure food safety and quality and meet the requirement set forth by the FDA and other food regulation agencies.

References

- T. Jupille et al., Amer. Lab. 13, 80 (1981).

- S. Suzanne Nielsen, Ed., Food Analysis, 5th edition, (Springer, 2017).

- Bio-Rad Laboratories, Bulletin 1928 Rev B, (2012).

Payal Khandelwal, Ph.D., is a Global Product Manager for Protein Purification at Bio-Rad Laboratories.

Mona Chin is a Global Product Manager for Protein Purification Business at BioâRad Laboratories.

Anna Quinlan, Ph.D., is Editorial Manager at Bio-Rad Laboratories.

E-mail: Payal_Khandelwal@Bio-Rad.comWebsite:www.Bio-Rad.com

New Study Reviews Chromatography Methods for Flavonoid Analysis

April 21st 2025Flavonoids are widely used metabolites that carry out various functions in different industries, such as food and cosmetics. Detecting, separating, and quantifying them in fruit species can be a complicated process.

Analytical Challenges in Measuring Migration from Food Contact Materials

November 2nd 2015Food contact materials contain low molecular weight additives and processing aids which can migrate into foods leading to trace levels of contamination. Food safety is ensured through regulations, comprising compositional controls and migration limits, which present a significant analytical challenge to the food industry to ensure compliance and demonstrate due diligence. Of the various analytical approaches, LC-MS/MS has proved to be an essential tool in monitoring migration of target compounds into foods, and more sophisticated approaches such as LC-high resolution MS (Orbitrap) are being increasingly used for untargeted analysis to monitor non-intentionally added substances. This podcast will provide an overview to this area, illustrated with various applications showing current approaches being employed.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)