Recovering from a COVID-19 Shutdown: Tips and Tricks for Starting Up, Part 1

COVID-19-related laboratory shutdowns are sure to cause a myriad of problems with liquid chromatography (LC) instrumentation across the globe. Taking a systematic approach to restarting these systems will save time and money in the long run, by preventing problems that may otherwise appear in days or weeks following startup.

In March of this year, many organizations took unprecedented steps to halt the spread of COVID-19, including severely restricting work in laboratories, or even shutting down entire laboratories, buildings, and work sites for weeks at a time. While some of these shutdowns were planned days in advance and executed well, I have heard many stories from scientists indicating that the shutdowns were sudden, and did not allow time to properly prepare their analytical instrumentation to be idle for weeks or months at a time. Unfortunately, this means that these scientists are going to encounter many challenges when they return to the laboratory, which will necessarily include a lot of troubleshooting to figure out why their systems are not working properly before they can return to their normal experience of producing high quality data.

For this month’s installment of “LC Troubleshooting,” I’ve decided to commit the entire column to providing some tips and tricks that should be useful as scientists go about the process of restarting their laboratories. I’ve invited Tony Taylor to join me in sharing some of the advice and procedures he has developed over the years. Although we’ve never worked through pandemic-related laboratory shutdowns and startups, some of our experiences with troubleshooting liquid chromatography (LC) problems during normal times should prove very useful under these strange circumstances as well.

Dwight Stoll

As we discussed the topics to address in this instalment, we decided to focus on the challenges that are likely to appear most often. When the pandemic has passed, and we all have the chance to discuss problems we encountered and strange observations we made, we’re sure that the list will be very long, and highly diverse. In the following sections we’ve tackled specific aspects of LC systems and their operation, and tried to anticipate the most common shutdown-related problems and their solutions. In next month’s installment, we’ll address other important topics, including column cleaning and health assessment, overall LC system health, and making the decision to start collecting data again.

We strongly encourage you to take care and use a systematic approach to bringing your LC system back on-line. A little effort at this point with preventative measures can save a lot of time and money later on when you are ready to start collecting useful data again. Remember that the column is the heart of any LC system, and arguably the most sensitive to potential shutdown-related problems. Be sure to disconnect the column from the flow path before doing anything else with the system, and only reconnect it to the flow path after you are sure that the rest of the system (that is, solvent bottles, lines, pump, and flow path upstream from the column) is free of contamination and blockages.

A final general cautionary note here is that great care should be taken to avoid precipitation of salts inside the LC system. Aside from evaporation of water from buffer solutions, precipitation of buffer salts can also easily occur when a buffer solution comes into contact with a pure organic solvent. This is because most commonly used buffer salts (although inorganic salts, such as potassium phosphate, are generally worse than organic salts such as ammonium acetate) are highly insoluble in organic solvents, such as methanol and acetonitrile (1). So, one should avoid-at all costs-a situation where an LC system component containing an aqueous buffer is flushed immediately with a pure organic solvent. Such a changeover should involve flushing the buffer first with water, and then the organic solvent.

Solvents and Buffers

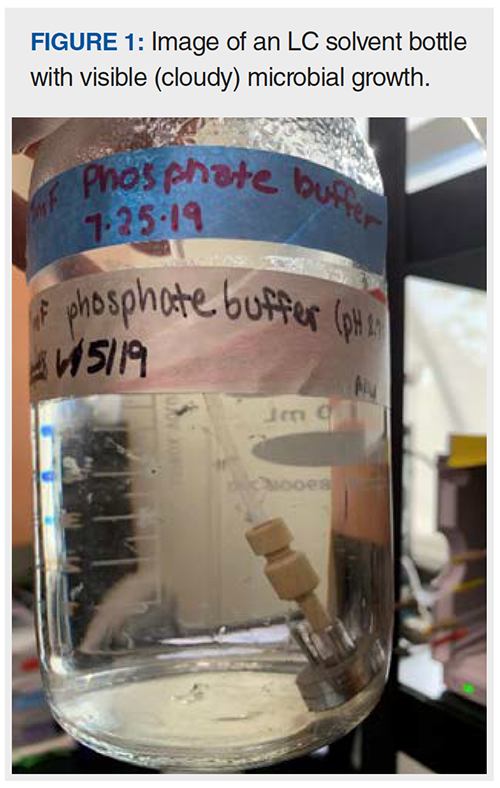

Figure 1 shows a picture of a buffer bottle I observed in an LC laboratory about a year ago. The solution was dilute (1 mM) phosphoric acid in water. Even though this is fairly acidic (pH ~2.7), there was a very healthy microbial community growing inside (affectionately known as “floaties”). The good news in this particular case is that the scientists were able to recover their pumping system without any long-term effects; however, the column they were using at the time suffered a performance loss, and was never quite the same afterwards. We expect that this experience is going to be repeated in hundreds of laboratories as a result of the COVID-related laboratory shutdowns. Many of the aqueous buffer solutions used in LC (and even high-performance liquid chromatography [HPLC] grade water, if given enough time and exposure to laboratory dust) are environments quite favourable to microbes, particularly those in the middle of the pH range. Simply stated, many scientists are going to return to laboratories where they will be able to see visible microbial growth in the solvent bottles of their LCs. So…what to do?

Occasionally we have problems in our own laboratories with solvent bottles that become contaminated somehow, whether resulting from a bad lot of solvent from a vendor, or an instrument operator pouring something into the bottle that does not belong in there. Whenever this happens, our approach depends on whether or not the instrument is using mass spectrometric (MS) detection. If it does, our preference is to simply not use that solvent bottle again for that instrument, because if thoroughly cleaning the bottle requires detergent or other cleaning agents, the potential for problems associated with those cleaning agents is greater than the benefit of having a clean bottle to work with. For example, some detergents can be difficult to remove from glassware, to the point where they are not detectable by MS, and thus what seems like a simple bottle cleaning step can turn into a background contaminant peak in the MS that is detectable for months. When using MS detection, we feel the best solution to a badly-contaminated solvent bottle is a brand new solvent bottle. In other words, just get rid of the contaminated bottle without bothering to try to clean it.

On the other hand, if the contaminated bottle is on an instrument using a less sensitive detector (for example, ultraviolet-visible [UV-vis] spectroscopy or an evaporative light scattering detector [ELSD]), then the bottle can usually be cleaned without major impact on the rest of the system. After discarding the contaminated solvent, wash thoroughly with a detergent designed for use with glassware, rinse four times with HPLC-grade water, and finally with HPLC-grade organic solvent. We find that working through a series of organic solvents of increasing dipolarity-such as cyclohexane, acetonitrile, and methanol (in that order)-is effective for removing contaminants of varying degrees of dipolarity. Before use again on the instrument, be sure to rinse with whatever solvent you plan to put in the bottle.

Now, if you come back to your laboratory and find microbes in your solvent bottles, then the solvent line feeding the pump is also contaminated, in addition to the solvent bottle itself. Before putting this solvent line back into the solvent bottle you have just cleaned, consider what exactly you will do with the solvent line. Again, if this is an LC–MS instrument, you should seriously consider replacing the entire solvent line and solvent inlet filter that goes in the solvent bottle. In any case, if the solvent inlet filter is porous-whether sintered glass or stainless steel-just throw it away, and replace it with a new one. These porous filters are perfect environments to support microbial growth, and getting them truly clean after they have been contaminated is extremely difficult. Inlet filters that are based on screens or mesh are more easily cleaned. Remove the filter from the solvent line, remove the visible debris with a brush, and then soak in detergent, followed by several rinses with water, and finally organic solvent. Sonicating sintered glass filters should be avoided, but sonicating plastic or metal ones is okay. As with the bottle, rinse the filter a few times with the solvent you intend to use it with before putting it in the clean bottle. For the solvent line itself, it is best to remove the line from the pump and attach a syringe (10 mL or so will do) so that you can pull large quantities of rinsing solvent through the line. For older systems that have degasser modules separate from the pump itself, disconnect the solvent line at the pump so that you can pull cleaning solvents through the degasser also. Pulling detergent solution through the degasser should be avoided, because this may persist in the tubing for a long time. We find that using warm water (up to 60 °C) is quite helpful for flushing the internal tubing of the degasser. For newer pumps with integrated degassers, it should be sufficient to disconnect the solvent line at the inlet to the degasser on the pump unit. Using the same steps as with the bottle and filter, pull each liquid through the solvent line as a means of rinsing the inside of the line. For older systems with degassers that have large internal volumes, something on the order of 50 mL of each liquid will be enough to give the solvent line and degasser a good flush. With newer systems where you only need to flush the line external to the pump, 10 mL or so should be good enough.

Dirty and Dried-Out Pumps

Before attempting to move any liquid through the pump itself, it is best to disconnect the high pressure outlet capillary from the pump and connect a waste line running to a waste container to collect whatever goes through the pump until you are confident that the pump is delivering clean, debris-free solvent. If it is obvious that one or more solvent lines has been contaminated with microbes, it will be best to flush the pump thoroughly with clean solvent before connecting the pump to the rest of the system. Our approach to this step is to put all of the solvent lines associated with the pump (typically two for a binary pump or four for a quaternary pump) into a single bottle of HPLC-grade water, and run 30 mL of water through each channel of the pump. Next, put all of the solvent lines into a single bottle of isopropyl alcohol (IPA), and run 30 mL of it through each channel. Finally, move each solvent line back to its respective solvent bottle (for example, one in water, one in buffer, and one in acetonitrile), and flush each channel with 30 mL of the solvent intended for use in the method.

It is important to recognize that there are some filters in modern LC systems that might be easy to overlook. It is always helpful to consult the technical manual for your LC system to see where these might be. For example, some pumps have porous frits or screens on the upstream side of the inlet check valve. Other pumps have porous frits on the downstream side of the outlet check valve. These can also suffer from partial or total obstruction, leading to inconsistent flow (if on the inlet side), or higher than expected pressure (if on the outlet side). If you know you are dealing with a situation where it is likely these filters or screens have been fouled due to prolonged inactivity of the pump, microbial growth, or other debris, it will be a good idea to simply replace these filters or screens at the beginning of your startup process. If you want to try cleaning them before replacing, remove and sonicate in warm water for 10 min, followed by IPA for 10 minutes. If problems persist that are attributed to these parts, just replace them entirely.

If the pump has dried out completely because it was left on with an empty solvent bottle, it can be difficult to remove air bubbles from pump heads during startup. Air bubbles can also accumulate in pump heads if the system is not used for an extended period of time. In our experience, the best way to resolvate a completely dry pump or remove air bubbles from the pump heads is to purge thoroughly with IPA, because it wets most materials used in LC pumps well.

Once the pump has been thoroughly purged with clean solvent and it is delivering the expected flow from each channel at low pressure, it can be connected to the rest of the system. Again, take care to be sure that, if the rest of the system contains a buffer solution, the first solvent pumped from the clean pump to the rest of the system is water, so that precipitation of salts can be avoided.

Component Blockages Due to Precipitation and Debris

Some users will return to their laboratories to find that there is a significant obstruction somewhere in their LC system that is preventing flow at reasonable pressures. This obstruction could result from debris associated with contaminated solvents, pump or valve seal material if salt precipitation occurs in those components, or precipitation of salts inside some other components such as a connecting capillary. The first step in resolving such obstructions is to clean the pump as discussed above, and make sure it will pump water with a waste tube connected directly to the high pressure outlet of the pump. Then, systematically add one connection or component at a time, working your way from the pump outlet toward the detector. In most systems, the next component after the pump will be the autosampler, with a fairly long connecting capillary between them. Disconnect this capillary from the sampler, connect it to the pump, and see if you can pump water through this capillary at reasonable pressure; what pressure is reasonable depends on the dimensions of the capillary. A benchmark to remember is that the pressure drop across a 300 mm length of 120-µm i.d. (0.005 in.) capillary when pumping water at room temperature and 1 mL/min is about 10 bar. If you double the length of this capillary, the expected pressure will double. If you double the diameter, the expected pressure drops by a factor of four. In our experience, it is best to simply replace the capillary if the pressure is more than two times higher than the expected pressure after 5 min of flushing with water. Once you have verified that this capillary is okay, either by flushing or replacing it, then the next likely component is the autosampler itself. Here there are multiple sources of potential obstruction, including the sampler needle and needle seat capillary in the case of a flow-through needle design, or a sample loop capillary if using a fixed volume injection design. If the pressure increases dramatically when the sampler is reconnected, then it is likely that one of these components is obstructed. Occasionally, this can be resolved by removing the capillary and sonicating in warm water, but the easy fix is to simply replace a capillary that you know is obstructed based on the pressure it adds to the system when it is in the flow path. You should keep adding one component at a time to the flow path until you discover the one that is obstructing the flow.

Finding the component in a system that is leading to higher-than-expected pressures can be tricky sometimes, but most of the time the systematic approach described here will identify the culprit.

One other component that deserves special mention here is the flow cell of optical detectors. Most UV and fluorescence detectors have quartz components in contact with the mobile phase that can be damaged if left in contact with highly alkaline solutions for extended periods, or contaminated by microbial growth or other particles that will reduce the transmission of light through the flow cell. Most manufacturers recommend flushing the flow cell with warm water (up to 60 °C), followed by IPA. If excessive noise or poor sensitivity are observed after cleaning, the flow cell windows may have to be replaced.

Summary

Given the variety of ways different laboratories were shut down early on in the global COVID-19 outbreak, it is likely that LC users will encounter a wide variety of problems with their instruments when they return to their laboratories and resume work with their instruments. In this instalment of “LC Troubleshooting”, we have highlighted some of the problems we expect users to encounter most frequently, and made suggestions for resolving these problems in a systematic and efficient way. Taking the time to thoroughly clean and examine your LC system when you return to the laboratory will pay dividends later by avoiding costly interruptions to normal work.

References

- A.P. Schellinger and P.W. Carr, LCGC North Amer.22(6), 544–548 (2004).

Dwight R. Stoll is the editor of “LC Troubleshooting.” Stoll is a professor and the co-chair of chemistry at Gustavus Adolphus College in St. Peter, Minnesota, USA. His primary research focus is on the development of 2D-LC for both targeted and untargeted analyses. He has authored or coauthored more than 60 peer-reviewed publications and four book chapters in separation science and more than 100 conference presentations. He is also a member of LCGC’s editorial advisory board.

Tony Taylor is the Chief Science Officer of Arch Sciences Group and the Technical Director of CHROMacademy.

Direct correspondence to amatheson@mjhlifesciences.com

Determining the Effects of ‘Quantitative Marinating’ on Crayfish Meat with HS-GC-IMS

April 30th 2025A novel method called quantitative marinating (QM) was developed to reduce industrial waste during the processing of crayfish meat, with the taste, flavor, and aroma of crayfish meat processed by various techniques investigated. Headspace-gas chromatography-ion mobility spectrometry (HS-GC-IMS) was used to determine volatile compounds of meat examined.

Accelerating Monoclonal Antibody Quality Control: The Role of LC–MS in Upstream Bioprocessing

This study highlights the promising potential of LC–MS as a powerful tool for mAb quality control within the context of upstream processing.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)