Recent Application and Instrumental Trends in Comprehensive Two-Dimensional Gas Chromatography

This critical review describes recent applications and instrumental trends in comprehensive two-dimensional gas chromatography (GC×GC), with particular (though not exclusive) attention to the period 2018–2019 and that the concept of GC×GC is inherently simple. The maturity of GC×GC and future developments are also discussed.

This critical review describes recent applications and instrumental trends in comprehensive two-dimensional gas chromatography (GC×GC), with particular (though not exclusive) attention to the period 2018–2019 and that the concept of GC×GC is inherently simple. The maturity of GC×GC and future developments are also discussed.

Comprehensive two-dimensional gas chromatography (GC×GC) is the most powerful GC approach available for the analysis of mixtures of volatile compounds. This multidimensional technique was first reported in 1991, and stemmed from the research work of J.B. Phillips (1). Considering that two-dimensional (2D)-GC has been on the analytical scene for nearly 30 years, it can now be defined as “well known”. For this reason, no explanations on the basics of GC×GC are provided in this article. The reader is directed to the many reviews present in the literature, if in-depth details are required (2–5). From consulting such literature, it can be deduced that GC×GC has undergone great hardware and software evolution over the years. For example, during the first 10 years of GC×GC use, flame ionization detection (FID) was, by far, the most common form of detection. After that period, a rapid increase in the use of mass spectrometry (MS) was observed. It was only in 1998 that the first forms of cryogenic modulation (CM) and flow modulation (FM) were introduced (6,7), while in 2003 the first commercial instrument with fully integrated software was proposed (8). Finally, the overall history of GC×GC has been characterized by illustrations of chromatograms highlighting its exceptional separation power. An example was provided by Phillips and Xu (dated 1995) (9), who showed a GC×GC–FID chromatogram of kerosene. The separation was performed on an apolar 10 m × 530 μm, 8-μm df column in the first dimension (1D), and a more polar longer one (25 m × 250 μm) in the second dimension (2D). Each column was housed in a separate GC oven, thus recognizing the importance of independent temperature optimization. A dual-stage thermal modulator linked the two analytical dimensions and was located between the two GC ovens. The transfer device was of simple construction, inasmuch that it was prepared by using a 40 cm × 250 μm, 0.25-μm df apolar column, coated with gold paint. The first stage of modulation was performed on the initial 25 cm of the column segment, while the second stage was performed on the remaining 15 cm. A heating pulse was directed to each modulator segment with a 1 s delay at 60 s intervals. More details on the thermal modulator can be found in the literature (1,10). Compared to current published research, both the column combination (a conventional column was used in the 2D) and the modulation period (60 s) were unusual. Moreover, the temperature gradient was extremely slow (0.1 °C/min) leading to a very long analysis time (it exceeded 800 min), which ended with the elution of alkane C15.

The outstanding potential of GC×GC was clearly evident in these early works (1,9,10), and certainly created great excitement amongst many GC practitioners. In 1996, an article appeared reporting on “sophisticated separation methods and the oil industry”, with the authors declaring that the “instrumentation required for GC×GC is beautifully simple and potentially inexpensive” (11). Such a statement, in itself related to the instrumentation initially developed by J.B. Phillips and collaborators, is certainly agreeable (1,9,10).

Recent Application and Instrumental Trends

As mentioned earlier, recent application and instrumental trends will relate to the combined period 2018 to 2019. To obtain such information, a search process was launched by using the Scopus database and the keywords: “comprehensive twoâdimensional gas chromatography”. The database provided a list of 136 papers for 2018 and 121 papers for 2019. It is obvious that, even though some published data were most probably missed, a total number of 257 works do give an overall view on the current situation. It is noteworthy that a recent review entitled: “Comprehensive two-dimensional gas chromatography advances in technology and applications: biennial update” has been published (5). Overlap of the information herein provided with respect to that work will try to be avoided, while particular attention will be devoted to the fact that the concept of GC×GC is inherently simple.

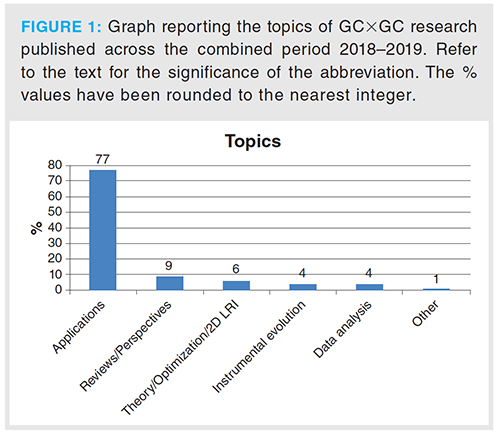

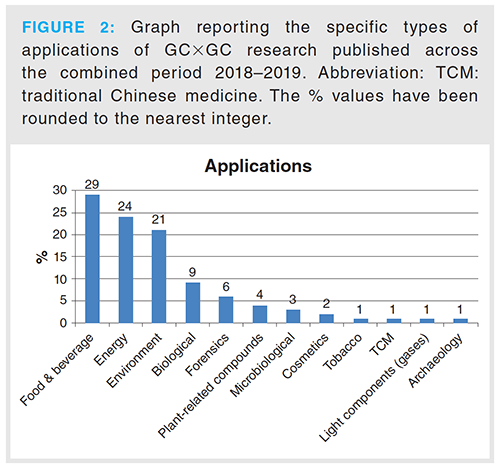

With regard to the topics, a main one was defined for each publication, with a clear dominance of application research observed (77%), followed by reviews and perspectives (9%) (Figure 1). Among the applications (Figure 2), food and beverage (29%), energy (24%), environment (21%), and biological (9%) occupy the first four positions, with the first three being by far the most popular. With regard to reviews and perspectives, these involve manuscripts covering both a specific GC×GC aspect or application (for example, metabolomics [12], modulation [13], environment [14]) and those describing GC×GC as an option within a specific research field (for example, analysis of S-containing compounds in petroleum [15], solid-phase microextraction [SPME] [16]). Considering the sum of application research and reviews and perspectives, these represent 86% of the published work across the period 2018–2019. A third topic relates to theory and optimization (for example, retention time prediction [17], FM model [18], solid-state modulation optimization [19]) and 2D linear retention index (LRI) calculation (20,21), represented by 6% of the published works. With regard to instrumental evolution and data analysis, these were characterized by only 4% each of the published work. Technological advances have involved, among others, a miniaturized GC×GC system (22), the use of a microâreactor prior to FID detection (23), a silver-based ionic liquid 2D column (24), and different FM approaches (25,26).

Proceeding onto the utilization of modulation approaches, specific information was attained from the majority of the 257 publications (for some papers we had access only to the abstract). As expected, CM was by far the most common choice (87%), followed by FM (10%), and solid-state modulation (3%).

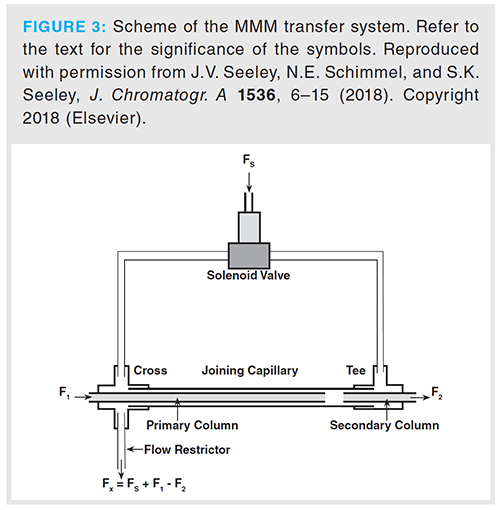

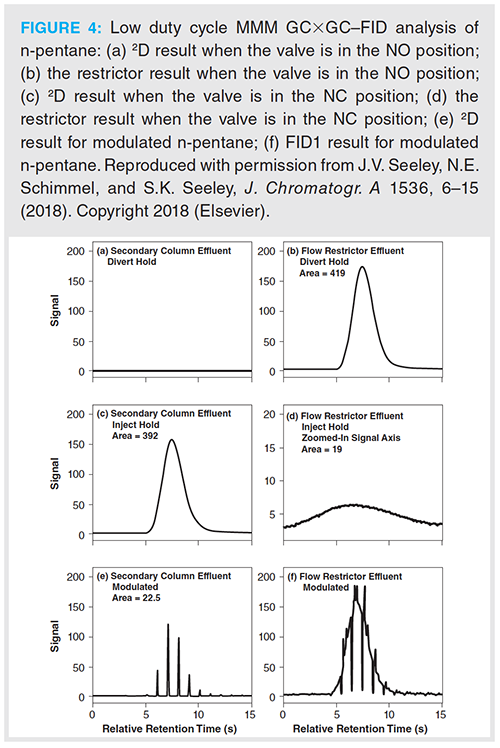

Focus is herein devoted to FM, which is an area that has undergone evolution in recent years. For example, in 2018 Seeley et al. introduced a novel system based on the Deans switch principle and defined multi-mode modulator (MMM) (25). A scheme of the MMM GC×GC system is shown in Figure 3. As can be observed, the MMM is of simple construction and is characterized by a deactivated metal joining capillary, connected on the 1D side to a cross union and to a tee union on the 2D side. The tips of the 1D and 2D columns are fixed near to one another within the joining capillary. Two metal capillaries link the unions to a solenoid valve (the normally opened [NO] port of the solenoid valve is connected to the tee union), which in turn receives a gas flow (FS) from a pneumatic control module. The fourth port of the cross union is linked to an FID-connected restrictor (FID1). There are two flows entering the modulator, FS and F1 (1D flow), and two flows exiting it, FX (restrictor flow) and F2 (2D flow). When the valve is in the NO position, the 1D flow is directed to the restrictor (low duty cycle) or stored in the joining capillary (high duty cycle); when the valve is in the normally closed (NC) position, effluent from the 1D column is directed to the second one, and then subjected to FID monitoring (FID2). Depending on the gas flows involved, and on the proximity of the 1D and 2D column tips within the joining capillary, the MMM could be operated as a low or high duty cycle modulator (consult reference 25 for more information). Under low duty cycle conditions, a 6% cyanopropyl phenyl + 94% polydimethylsiloxane 30 m × 0.25 mm, 1.4-μm df column was used in the first dimension (flow: 1.0 mL/min), and a polyethylene glycol 0.5 m × 0.18 mm, 0.18-μm df column in the second (flow: 0.9 mL/min). The modulation period was 1000 ms with a 75 ms injection time, meaning that only a low percentage of the 1D effluent reached the 2D. A nice example on the various effects of a low duty cycle MMM process on a highly volatile compound (n-pentane) can be observed in Figure 4(a–f): the FID2 result when the valve is in the NO position is shown in (a), highlighting the fact that no effluent from the first dimension reaches the second; the FID1 result when the valve is in the NO position is shown in (b); the FID2 result when the valve is in the NC position (transfer mode) is shown in (c); the FID1 result when the valve is in the NC position is shown in (d), highlighting the fact that a small amount of effluent from the first dimension reaches the restrictor; the effects of modulation on n-pentane are shown in (e) (FID2 result) and in (f) (FID1 result). Very narrow peak widths at half height were reported for modulated n-octane (53 ms). Such MMM conditions were characterized by a duty cycle of 0.054 (ratio of the total area of the modulated pulses to that of the unmodulated peak), and were suitable for highâspeed separations on short segments of micro-bore (≤ 0.18 mm internal diameter [i.d.]) column, and for MS detection (if used).

Under high duty cycle conditions, an apolar 40 m × 0.18 mm, 0.18-μm df column was used in the first dimension (flow: 0.50 mL/min), and a polyethylene glycol 5 m × 0.25 mm, 0.25-μm df column in the second (flow: 10.0 mL/ min). The modulation period was 1500 ms, with a 150 ms injection time. A fuel sample was subjected to analysis with peak widths at half height of approximately 80 ms. Such MMM conditions were characterized by a duty cycle of 1, and were suitable for high-speed separations on medium-length (5–8 m) segments of columns with an i.d. ≥ 0.25 mm. A flow of 10.0 mL/min can be considered as rather high for mass spectrometry, and possibly requires splitting prior to the ion source depending on the MS system used.

The 100% transfer FM approach described in reference 26 is characterized by increased simplicity (compared to reference 25): a six-port valve modulator (without a sample loop) was used, with connections (in an anticlockwise manner) to the injector, to the inlet and outlet of the 1D, to the inlet of the 2D, and to an additional gas source (the sixth port was blocked). Different samples were subjected to FM GC×GC–FID analyses under a variety of operational conditions: for example, a sample of diesel was subjected to a 1D separation on an apolar 15 m × 0.25 mm, 0.25-μm df column, and a 2D separation on a polyethylene glycol 5 m × 0.25 mm, 0.25-μm df column. The flow rates were 10 mL/min during the transfer process (0.4 s) and 30 mL/min for the remaining part of the separation on the 2D (14.6 s). During the analysis, the valve was maintained at a temperature of 300 °C. It is noteworthy that during the main part of the modulation period (14.6 s), there was a condition of stop-flow in the 1D, leading to an increase in the analysis time but also to a nonâinterdependence between the 1D and 2D separations. In general, the reported 2D gas flows were rather high (≥ 10.0 mL/min).

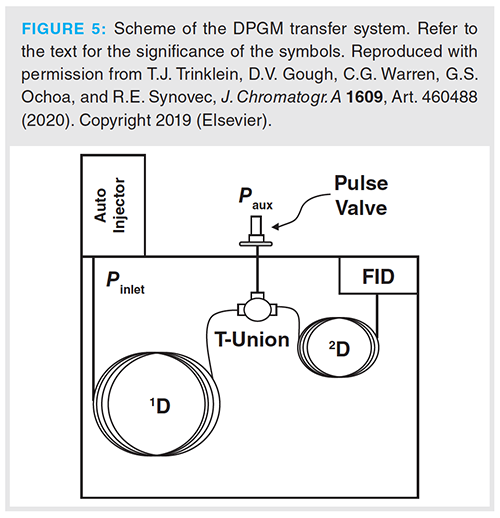

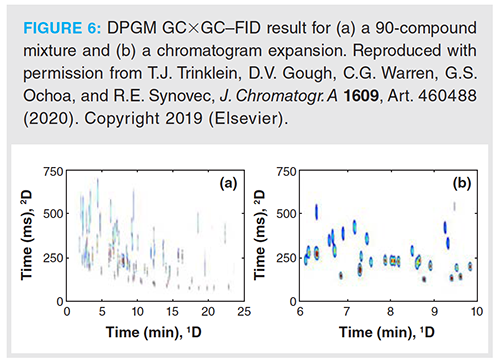

An even more simple FM approach of high interest (defined dynamic pressure gradient modulation [DPGM]) was described by Trinklein et al. at the beginning of 2020 (27): the 1D and 2D columns were linked through a tee union and connected to a pulse valve (Figure 5). An auxiliary gas source fed the valve (Paux). Under suitable conditions of injector pressure (Pinlet), Paux (both inlet and auxiliary pressures are ramped during the analysis), and valve open and close times, a 100% transfer GC×GC analysis could be achieved. When the valve was closed a fraction of the 1D effluent was transferred onto the 2D, while when it was opened, 1D elution was interrupted (stop flow) and the 2D separation proceeded. For example, a 90-compound mixture was subjected to a DPGM GC×GC–FID analysis by using an apolar 10 m × 0.18 mm, 0.18-μm df 1D column, and a polar 1 m × 0.18 mm, 0.10-μm df 2D column. The modulation period was only 750 ms, with a 60 ms valve close time. The applied Paux generated a 2D gas flow of 22.9 mL/min at the beginning of the analysis. Peak widths were narrow in time and variable, being in the range 20–180 ms (Figure 6). In a further DPGM GC×GC–FID analysis on diesel fuel, the use of a longer 2D column (2 m × 0.18 mm, 0.18-μm df) enabled the reduction of the 2D flow to 8 mL/min. In this instance, a modulation period of 2000 ms with a 150 ms valve close time was used. Very recently, DPGM GC×GC was combined with low-resolution time-of-flight (LR TOF)-MS, using a 2D gas flow of 4 mL/min (28).

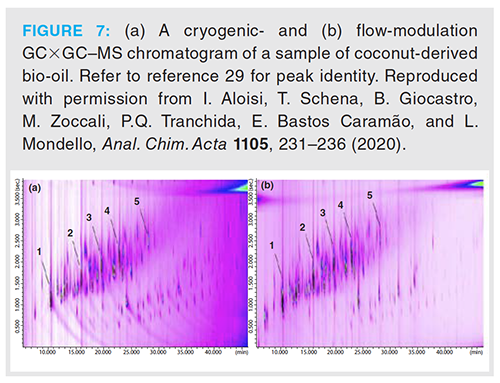

A major concern when using FM is the lack of analyte band compression; this is a typical feature of CM leading to very high peak capacities. It was within such a context that Aloisi et al. attempted to determine an equivalent standard column set between CM and FM GC×GC–MS (29). Cryogenic modulation was performed by using a loop-type system, while FM was performed by using a seven-port wafer chip equipped with an external sample loop and was a 100% transfer device (29). Very similar chromatography performances were attained when using an apolar 30 m × 0.25 mm, 0.25-μm df + polar 1.5 m × 0.25 mm, 0.25-μm df CM column set and an apolar 20 m × 0.18 mm, 0.18-μm df + polar 5 m × 0.32 mm, 0.25-μm df FM set (obviously the same types of stationary phases were used). The CM and FM results, attained on a sample of coconut bio-oil, are shown in Figure 7. This study provided an idea of the potential of the FM approach used compared with CM.

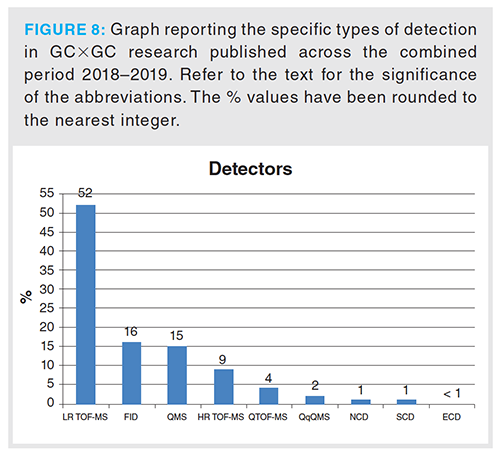

Considering detection (again, specific information was attained from the majority of the publications, not from all), obviously mass spectrometry confirms its dominant role (Figure 8). The first four positions are occupied by LR TOFâMS (52%), FID (16%), single quadrupole (Q)MS (15%), and highâresolution (HR) TOF-MS (9%). The use of both LR TOFâMS and rapid-scanning QMS are now well-established. With regards to HR TOF-MS, the definition of “high resolution” is rather vague. A powerful HR TOF-MS system used in the GC×GC field is capable of exceeding a resolution of 25,000 (full width half maximum [fwhm]), operating with a normal GC mass range and a high acquisition frequency (200 Hz) (30). Even though there has been an increasing use of QTOFâMS, it should be noted that its MS/MS capabilities are usually not exploited. In fact, the quadrupole is normally operated as a flyâthrough zone, with high-resolution mass spectra generated by the TOF analyzer. For example, Bowman et al. used GC×GC–QTOFâMS with atmospheric-pressure chemical ionization (APCI) in an environmental study involving the Athabasca oil sands (31). The mass spectrometer was operated in the TOF mode, at a resolution of 20,000 (fwhm) and at an acquisition frequency of 30 Hz. If one sums up the use of HR TOF-MS and QTOF-MS during the period 2018–2019, then HR MS is used at a similar level with respect to QMS. Considering ionization processes, electron ionization (EI) is by far the most popular approach. The use of soft forms of ionization, such as APCI (31), is reported rather rarely. The use of an LR TOF-MS system with the capability to perform hard (70 eV) and soft (14 eV) EI, in a rapid alternate manner and with a satisfactory analytical response, has started to appear (32). The use of triple quadrupole (QqQ) MS was found in only 2% of the published research. Such a trend can be related to the targeted nature of QqQMS analyses, whereas the power of GC×GC stands out in untargeted analyses. However, the use of QqQMS, with the capability to generate both untargeted (scan) and targeted (multiple reaction monitoring) data in a rapid alternate manner, has been reported (33).

The use of FID has declined greatly and is now comparable to that of QMS. Forms of selective detection, such as nitrogen and sulphur chemiluminescence detection (NCD, SCD), and electron capture detection (ECD), find little current use (Figure 8). In the authors’ opinion, among several reasons for such a trend is the fact that GC×GC separations are generally characterized by many more peaks compared to conventional GC ones, increasing the need for mass spectrometry.

Future Prospects

Comprehensive 2D-GC is becoming a mature technology, as can be concluded by observing recent literature, which is dominated by application research and with less space devoted to technological evolution. Such a tendency will probably continue, also in part as a result of the continuous evolution of MS. In fact, the availability of (powerful) MS reduces the requirements of an improved separation performance on the GC×GC side.

What are the future prospects of GC×GC? There will probably be an increasing development of smaller, less-energy consuming GC×GC(–MS) devices. It is anticipated that modulation will be part of such a downscaling, involving the use of robust, compact, simple, and effective devices. Modulation approaches that could potentially fit such a description are present both in past (1,10) and in present research (25–29).

References

- Z. Liu and J.B. Phillips, J. Chromatogr. Sci.29, 227–231 (1991).

- J.B. Phillips and J. Beens, J. Chromatogr. A856, 331–347 (1999).

- M. Adahchour, J. Beens, and U.A.Th. Brinkman, J. Chromatogr. A1186, 67–108 (2008).

- J.V. Seeley and S.K. Seeley, Anal. Chem.85, 557–578 (2013).

- M.S.S. Amaral, Y. Nolvachai, and P.J. Marriott, Anal. Chem.92, 85–104 (2020).

- R.M. Kinghorn and P.J. Marriott, J. High Resol. Chromatogr.21, 620–622 (1998).

- C.A. Bruckner, B.J. Prazen, and R.E. Synovec, Anal. Chem.70, 2796–2804 (1998).

- J-M. Dimandja, Am. Lab. 35, 42–53 (2003).

- J.B. Phillips and J. Xu, J. Chromatogr. A703, 327–334 (1995).

- Z. Liu and J.B. Phillips, J. Microcol. Sep.6, 229–235 (1994).

- P. Schoenmakers, J. Blomberg, and S. Kerkvilet, LCGC International14, 718–724 (1996).

- E.A. Higgins Keppler, C.L. Jenkins, T.J. Davis, and H.D. Bean, TrAC, Trends Anal. Chem.109, 275–286 (2018).

- H.D. Bahaghighat, C.E. Freye, and R.E. Synovec, TrAC, Trends Anal. Chem.113, 379–391 (2019).

- A.M. Muscalu and T. Górecki, TrAC, Trends Anal. Chem.106, 225–245 (2018).

- Y. Han, Y. Zhang, C. Xu, and C.S. Hsu, Fuel221, 144–158 (2018).

- S. Huang, G. Chen, N. Ye, X. Kou, F. Zhu, J. Shen, and G. Ouyang, Anal. Chim. Acta1077, 67–86 (2019).

- R. Jaramillo and F.L. Dorman, J. Chromatogr. A1581–1582, 116–124 (2018).

- M. Giardina, J.D. McCurry, P. Cardineal, G. Semard-Jousset, C. Cordero, and C. Bicchi, J. Chromatogr. A1577, 72–81 (2018).

- M. Zoccali, B. Giocastro, P.Q. Tranchida, and L. Mondello, J. Sep. Sci.42, 691–697 (2019).

- M. Jiang, Anal. Chem.91, 4085–4091 (2019).

- D.M. Mazur, I.G. Zenkevich, V.B. Artaev, O.V. Polyakova, and A.T. Lebedev, J. Chromatogr. A1569, 178–185 (2018).

- J.J. Whiting, E. Myers, R.P. Manginell, M.W. Moorman, J. Anderson, C.S. Fix, C. Washburn, A. Staton, D. Porter, D. Graf, D.R. Wheeler, S. Howell, J. Richards, H. Monteith, K.E. Achyuthan, M. Roukes, and R.J. Simonson, Lab Chip19, 1633–1643 (2019).

- J. Luong, Y. Hua, R. Gras, and R.A. Shellie, Anal. Chem.91, 11223–11230 (2019).

- I.D. Souza, H. Nan, M.E.C. Queiroz, and J.L. Anderson, Anal. Chem.91, 4969–4974 (2019).

- J.V. Seeley, N.E. Schimmel, and S.K. Seeley, J. Chromatogr. A1536, 6–15 (2018).

- H. Cai and S.D. Stearns, J. Chromatogr. A1569, 200–211 (2018).

- T.J. Trinklein, D.V. Gough, C.G. Warren, G.S. Ochoa, and R.E. Synovec, J. Chromatogr. A1609, Art. 460488 (2020).

- S. Schöneich, D.V. Gough, T.J. Trinklein, and R.E. Synovec, J. Chromatogr. A In press DOI: 10.1016/j.chroma.2020.460982.

- I. Aloisi, T. Schena, B. Giocastro, M. Zoccali, P.Q. Tranchida, E. Bastos Caramão, and L. Mondello, Anal. Chim. Acta1105, 231–236 (2020).

- B. Savareear, J. Escobar-Arnanz, M. Brokl, M.J. Saxton, C. Wright, C. Liu, and J.-F. Focant, J. Chromatogr. A1581–1582, 105–115 (2018).

- D.T. Bowman, K.J. Jobst, X. Ortiz, E.J. Reiner, L.A. Warren, B.E. McCarry, and G.F. Slater, J. Chromatogr. A1536, 88–95 (2018).

- E. Omar, E. Bichon, S. Hutinet, A.-L. Royer, F. Monteau, H. Germon, P. Hill, G. Remaud, G. Dervilly-Pinel, R. Cariou, and B. Le Bizec, J. Chromatogr. A1601, 327–334 (2019).

- M. Zoccali, S. Cappello, and L. Mondello, J. Chromatogr. A1547, 99–106 (2018).

Peter Q. Tranchida is Associate Professor in food chemistry in the Department of Chemistry, Biological, Pharmaceutical and Environmental Sciences at the University of Messina, in Italy. His research activities are focused mainly on the study of complex food samples by using advanced chromatography processes. In particular, he has performed a great deal of research work in the field of classical multidimensional gas chromatography, multidimensional liquidÐgas chromatography, and comprehensive 2D-gas chromatography (GC×GC).

Ivan Aloisi received his master’s degree in pharmaceutical chemistry and technology in 2017 (University of Messina), discussing a thesis entitled “Qualitative analysis of the unsaponifiable fraction of vegetable oils using comprehensive two-dimensional gas chromatography coupled with high resolution mass spectrometry”. He is now Ph.D. student in chemical sciences in the University of Messina.

Luigi Mondello is Full Professor of Analytical Chemistry at the University of Messina. His research is focused on the development of multidimensional chromatographic instrumentation and software, coupled to state-of-the-art MS, for the study of complex matrices constituents and contaminants. He is the author of around 500 scientific papers and 1000 conference presentations, with an H-index of 64 (Google Scholar) and a total impact factor of more than 1000. He has been awarded with the HTC Award, COLACRO Medal, Silver Jubilee Medal, Liberti Medal, TASIAs, IFEAT Medal, GC×GC Lifetime Achievement, Golay Award, Robert Kellner Lecture, and the Herbert J. Dutton Award.

New Study Reviews Chromatography Methods for Flavonoid Analysis

April 21st 2025Flavonoids are widely used metabolites that carry out various functions in different industries, such as food and cosmetics. Detecting, separating, and quantifying them in fruit species can be a complicated process.

University of Rouen-Normandy Scientists Explore Eco-Friendly Sampling Approach for GC-HRMS

April 17th 2025Root exudates—substances secreted by living plant roots—are challenging to sample, as they are typically extracted using artificial devices and can vary widely in both quantity and composition across plant species.

Sorbonne Researchers Develop Miniaturized GC Detector for VOC Analysis

April 16th 2025A team of scientists from the Paris university developed and optimized MAVERIC, a miniaturized and autonomous gas chromatography (GC) system coupled to a nano-gravimetric detector (NGD) based on a NEMS (nano-electromechanical-system) resonator.

Miniaturized GC–MS Method for BVOC Analysis of Spanish Trees

April 16th 2025University of Valladolid scientists used a miniaturized method for analyzing biogenic volatile organic compounds (BVOCs) emitted by tree species, using headspace solid-phase microextraction coupled with gas chromatography and quadrupole time-of-flight mass spectrometry (HS-SPME-GC–QTOF-MS) has been developed.