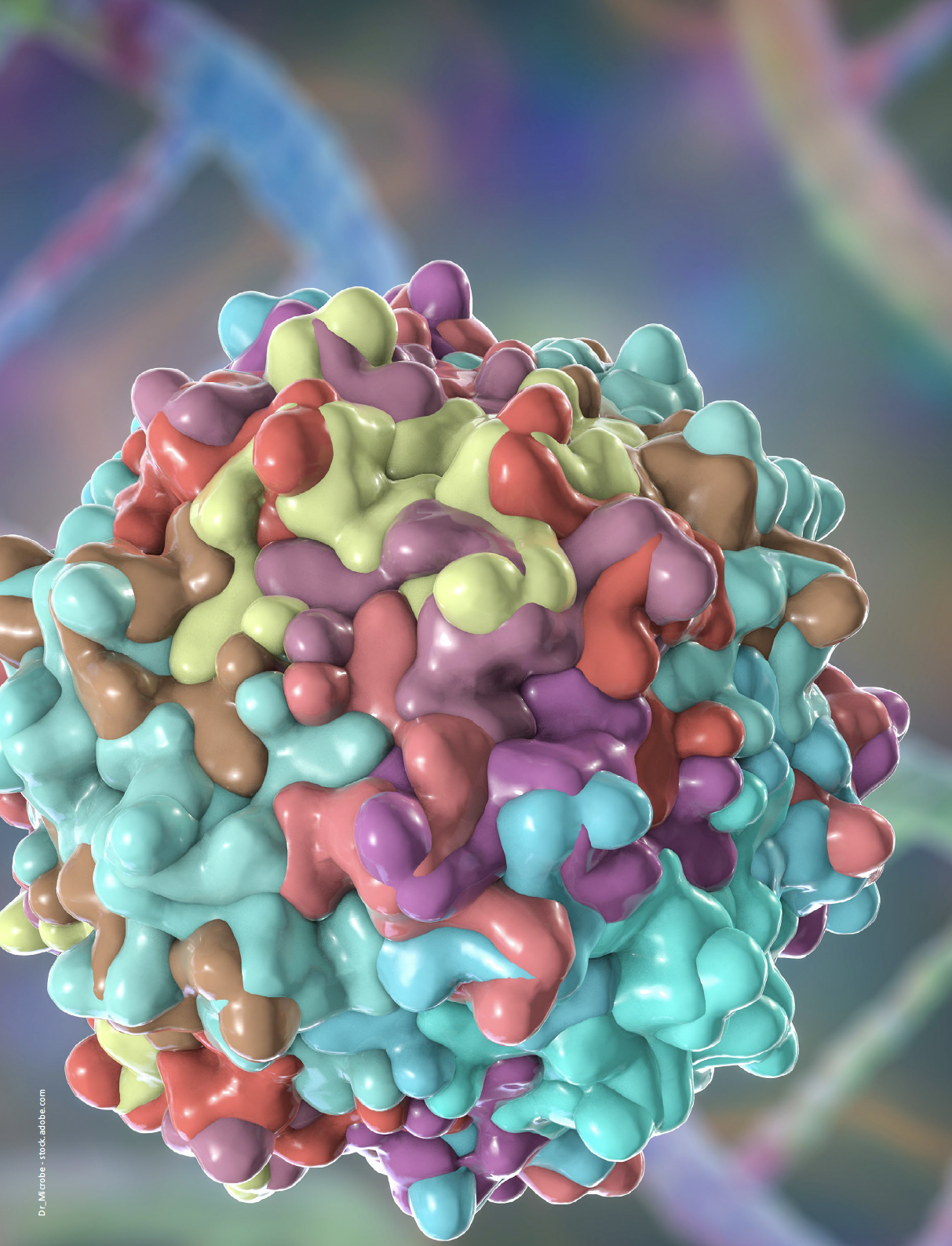

Rapid Method to Characterize Adeno-Associated Virus (AAV) Therapies Using SEC–FLD

Adeno-associated virus (AAV) gene therapies have created analytical challenges for drug developers. Current technologies and consumables are not well-suited for the already low sample volume used to determine the critical quality attributes (CQAs) of AAVs. Stationary phases with novel pore and column dimensions and inert particle chemistry demonstrate increased efficiencies and robustness for AAV analysis. These advances can enable researchers to make critical analytical decisions with confidence and ultimately, ensure drug time-to-market.

The rapid growth of AAV gene-based therapies is catalyzed by several factors such as AAVs’ wide range of tropism for increased personalized medicine efficacies and their ability to carry large amounts of genome (the drug) to ensure dosing optimization. Currently, there are more than 235 AAV therapies in various clinical trial phases, and twelve AAV-based therapies have been approved since 2012. The global market for AAVs, currently estimated to be worth more than $767.7 million, is expected to expand at a compound annual growth rate of 22.5% through 2030 (1).

With this growth comes significant challenges to ensure the viral vectors’ efficiencies throughout the drug development stages. Common chromatographic methods used for established modalities such as monoclonal antibodies (mAbs) are applicable to analyzing AAVs. The problem is that the manufacturing scale of viral vectors is a lot smaller than it is for mAbs. The AAV preclinical manufacturing sizes range from hundreds of microliters to 50 L, while mAb production volumes have typically been over 500 L. Some consumables are not currently optimized to handle smaller volumes. Therefore, there is an unmet need to support the analytical challenges of this small-volume, advanced therapeutics industry.

The good news is that chromatographic consumables and solutions are rapidly evolving to address these unmet needs while maintaining, or even increasing, data quality. Coupled with existing instrumentation, these different approaches enable the analysis of multiple AAV critical quality attributes (CQAs), which help to mitigate sample consumption. These approaches ultimately increase AAV drug development efficiencies and ensure time-to-market.

Improving Aggregate Analysis

The most intense and high volume of analysis occurs during the AAV characterization stages. Early comprehension of the vector’s CQAs is critical for drug candidate selection as well as for process and formulation development and optimization. Robust and reliable analytical methods used to characterize AAVs are therefore required. The importance of robustness and reliability of these methods is even further emphasized when “fit-for-purpose” consumables are used.

An essential CQA of AAVs is aggregate identification and quantification. Aggregation can cause AAV-based therapeutics to lose efficacy or impact immunogenicity, which negatively impacts drug and patient safety. Aggregation is often driven by suboptimal processing, formulation, and storage conditions.

The gold standard for AAV aggregate analysis has long been analytical ultracentrifugation (AUC). However, AUC requires sample sizes up to 400 mL, takes an average 90 min of run time to complete, and has a high learning curve.

Size-exclusion chromatography (SEC) is recognized as an orthogonal method to AUC and is more efficient. On average, AAV aggregate analysis with SEC consumes only about 20 μL of sample, and analysis for one sample can be completed in as little as 14 min. But this is still not ideal. Researchers are seeking to achieve faster turnaround times for analysis while consuming even less sample volume—all without compromising data quality.

Current SEC technology research is proving that an inert, 700 Å pore size particle provides robust and reliable baseline separation between monomer and aggregate, as well as better peak identification between aggregates. Coupled with smaller inner diameters, an SEC column with these dimensions holistically mitigates high sample consumption without sacrificing data analysis efficiency and quality of AAV aggregate analysis.

Demonstrating an Optimized SEC Column for AAV Analysis

Research was performed in 2023 on AAV serotypes 1, 2, 3, 4, 5, 6, 8, 9 and rh10 using a Biozen 3 μm dSEC-7 (Phenomenex). Two column dimensions were tested: 150 × 4.6 mm and 300 × 4.6 mm. For AAV8-CMV-GFP, five samples at concentrations ranging from 2×1011 viral genomes per mL (vg/mL) to 2×1012 vg/mL were prepared in 0.2 μm filtered 1x phosphate buffered saline with 0.001% Pluronics F68 into HPLC vials. For serotype AAV studies on the 300 × 4.6 mm column format, separate dilutions of 4×1011 vg/mL were prepared and centrifuged at 10,000 relative centrifugal field for 5 min prior to injection on the LC system (Agilent 1260 Infinity with Agilent FLD and UV).

Results and Discussion

The study demonstrated that the SEC technology produced highly reproducible peak areas, retention time, and percentage monomer. The running pressures for the 150 × 4.6 mm and 300 × 4.6 mm columns at a flow rate of 0.5 mL/min were 78 and 155 bars, respectively. These running pressures combined with the achievable resolution demonstrated that a suitable particle size was chosen.

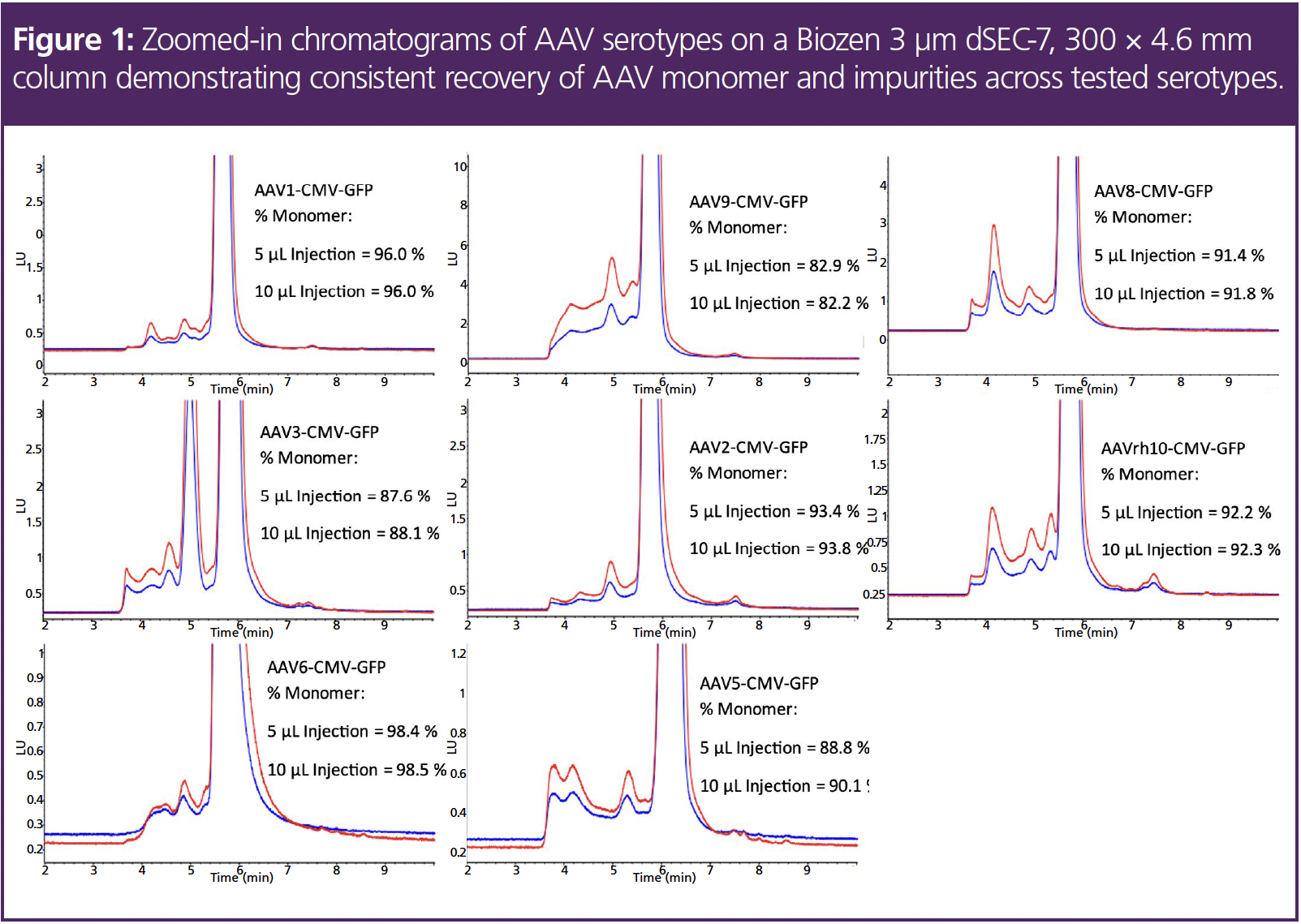

The column was found to be suitable for separating the monomer from its aggregates and impurities for serotypes 1, 2, 3, 5, 6, 8, 9 and rh10 with a 5-microliter injection volume. Different serotypes displayed different retention times (Figure 1). Resolution between monomer and aggregate remained consistent when the volume was increased to 10 μL Therefore, doubling the viral load on the 300 × 4.6 mm column did not affect the percentage of monomer recovery determination. It is possible that even higher resolution separations could be achieved using a 300 × 4.6 mm format and a flow rate of 0.25 mL/min.

The study also demonstrated that the SEC column could be used to examine the effects of forced degradation on AAVs. Upon exposing AAV1 to heat, two new hydrodynamically larger species were formed. With continued heat exposure, the smaller species decreased, resulting in more of the largest species.

Conclusion

The analytical capabilities of SEC columns specifically designed for AAVs have been demonstrated. This technology, with its optimized column and pore sizes, promotes reproducible separations and recoveries for various AAV serotypes. An SEC method coupled with a fluorescence detector (FLD) using a 150 × 4.6 mm column can be completed in 8 min at a flow rate of 0.5 mL/min per on a normal HPLC system. As a result of the reproducible analytical performance of this column, it could be used for stability studies to determine the purity and quantity of the monomer left in the solution. It can also enable the determination of the critical quality attributes in drug substances and drug products. Furthermore, it could be used to drive the development of other analytical methods such as AAV capid load and titer quantity as well as IgM aggregation.

Reference

(1) Adeno Associated Virus Vector Manufacturing Market Size, Share & Trends Analysis Report By Scale Of Operations (Clinical, Commercial), By Method, By Application, By Therapeutic Area, By Region, And Segment Forecasts, 2023 - 2030. Adeno Associated Virus Vector Manufacturing Market Report, 2030. Grand View Research, 2023. https://www.grandviewresearch.com/industry-analysis/adeno-associated-virus-vector-manufacturing-market-report (accessed 2024-03-04).

Tran Pham is a Global Market Development Manager for BioPharma at Phenomenex. She has more than 15 years of industry experience that encompasses analytical development, training, sales, and marketing. Email: tranp@phenomenex.com

Characterizing Plant Polysaccharides Using Size-Exclusion Chromatography

April 4th 2025With green chemistry becoming more standardized, Leena Pitkänen of Aalto University analyzed how useful size-exclusion chromatography (SEC) and asymmetric flow field-flow fractionation (AF4) could be in characterizing plant polysaccharides.

Rethinking Chromatography Workflows with AI and Machine Learning

April 1st 2025Interest in applying artificial intelligence (AI) and machine learning (ML) to chromatography is greater than ever. In this article, we discuss data-related barriers to accomplishing this goal and how rethinking chromatography data systems can overcome them.

Influence of Concentration in Conventional GPC/SEC and Advanced Detection GPC/SEC

March 21st 2025Sample concentration is a parameter that can influence the quality of gel permeation chromatography/size-exclusion chromatography (GPC/SEC) separations and the obtained results. Understanding this influence can help to support the development of reliable GPC/SEC methods.