Nanomaterials Have Come to Stay: An Overview of their Use as Sorbents in Sample Preparation

This article reviews how nanomaterials are being used in a variety of sample preparation techniques, such as dispersive solid-phase extraction (dSPE), solid-phase microextraction (SPME), stir-bar sorptive extraction (SBSE), and matrix solid-phase dispersion (MSPD).

Nanomaterials occupy an important place in current research and applications in analytical chemistry and, in particular, as extraction sorbents for sample preparation. Nanomaterials are useful as sample preparation sorbents as a result of their varied morphologies, high surface area, surface-to-volume ratio, and porosity, as well as their ability to interact in a variety of ways. The sorbent-based extraction procedure in which nanomaterials have been mostly commonly applied is dispersive solid-phase extraction (dSPE), but these materials also have been applied in other sample preparation techniques, such as solid-phase microextraction, stir-bar sorptive extraction, and matrix solid‑phase dispersion. Carbon-based nanomaterials are the most commonly used in sample preparation, but other types of materials used include metal–organic frameworks, covalent organic frameworks, nanoparticles combined or modified with other materials or nanomaterials, quantum dots, electrospun nanofibres, and dendrimers.

Judging from the high number of advances and applications of nanoscience and nanotechnology in recent years, it is clear that nanomaterials (structures with at least one dimension in the 1–100 nm range) have come to stay in our daily life, and, in particular, in the analytical chemistry laboratory. Some of these are nanomaterials themselves, whereas others can be suitably modified or combined to create nanomaterial units.

Sample preparation, the workhorse of analytical chemists, has found in nanomaterials an extraordinary ally, as a result of their varied morphologies, high surface area, surface-to-volume ratio, and porosity, as well as their ability to interact in a variety of ways. At the nanometer level, surface physics and chemistry start to dominate a material’s properties, which also depend on the material’s three-dimensional morphology, the surrounding media, and the material’s arrangement in space (1). Properly considered and managed, these properties can be of high utility. In particular, such properties are highly beneficial in sorbent‑based extraction procedures like solid‑phase extraction (SPE), solid‑phase microextraction (SPME), stir‑bar sorptive extraction (SBSE), membrane stir membrane (SME) , stir fabric phase sorptive extraction (SFPSE), and matrix solid‑phase dispersion (MSPD) (2,3), and, therefore, they have been applied mainly in such procedures for analyte enrichment or storage, sample fractioning, or cleanup, as well as support for derivatization reactions in nearly any type of sample matrix. Moreover, nanomaterial applications in sample preparation have also facilitated the development of miniaturized and more environmentally friendly procedures, which are key challenges and trends in analytical chemistry (4).

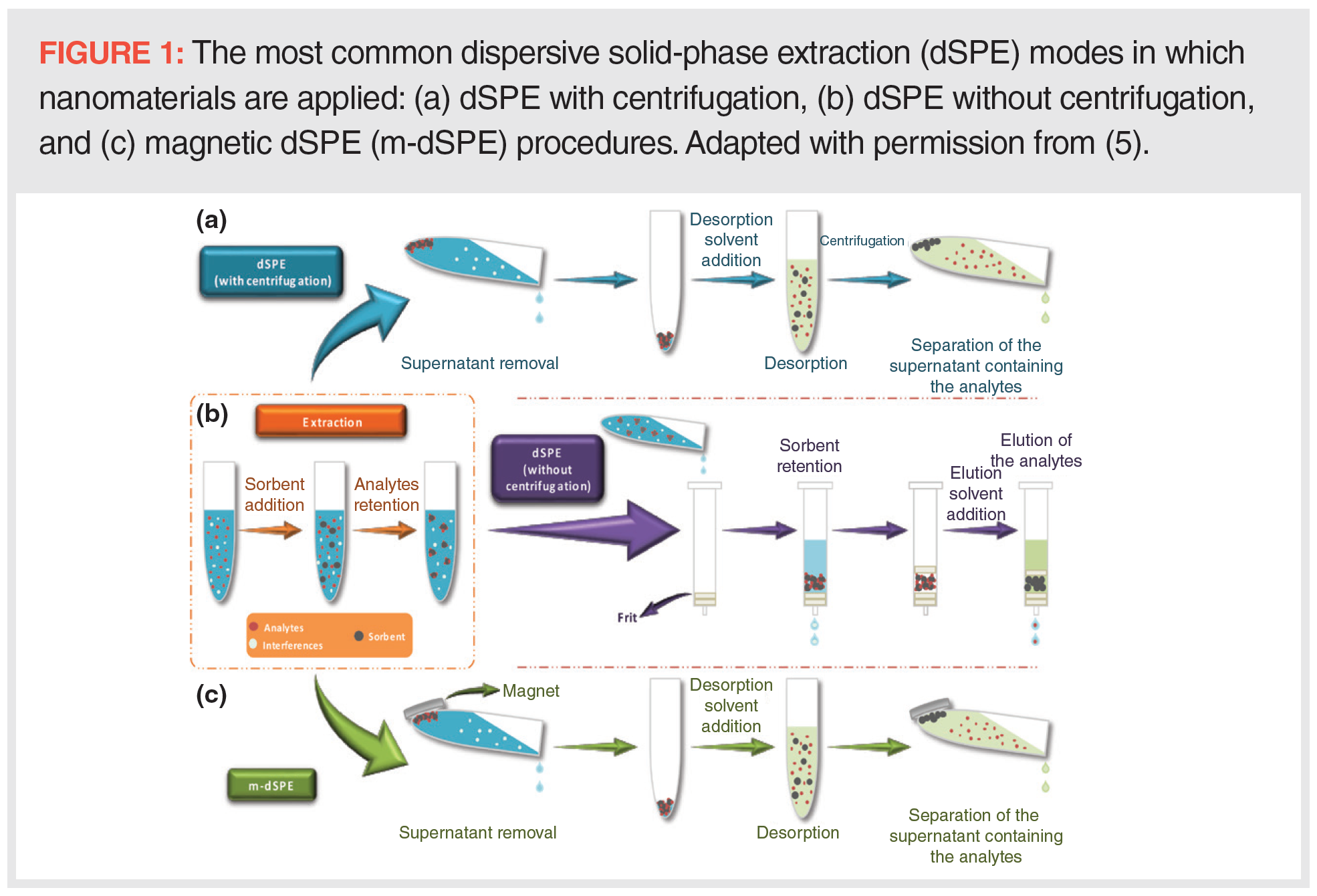

To date, the main use of nanomaterials in sorbent-based extraction methods has been in dispersive SPE (dSPE), in various operational modes, assisted by stirring, vortexing, or ultrasound procedures (Figure 1). With dSPE, the fact that bulk materials that quickly enter in contact with the sample or extract can be used, along with its simplicity and rapidity, has made dSPE an excellent choice for many applications. Of particular interest has been the application of magnetic sorbents, which were introduced in 1996 by Towler and colleagues (6), because the application of an external magnetic field considerably simplifies and facilities the procedures, saving time and effort. With SPE, in some cases nanomaterials have even been used in pipette-tip SPE (7), confined in small devices, bags, or disks that are inserted into the sample or extract, or in multiwell plates (8). As for SPME or SBSE coatings, when using nanomaterials, suitable, repeatable, and durable coating procedures must be achieved, which is not an easy task. For that purpose, physical adhesion, in-situ growth, or chemical bonding methods are used (9).

In general, the nanoscale materials that scientists are able to produce have some uncertainties and irregularities in their shape, size, and chemical composition. That fact has not limited their application as sorbents, however, because a certain degree of control over them can be ultimately achieved.

Carbon-Based Nanomaterials

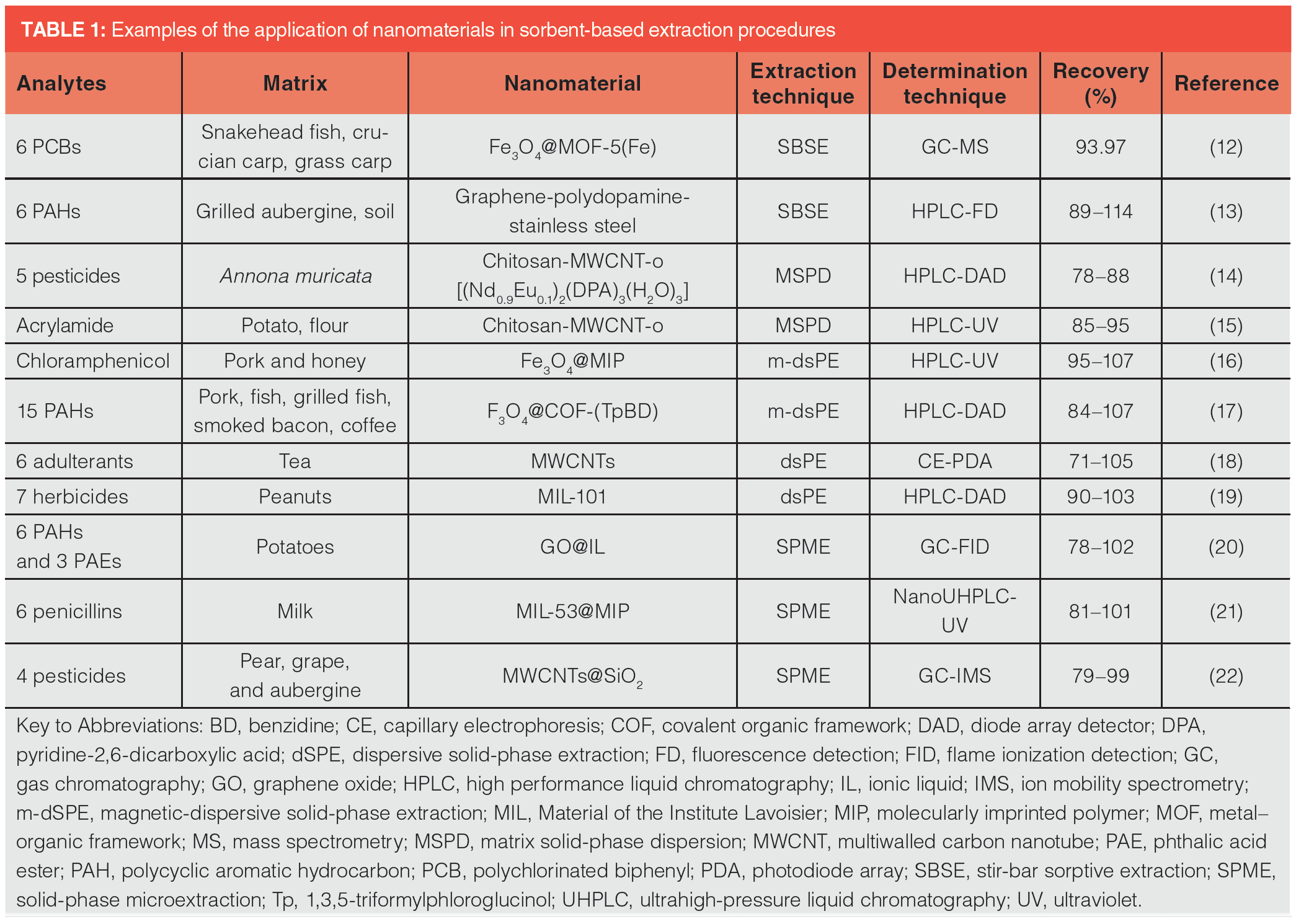

Carbon-based nanomaterials are one of the most extensively used types of nanomaterials applied to sample preparation. The reason for their extensive application probably lies in their ability to establish strong π-π interactions, because carbon‑based structures are composed of large conjugated π-systems, as well as Van der Waals interactions (as a result of fluctuating dipole moments caused by the distortion of the planar graphene sheet), in combination with their high stability, tensile strength, and so on, and the abovementioned typical features of nanomaterials. In this sense, pristine carbon-based nanomaterials have provided excellent results for the extraction of a wide variety of nonpolar organic compounds (10). The extraction of metals can also be achieved with pristine materials, though in that case, a prior complexation step is often necessary. On the other hand, polar compounds normally can be extracted using these nanomaterials, following a suitable functionalization (covalent or noncovalent) of the nanomaterial surface (11). Table 1 lists some research in which different nanomaterials, including carbon-based nanomaterials, have been applied as sorbents.

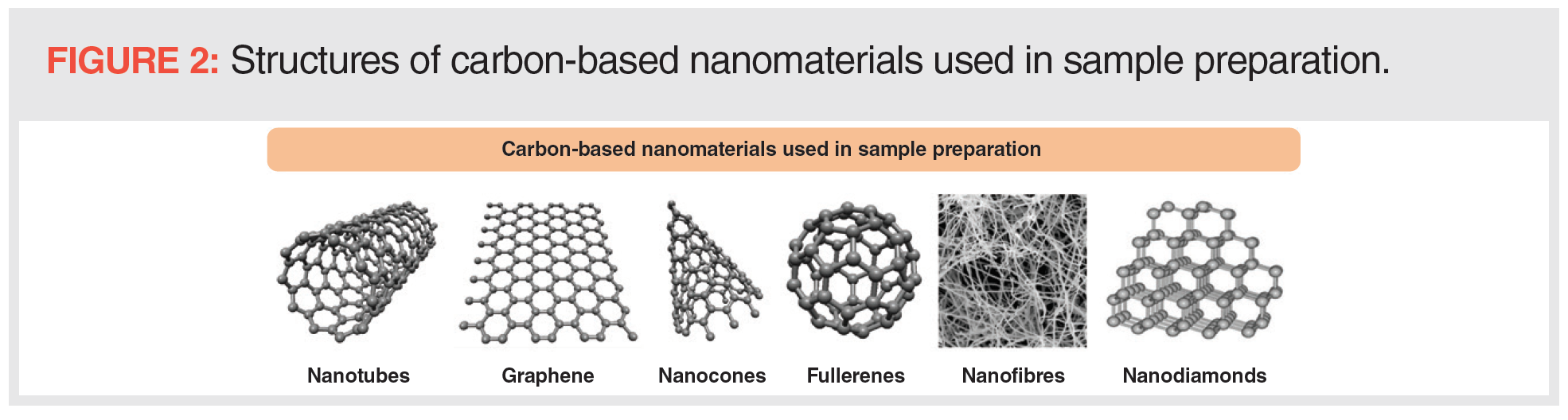

Among carbon-based nanomaterials, multiwalled carbon nanotubes (MWCNTs) and graphene are the two carbon allotropic forms most commonly used in sample preparation; in the first case, probably because they were the first to be synthesized and also the most commercialized. Others, such as single-walled carbon nanotubes (SWCNTs), fullerenes, carbon nanohorns, carbon nanofibres, and nanodiamonds (Figure 2) have also been used in this sense, though less frequently (23).

Although the application of pristine MWCNTs or graphene continues to have interest, current research is mainly focused on modifying their surface to increase their extraction selectivity and capacity, as well as to improve their solubility in many solvents, which is one of the main drawbacks for their application in extraction procedures. Thus, the particularities of their structures make it easy to modify them with molecules with aromatic systems (such as surfactants and polymers) by means of noncovalent interactions (11). However, covalently functionalized MWCNTs are now used more extensively, because of their simplicity and because a wide variety of molecules can be bound to the surface of these nanomaterials, generally starting by the simple oxidation of their sidewalls, which mainly introduces –COOH, –OH and – CO– groups into their structures (11,23).

Although graphene can be modified with molecules containing benzene rings, graphene oxide (GO) has become the most widely used way to functionalize this material; it is the most common method to obtain graphene based on the oxidation and exfoliation of graphite, which is also really cheap. In addition, carboxyl and hydroxyl groups present on the surface of graphene enable the binding of a wide variety of molecules, resulting in an important expansion of graphene’s applicability (22,24), though one of its main drawbacks is the fact that it is an ultralight material that is difficult to retrieve from a suspension, even by high-speed centrifugation.

In general, the great surface versatility of carbon-based nanomaterials is the main reason for their success in sample preparation, because it has allowed not only their use in all SPE modes, but also in the extraction of a broad spectrum of compounds, having been principally applied to the analysis of pesticides (10).

Lastly, it is important to mention that, despite the good features that carbon‑based nanomaterials have proven to have as sorbents, these materials also have been combined with other materials to provide them with other properties or to improve their selectivity. In this sense, as it will be later shown, their combination with magnetic nanoparticles (mNPs) has been the most common. However, they also have been combined with polymers, metal-organic frameworks (MOFs), or even other carbon-based nanomaterials, among others (2,3,9). At this point, it is important to highlight that such combinations should be properly justified, demonstrating that the extraction performance of the composite is better than that of the materials separately, which has not always been proven in the literature.

Metal–Organic Frameworks

MOFs are microporous inorganic–organic crystalline structures presenting a three‑dimensional and highly ordered structure (8) that when produced at extremely small sizes, can be considered and used as nanomaterials. Among current nanomaterials, MOFs have probably been the least explored in sample preparation, perhaps as a consequence of the high number of crystalline structures that can be created. However, it is precisely this fact that makes them so interesting as sorbents, because it makes it possible to control the features of the material. In addition, MOFs can boast being the nanomaterials with the largest surface area (from ~200 to ~7000 m2/g), as a result of their extremely high porosity. Finally, their capacity to be modified makes them almost the ideal sorbent to be used in SPE and dSPE procedures (8). In recent years, there also has been a noticeable increase in the number of studies in which MOFs have been used as SPME coatings (25), even more than other nanomaterials.

When working with MOFs, it is important to consider that these structures are not normally stable in solution, because their open metal sites are easily occupied by water, resulting in damage to the structure and a loss of extraction capacity (8,26). Thus, although bare MOFs have demonstrated a high extraction capacity, their post‑synthesis modification constitutes one of the main approaches to improve their hydrostability. Another common practice consists of the carbonization of the MOF structure to obtain an extremely porous carbon material that preserves the structure of the MOF used (though it is not a MOF itself). In some cases, it has been suggested that MOFs should be thermally activated before their use as sorbents to prevent solvent molecules from getting trapped in the MOF’s pores during synthesis (27). Combining MOFs with water‑repellent materials constitutes another alternative, though less frequently used (26). However, water-stable MOFs sometimes need to be functionalized, principally for three reasons: to reduce their hydrophobicity (to improve their contact with aqueous samples and to increase the adsorption of hydrophilic compounds); to enhance the selectivity of the nanomaterial; and to meet the demands of the extraction mode in which they are to be applied (26).

Like carbon-based nanomaterials, MOFs also have been combined with other materials to modify their extraction performance or to facilitate their separation from the sample. Once more, mNPs have been the material selected in most applications because of the advantages derived from their use. However, many combinations with carbon-based nanomaterials, polymers, or ionic liquids have also been developed (2,9).

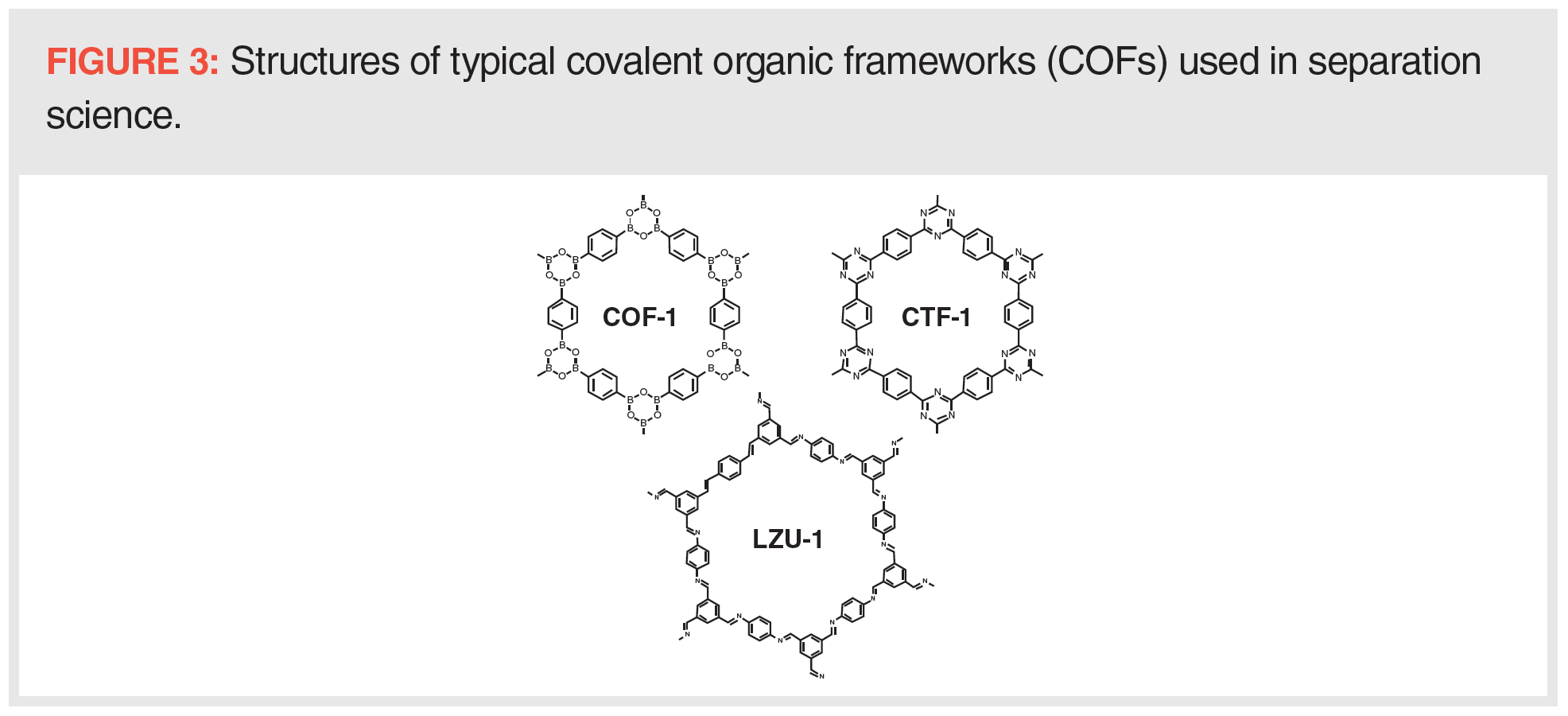

Covalent Organic Frameworks

Although MOFs have been demonstrated to be excellent sorbents for the extraction of a wide variety of molecules of different natures and sizes from a broad variety of matrices, during the last decade, covalent organic frameworks (COFs) have emerged as an alternative. COFs contain only light elements like H, B, C, N, O, and Si, providing an ordered crystalline organic polymeric structure via covalent bonds, but without metallic ions (28). They have good chemical and thermal stability, a tunable porous structure (though their porosity is not as high as that of MOFs), and low density (29). Their application as sorbents has been mainly carried out in SPME, though much less frequently than the rest of the materials discussed here. Figure 3 shows a schematic representation of typical COFs used in separation science.

Nanoparticles Combined or Modified with Other Materials or Nanomaterials

As previously indicated, since the introduction of magnetic SPE (mSPE) (6), mNPs have gained importance as sorbents in sample preparation procedures, because they provide clear advantages, such as a significant reduction of analysis time and an important simplification of the extraction procedure. The iron oxides magnetite (Fe3O4) and maghemite (γ-Fe2O3), especially the former, have been the mNPs most often used, principally because of their low toxicity, ease of manipulation and synthesis, and their ability to be modified, compared to other mNPs (30,31). Others composed of metals like iron, nickel, and cobalt, or their oxides, and spinel-type ferromagnets such as MnFe2O4, MgFe2O4, and CoFe2O4, have also been used.

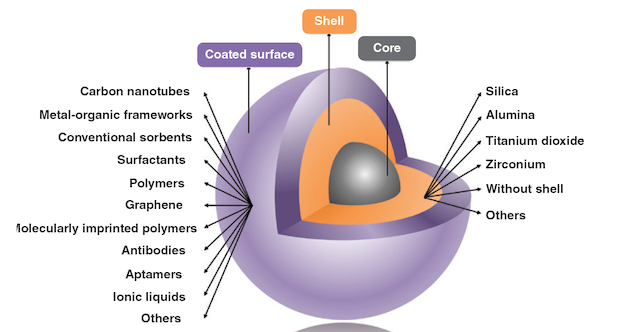

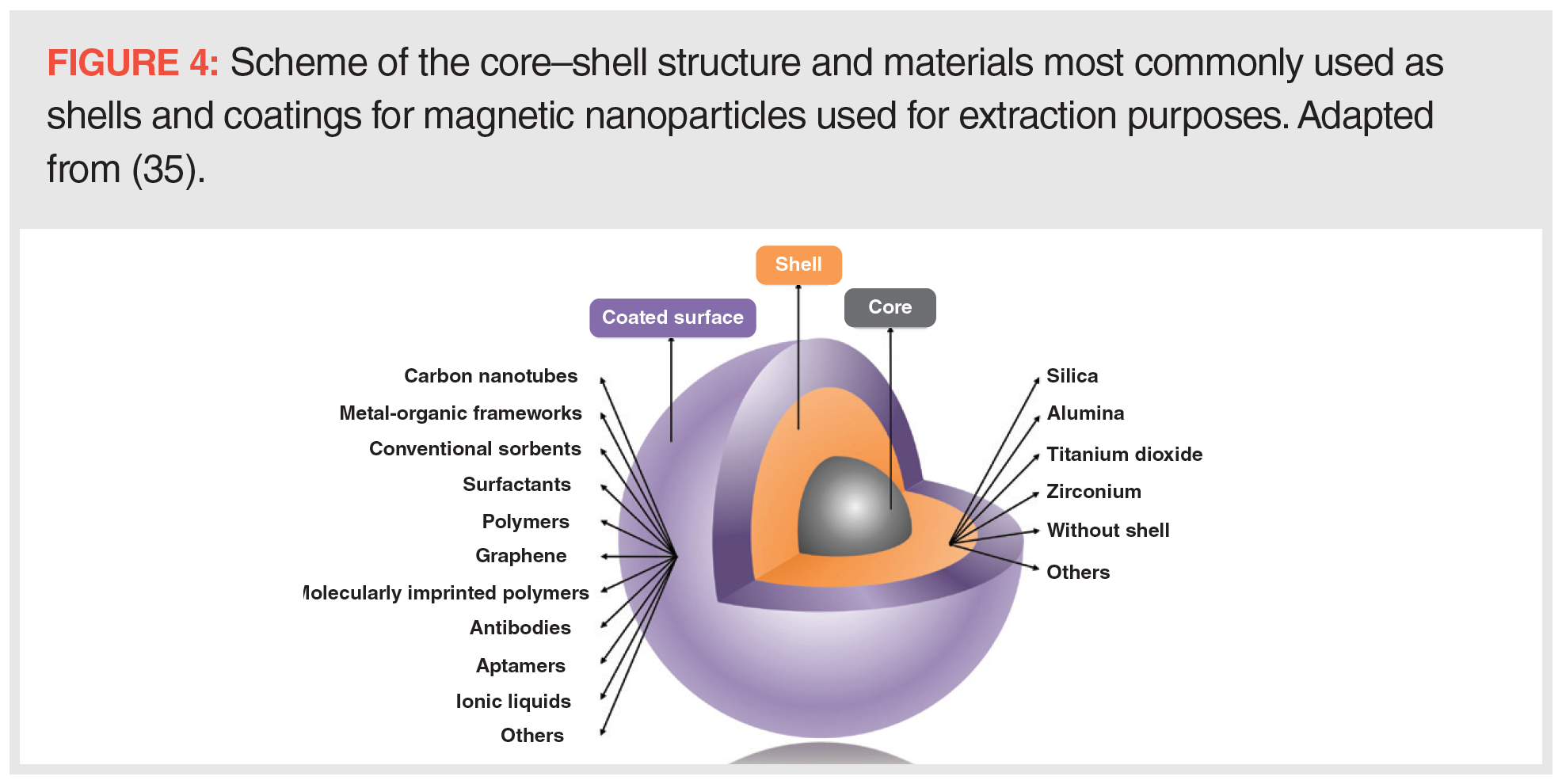

It should be noted that, although in certain applications this kind of mNP has been used as synthesized, without further modifications, they are only rarely used in analytical extraction methods, because of their high tendency to aggregation and their chemical reactivity, which results in a loss of dispensability (dispersibility) and magnetism (30). Trying to solve these problems, as well as to improve their selectivity and extraction capacity, the most common strategy consists of coating mNPs using different organic and inorganic materials, resulting in a core–shell structure (30,31) as shown in Figure 4. However, achieving a perfect core–shell structure is extremely difficult and rare.

Among the various inorganic materials that have been selected as coatings, silica is one of the most widely used, probably because of its stability and low price. However, an important factor that has favoured the extensive use of silica has been its numerous silanol groups, which can be easily modified with other functional groups, with octadecylsilane being the most common, though the most extended practice involves the use of the silica shell only as a support to attach other materials (30,31). On the other hand, the variety of organic coatings that has been used with this aim is much more extensive, including a good variety of surfactants, ionic liquids, antibodies, and aptamers, as some of the most common. Polymeric coatings (polymer-based nanosorbents) have been the most widely used by far, because they have demonstrated good stability and some of them can even bind directly to the surface of mNPs. Among them, molecularly imprinted polymers have become one of the preferred alternatives, as a consequence of their high selectivity and specificity (30,31).

The mNPs previously mentioned have been demonstrated to have a good surface-to-volume ratio, and provide a high extraction capacity in a wide number of applications. However, the trend in recent years has been to focus on combining mNPs with new sorbent materials, and especially nanomaterials, with the goal of combining the high adsorption capacity of nanomaterials and the separation convenience of magnetic materials (30). In this sense, the combination of mNPs with carbon-based materials, especially CNTs and graphene, has been one of the most extensive, as a result of their abovementioned excellent properties (2,3). Such combinations normally consist of the deposition of mNPs onto the surface of the carbonaceous materials, taking advantage of electrostatic forces. However, in certain applications using CNTs, the mNPs have been inserted inside the tubular structure (9). In addition, in recent years mNPs have been combined with several MOFs (Figure 5) (8) or COFs (29), providing excellent results. The synthesis procedures for these combinations are very diverse. Thus, carbon-based materials need to be first functionalized, while MOFs and COFs can be synthesized around the surface of the mNPs, though in some cases these materials can be combined using an ultrasound process (9).

As previously mentioned, all these magnetic materials are isolated from the sample matrix using an external magnetic field, which is highly convenient. However, it is important to highlight that, when working with such strong magnets in the laboratory, suitable precaution should be taken, because they can stick to any metallic furniture of the laboratory or even to other magnets.

Although mNPs are the type of NP most extensively used in sample preparation, nonmagnetic NPs have also been used as sorbents in various extraction techniques, although in fewer applications. In this sense, Al2O3 and especially SiO2 NPs, have been the most commonly used, probably as a result of their stability and the fact that they can be functionalized or coated with other materials, particularly polymers (2,3).

Quantum Dots

Quantum dots (QDs) are defined as “small crystals containing a variable number of electrons that occupy well-defined, discrete quantum states and have electronic properties intermediate between bulk and a discrete fundamental particle” (32). QDs usually have diameters ~2–10 nm, and consist of a semiconductor core overcoated by a shell, and a cap that improves solubility in aqueous buffers (33). During synthesis, different compounds are added so that they ultimately form ligands on the surface of the core. Such ligands are key parameters in determining their applicability.

In general, QDs are characterized by poor extraction selectivity, so they are normally used as sorbents after a modification of their surface or their combination with other materials (3). Carbon-based QDs have been some of the most widely used for extraction purposes. They are a new class of environmentally friendly carbon materials with high water solubility, negligible toxicity, good stability, and small size (34). Graphene QDs, which were first fabricated 10 years ago, possess a graphene lattice inside the dots. They can be modified on their surface, like graphene. In general, QDs are in their infancy in extraction procedures, though they have found an important role in other disciplines.

Electrospun Nanofibres

Another current trend is the production and use of polymers with nanoscale fibrous structures, which can be achieved mainly by electrospinning (35), which is why they are frequently called electrospun nanofibres. Electrospinning relies on repulsive electrostatic forces to produce a solution of optimal viscoelasticity to form nanofibres. The analyte–sorbent interaction mechanisms are similar to those of conventional SPE polymers. The nanofibres most frequently used as sorbents have been those based on polystyrene and nylon 6 polymers (35). Nowadays, it is possible to modify the nanofibres pre- and post-electrospinning, so that a broad spectrum of materials is obtained, to be used mainly in SPE and SPME (36). Like other nanomaterials, electrospun nanofibres have also been combined with other materials to improve their performance (36).

Dendrimers

Dendrimers are polymer-based macromolecules with highly repetitive branched three-dimensional structures of several nanometers in size. Their properties mainly depend on the functional groups on their molecular surfaces, although sometimes they also depend on their internal cores. These structures can be built in a controllable manner, in which the end groups can be tailored and modified with desired functionalities (35,37).

With proper design of a dendrimer structure, good selectivity for various target molecules can be achieved (37). In fact, dendrimers can also be used to provide greater selectivity to other sorbents whose high extraction capacity has been demonstrated in order to improve their selectivity towards certain analytes. In this sense, dendrimers have been used to coat magnetic and nonmagnetic NPs, to modify other nanomaterials (such as the surface of CNTs), or even to form composites (37). Dendrimers act by encapsulating the target molecules, which have generally included dyes, polycyclic aromatic hydrocarbons (PAHs), or heavy metals.

Conclusions

Today, nanomaterials occupy an important place in current research and applications in analytical chemistry and, in particular, as extraction sorbents. A clear indicator of the exceptionally high interest in these materials is the extremely high number of applications that are being published every year.

The current variety of nanomaterials available, as well as their combinations, is quite high, providing an arsenal of sorbents ready for use, a good number of which have even been commercialized, though not always at an affordable cost.

The sorbent-based extraction procedure in which nanomaterials have been mostly commonly applied is dSPE, especially for nanomaterials with magnetic properties. Indeed, mNPs constitute one of the most widespread classes of nanomaterials used, thanks to their extraordinary high surface area, extraction capacity, chemical stability, and possibility and ease of functionalization and coating.

In general, when a new nanomaterial or combination of nanomaterials is used, suitable characterization to elucidate its morphology, composition, size, and so on, must be carried out, using complementary surface characterization techniques such as X-ray diffraction (XRD), thermogravimetric analysis/differential thermal analysis (TGA/DTA), gas adsorption isotherms, transmission electron microscopy (TEM), scanning electron microscopy (SEM), X-ray photoelectron spectroscopy (XPS) or infrared (IR), and UV–vis spectroscopy.

Given the excellent results provided by nanomaterials and the growing research into their synthesis, it is expected that the number of methodologies using such materials will continue to increase, though further research is needed to fully evaluate the convenience of their routine use in the laboratory. Furthermore, given that their synthesis is often complex and not so environmentally friendly, suitable efforts must be made in that direction. Finally, it should be highlighted that there is particular concern about the toxicity and environmental fate of many of these materials, which is associated with their extremely low size and sorption and binding properties, and which are still not fully described or understood.

Acknowledgements

The authors wish to acknowledge the support of the Fundación CajaCanarias (project 2016TUR07). C. Cairós thanks the Canary Agency of Economy, Industry, Trade and Knowledge (ACIISI) of the Canary Islands Government for the contract to support research activities of the International Research Campus (CEI) of the University of La Laguna.

References

- F.C. Adams, C. Barbante, Spectrochim. Acta B 86, 3–13 (2013).

- J. González-Sálamo, B. Socas‑Rodríguez, J. Hernández-Borges, and M.Á. Rodríguez-Delgado, TrAC- Trends Anal. Chem. 85, 203–220 (2016).

- B. Socas-Rodríguez, J. González‑Sálamo, J. Hernández-Borges, and M.Á. Rodríguez-Delgado, TrAC- Trends Anal. Chem. 96, 172–200 (2017).

- S. Garrigues, S. Armenta, and M. de la Guardia, Challenges in Green Analytical Chemistry (John Wiley & Sons, Hoboken, New Jersey, 2016).

- J. González-Sálamo. New Extraction Protocols for the Determination of Endocrine Disrupting Compounds in Samples of Environmental and Agri-Food Interest. PhD thesis, Universidad de La Laguna, San Cristóbal de La Laguna, Spain, October, 2018.

- P.H. Towler, J.D. Smith, and D.R. Dixon, Anal. Chim. Acta 328, 53–59 (1996).

- N. Sun, Y. Han, H. Yan, and Y. Song, Anal. Chim. Acta 810, 25–31 (2014).

- P. Rocío-Bautista, P. González-Hernández, V. Pino, J. Pasán, and A.M. Afonso, TrAC- Trends Anal. Chem. 90, 114–134 (2017).

- A. Gutiérrez-Serpa, J. González-Sálamo, and J. Hernández-Borges. Preparation Methods and Advantages of Nano-Sorbents for Food Contaminants Determination. Food Engineering Series (Springer Nature, Basel, Switzerland, 2019).

- L.M. Ravelo-Pérez, A.V. Herrera‑Herrera, J. Hernández-Borges, and M.Á. Rodríguez-Delgado, J. Chromatogr. A. 1217, 2618–2641 (2010).

- B. Socas-Rodríguez, A.V. Herrera-Herrera, M. Asension-Ramos, and J. Hernández-Borges, J. Chromatogr. A. 1357, 110–146 (2014).

- S. Lin, N. Gan, L. Qiao, J. Zhang, Y. Cao, and Y. Chen, Talanta 144, 1139–1145 (2015).

- W. Zhang, Z. Zhang, J. Zhang, J. Meng, T. Bao, and Z. Chen, J. Chromatogr. A. 1351, 12–20 (2014).

- R. dos A. de Jesus, L.F.S. Santos, S. Navickiene, and M.E. de Mesquita, Food Anal. Method. 8, 446–451 (2015).

- H. Zhao, N. Li, J. Li, X. Qiao, and Z. Xu, Food Anal. Method. 8, 1363–1371 (2015).

- Z. Li, C. Lei, N. Wang, X. Jiang, Y. Zeng, Z. Fu, L. Zou, L. He, S. Liu, X. Ao, K. Zhou, and S. Chen, J. Chromatogr. B. 1100–1101, 113–121 (2018).

- N. Li, D. Wu, N. Hu, G. Fan, X. Li, J. Sun, X. Chen, Y. Suo, G. Li, and Y. Wu, J. Agric. Food Chem. 66, 3572–3580 (2018).

- L. Zeng, X. Wu, Y. Li, D. Lu, and C. Sun, Anal. Methods 7, 543–550 (2015).

- N. Li, Z. Wang, L. Zhang, L. Nian, L. Lei, X. Yang, H. Zhang, and A. Yu, Talanta 128, 345–353 (2014).

- X. Hou, Y. Guo, X. Liang, X. Wang, L. Wang, L. Wang, and X. Liu, Talanta 153, 392–400 (2016).

- S. Lirio, W.-L. Liu, C.-L. Lin, C.-H. Lin, and H.-Y. Huang, J. Chromatogr. A. 1428, 236–245 (2016).

- B.-T. Zhang, X. Zheng, H.-F. Li, and J.-M. Lin, Anal. Chim. Acta 784, 1–17 (2013).

- B. Socas-Rodríguez, J. González-Sálamo, and J. Hernández-Borges, in C.D. García, A.G. Crevillén, and A. Escarpa, Eds. Carbon-based Nanomaterials in Analytical Chemistry (The Royal Society of Chemistry, London, UK, 2019).

- C.D. García, A.G. Crevillén, and A. Escarpa, Eds. Carbon-based Nanomaterials in Analytical Chemistry (Royal Society of Chemistry, London, UK, 2019).

- P. Rocío-Bautista, I. Pacheco-Fernández, J. Pasán, and V. Pino, Anal. Chim. Acta 939, 26–41 (2016).

- Y. Wang, M. Rui, and G. Lu, J. Sep. Sci. 41, 180–194 (2018).

- P. Rocío-Bautista, C. Martínez-Benito, V. Pino, J. Pasán, J.H. Ayala, C. Ruiz-Pérez, and A.M. Afonso, Talanta 139, 13–20 (2015).

- H.-L. Qian, C.-X. Yang, W.-L. Wang, C. Yang, and X.-P. Yan, J. Chromatogr. A. 1542, 1–18 (2018).

- J. Wang, J. Li, M. Gao, and X. Zhang, TrAC- Trends Anal. Chem. 108, 98–109 (2018).

- J. González-Sálamo, A.V. Herrera-Herrera, C. Fanali, and J. Hernández-Borges, LCGC Europe 29, 180–192 (2016).

- Á. Ríos and M. Zougagh, TrAC- Trends Anal. Chem. 84, 72–83 (2016).

- V.G. Reshma and P.V. Mohanan, J. Lumin. 205, 287–298 (2019).

- Y. Ghasemi, P. Peymani, and S. Afifi, Acta Bio. Med. Atenei Parm. 80, 156–165 (2009).

- D. Yang, X. Li, D. Meng, and Y. Yang, J. Mol. Liq. 261, 155–161 (2018).

- J. Płotka-Wasylka, N. Szczepańska, M. de la Guardia, and J. Namieśnik, TrAC- Trends Anal. Chem. 77, 23–43 (2016).

- E.M. Reyes-Gallardo, R. Lucena, and S. Cárdenas, TrAC- Trends Anal. Chem. 84, 3–11 (2016).

- M. Sajid, TrAC- Trends Anal. Chem. 98, 114–127 (2018).

Javier González-Sálamo, Diana Angélica Varela-Martínez, Carlos Cairós, and Javier Hernández‑Borges are with the Universidad de La Laguna, in San Cristóbal de La Laguna, Spain. Miguel Ángel González-Curbelo is with Universidad EAN in Bogota, Colombia. Direct correspondence to: amatheson@mjhlifesciences.com

Thermodynamic Insights into Organic Solvent Extraction for Chemical Analysis of Medical Devices

April 16th 2025A new study, published by a researcher from Chemical Characterization Solutions in Minnesota, explored a new approach for sample preparation for the chemical characterization of medical devices.

Study Explores Thin-Film Extraction of Biogenic Amines via HPLC-MS/MS

March 27th 2025Scientists from Tabriz University and the University of Tabriz explored cellulose acetate-UiO-66-COOH as an affordable coating sorbent for thin film extraction of biogenic amines from cheese and alcohol-free beverages using HPLC-MS/MS.

Multi-Step Preparative LC–MS Workflow for Peptide Purification

March 21st 2025This article introduces a multi-step preparative purification workflow for synthetic peptides using liquid chromatography–mass spectrometry (LC–MS). The process involves optimizing separation conditions, scaling-up, fractionating, and confirming purity and recovery, using a single LC–MS system. High purity and recovery rates for synthetic peptides such as parathormone (PTH) are achieved. The method allows efficient purification and accurate confirmation of peptide synthesis and is suitable for handling complex preparative purification tasks.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)