Molecular Correlative Material Characterization: Advantages for Polymer Analysis Using Liquid Chromatography

This article discusses innovation around the molecular structure of polymeric materials—an indispensable part of modern society—with a specific focus on sustainability. This field of research, so-called molecular correlative material characterization (MCMC), will enhance the transition into new sustainable functional copolymers.

Polymeric materials are an indispensable part of modern society. The functionality of polymers correlates heavily with their interrelating molecular features. There is a strong innovation focus on sustainability of functional polymers, which further increases the complexity of their molecular structure. Consequently, a thorough understanding of the relation between molecular structure, including their interrelating distributions and their final properties, is a crucial aspect in polymer research and innovation. A well-developed analytical toolbox of high-end methodologies and technologies is needed to elucidate the molecular structures of polymers and their distributions. The analysis of the structures and various distributions of these complex copolymers is referred to as molecular correlative material characterization. Liquid chromatography (LC) is an important technology to help determine the molecular structure and the distribution of polymers. Recent developments in LC in the areas of sample preparation, mono-distribution separations, and their hyphenation into fully orthogonal and optimized two‑dimensional liquid chromatography (2D-LC) separations have unlocked the ability to conduct molecular correlative material characterization. This article will discuss these recent developments and the ongoing research towards the coupling of different information sources with respect to chemical structure distributions of complex copolymers.

Applied as a coating or bulk material, polymers have become vastly important to our society, with applications ranging across packaging, textiles, construction, automotive, furniture, toys, and electronic equipment.

The development of polymers can generally be classified into two main areas of innovation. The first aims to improve sustainability by reusing materials to reduce the carbon footprint. Examples include bio-based and environmentally-friendly materials, life cycle management, and microplastic reduction. The second is the development of higher performing functional polymers with special structural features. These features can be thermal or mechanical properties, but also functionalities tailored to the application and aimed at, for example, drug release, air purification, light emission, self-cleaning, or sensory properties. Functional polymers are often applied as coatings and this introduces additional properties to the bulk material (substrate) of the coating. These coatings have found a widespread use in specific high-performance applications ranging from hygiene (antibacterial), cosmetics (hair and skin care), environmentally-friendly waterborne coatings, special packaging (tactile perception), medical applications (drug release, wound healing, slippery feel), and agriculture (seed coatings), to photo/microelectronics (solar panels).

Together, these two strong driving forces for innovation have resulted in a dramatic increase in the overall complexity of the molecular structure and their interrelated distributions. Indeed, copolymers composed of much more than three different monomers or oligomers are no longer exceptional. As a result, the complexity of the copolymers increases the dimensionality of the sample, featuring interrelating distributions in molar mass (MWD), chemical composition (CCD), block length (BLD), functionality-type (FTD), molecular architecture (MAD), and branching (BD).

As the properties of these copolymers correlate heavily with their molecular features, precision chemistry aimed at introducing tailored functionality requires an in-depth understanding of the complex molecular structures. A well‑known example is the relation between the various chemical distributions. This branch of analytical chemistry can be referred to as molecular correlative material characterization (MCMC), and is aimed at determining the various chemical distributions of these polymers and their dependency on one another using chromatographic approaches. To achieve this, liquid chromatography (LC)-based methods have been hugely important and progress over the last five years will be discussed here.

Correlative Information Through Making Modifications to the Polymer Prior to Analysis

Sample preparation is often regarded as a way to dissolve the sample without destroying the polymer. However, it can also be used to add chemical features to the polymeric structure and enhance the efficacy of the separation or detection.

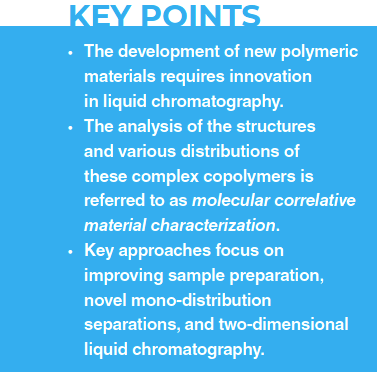

One approach focuses on the labelling of specific functionalities, so-called derivatization or tagging. In contrast to life sciences, this is not as well developed in (synthetic) polymer analysis, due to the change in derivatization efficiency over the full molar mass range (1), and so this approach is less frequently applied to the analysis of larger polymers. Brooijmans et al. (2) recently demonstrated that carboxylic acid-functionality in copolymers can be derivatized with a high degree of reproducibility, speed, and selectivity (>99% derivatization efficiency over the whole MWD range) using phenacylbromides. The developed derivatization technique was applied to gain more insight into the stabilization of polyacrylates emulsions. The distribution of carboxylic-acid functionalities along the polyacrylate backbone was determined by applying the phenacylbromide derivatization, followed by size-exclusion chromatography (SEC), so-called tag-SEC. UV and refractive index (RI) detection was used for the SEC separation of the derivatized copolymers, thus enabling the quantitative determination of the acid-functionality content for each molar mass fraction. Beside the MWD, this approach also yielded the concentration of the incorporated acidic monomer and its distribution over the molar mass. Figure 1 demonstrates that this additional information yields more insight in the actual incorporation of these monomers, linking copolymer synthesis conditions to copolymer properties.

In general, a wide variety of chromatographic and spectroscopic techniques can be applied as an alternative to the above, for example LC, titration, nuclear magnetic resonance (NMR); however, none of these approaches is able to determine the monomeric-functionality distribution such as acid functionality as a function of the MWD directly, as shown by the tag-SEC approach. Moreover, the derivatization approach can be applied to solve other challenges in polymer analysis. One example is the determination of the overall chemical composition of copolymers by pyrolysis–gas chromatography (Py–GC) (3). The main advantage of this approach is that phenacyl esters produced by precolumn derivatization prevent the dehydration and decarboxylation effects commonly formed if hydrophilic monomers, for example, (meth)acrylic-acid containing copolymers, are subjected directly to pyrolysis. This enables the determination of the copolymer composition including the hydrophilic functional monomers.

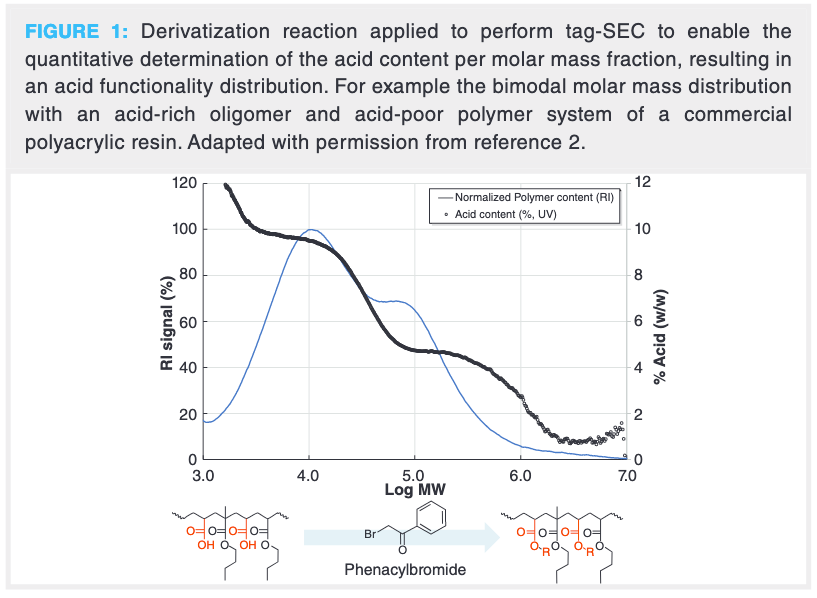

Another approach to obtain the correlation of the chemical composition distribution of a copolymer with morphology such as particle-size distribution (PSD) is the precolumn degradation of copolymers by enzymes. This was demonstrated by Wouters et al., who investigated enzymatic degradation of polyester‑based nanoparticles, both in-solution and by an immobilized-enzyme reactor (IMER) (4). The authors demonstrated for the first time the implementation of such an IMER in a SEC system for online degradation and subsequent analysis of the copolymer degradation products (Figure 2). The effect of residence times ranging from 12 s to 4 min on copolymer degradation was assessed. IMER-assisted degradation takes minutes and is thus much faster compared to in-solution degradation, which requires anything from several hours up to several days. This unlocked the use of such reactors as selective modifiers prior to separation. Groenenveld et al. investigated the incorporation of this IMER technology in comprehensive two-dimensional liquid chromatography (LC×LC) modulation interfaces to determine the molecular structure of drug delivery nanosized particles (5). They showed the applicability for poly(lactic acid-co-glycolic acid)-block-poly(ethylene glycol)-block-poly(lactic acid-co-glycolic acid) copolymers nanoparticles filled with a dye. They were able to determine, online, the composition of these nanoparticles by characterizing the dye as the composition of the copolymer. While research is ongoing, this example already clearly demonstrates that the use of selective degradation can help to obtain interrelated distribution information such as MWD as a function of PSD, as well as the composition as a function of PSD.

Determining the Correlation Between Property Distributions Through Specific Detection of the Polymer

Detection is also key to obtaining accurate and precise information on the correlation between the different chemical distributions in the molecular structure of polymers from both a quantitative and qualitative perspective.

The quantitative aspects of all detectors for LC-based copolymer separations were recently extensively reviewed by Knol et al. (6). The main observation of the work was that current detectors are not universally applicable in the quantitation of copolymers with varying compositional features. This renders most techniques not applicable to contemporary complex polymers when the chemical structure is unknown. As a consequence, accurate quantitative analysis of copolymer separations is very challenging and inhibits the development of new sustainable materials. Therefore, the authors found that current research efforts focus on the development of more universal detectors, such as LC-flame ionization detection, and new calibration protocols for evaporative light scattering detectors (ELSD).

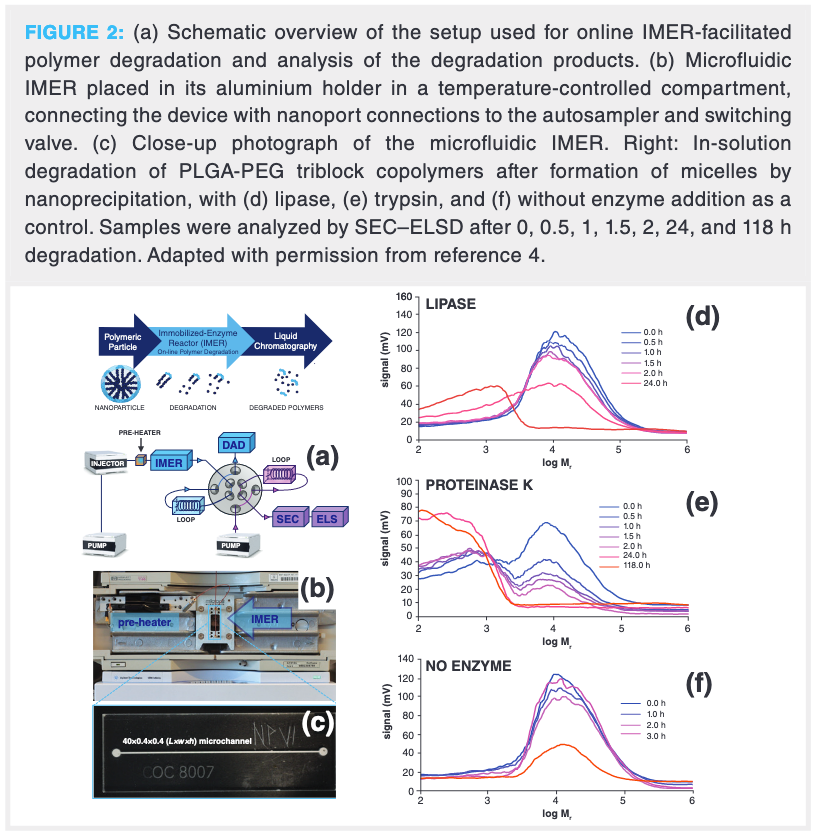

There are several recent developments of interest in chemical-composition sensitive (information-rich) detectors. The coupling of chromatographic separations with mass spectrometric (MS) identification of copolymers has been reported by various publications and reviews (7,8). In general, electrospray ionization mass spectrometry (ESI-MS) has been extensively employed for polymer characterization because the hyphenation of LC to MS facilitates the determination of chemical heterogeneity and molar mass. Although Nohmi and Fenn (9) demonstrated that PEG up to 5 MDa could be ionized with ESI-MS, no structural information could be obtained from these MS spectra. The complex MS spectra for copolymers of high sample dimensions limited the applicability of ESI-MS for broadly distributed or higher molar mass copolymers to a few kDa. This rendered mass spectrometry limited to complex copolymers of low molar mass at best and is thus mainly focused on identification of the chemical composition and structure of copolymers with limited sample dimensions. To expand the mass range for complex copolymers using MS, the enhancement of the ionization efficiencies by the use of a supercharging agent was explored. Steinkoenig et al. (10) used supercharging agents to extend both the polarity range and the ionization efficiency, thus unlocking MS detection of higher MWD. The authors illustrated the concept by using a chlorine attachment and the addition of supercharging agents (sulfolane or propylene carbonate) and found that even medium-sized nonpolar polymers, such as polystyrene, could be analyzed with ESI-MS using this technique.

By applying this ionization process, the authors were able to analyze polystyrene and polybutadiene of masses up to 18 kDa and 10 kDa, respectively. Recent work from Voeten et al. (11) showed the successful implementation of 3-nitrobenzylalcohol (3-NBA) as a supercharging agent for the ionization of copolyester resins. Groeneveld et al. (12,13) applied this supercharging agent to enable the analysis of 10 kDa copolyesters by MS. As seen in Figure 3, the number of detected charge states increased from only [M+2Na]2+ to [M+10Na]10+ using 3-NBA. The authors applied the technique both for SEC–MS as well as 2D-LC with MS detection.

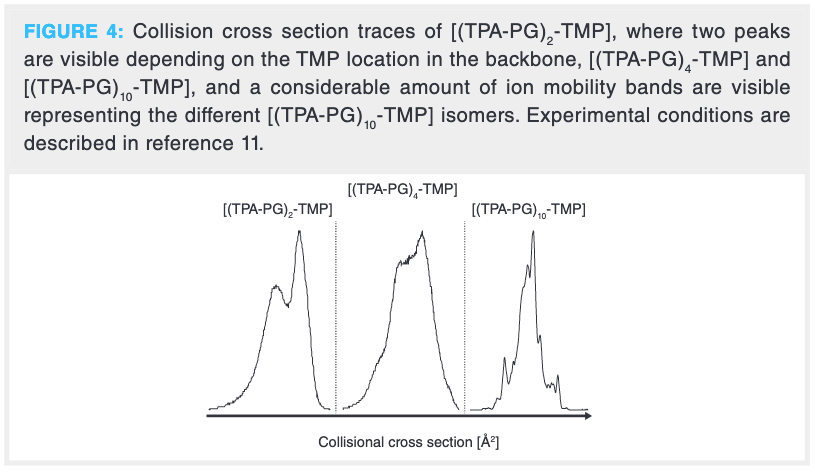

The degree of branching is another important property of industrial polymeric materials. One useful innovation in this context has been the development of ion‑mobility spectrometry (IMS)-MS (14). IMS can be hyphenated to MS as well as LC and can obtain unique information on both composition and structure (15). However, similar to MS, all publications related to IMS on polymers are limited to molar mass below a few kDa and mainly applied on polymers with a low sample dimensionality, such as homopolymers. With increasing molecular weight distribution, the spherical conformation of the polymer chains become independent of the molar mass and structure, which renders it less applicable for more complex copolymers. This was recently confirmed by Voeten et al., who used LC–IMS-MS to investigate the branching of isomeric copolyesters (11). The time‑based IMS separation and subsequent MS/MS allowed the identification of the separated species. While distinct branching could be observed, it was shown that insufficient resolution was obtained to enable clear distinction of all structural isomers present in the copolymer (Figure 4). Current research efforts focus on coupling IMS to two-dimensional liquid chromatography (2D-LC) frameworks to investigate the feasibility of identification of copolyester species with a higher MWD.

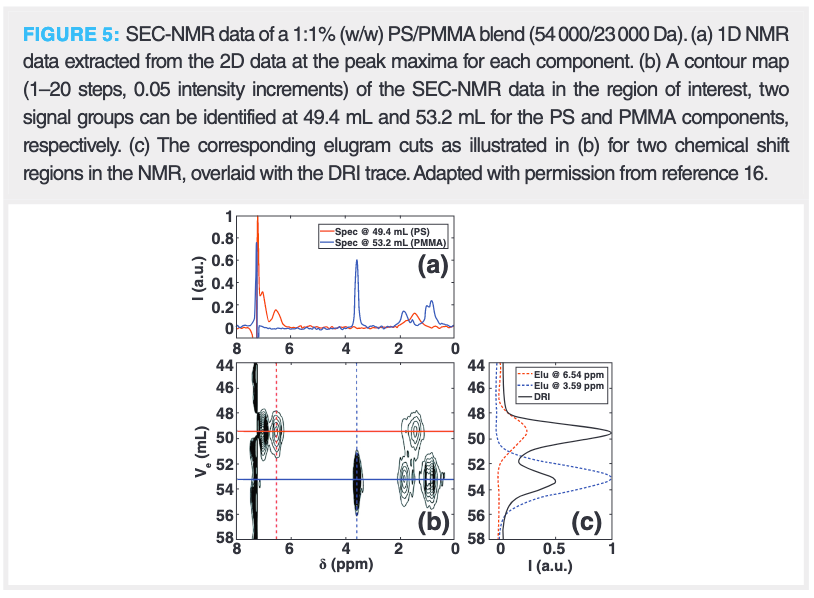

Another interesting development in the field of detection is the coupling of LC with molecular spectroscopy, such as NMR and Fourier-transform infrared spectrometry (FT-IR). Despite its superior selectivity, the lack of sensitivity of NMR renders the technique difficult to hyphenate with LC, in particular with respect to sample size, eluent composition, and sampling frequency of the NMR spectrometer. Wilhelm et al. (16) optimized and applied an LC–NMR system to obtain MWD as a function of chemical composition in relatively fast analysis times (see Figure 5).

SEC and IR have also been hyphenated within the context of polymer analysis to study the MWD and CCD (17). Using a custom-built external cavity quantum cascade laser mid-IR spectrometer, significant improvement of sensitivity was achieved. Detection limits were found to be roughly 30 times lower than previously reported for SEC–FT-IR.

Determining the Correlation Between Property Distributions Through Two-Dimensional LC

From the point of sample dimensionality, 2D-LC is one of the logical approaches to characterize the variation in structure of polymers that feature multiple distributions (5). The first decade of the millennium saw the development of several useful methods for the analysis of polymers of limited complexity. However, the majority of 2D-LC methods fail to yield useful information for more sophisticated copolymeric systems. For example, application of a reversed‑phase separation in one dimension will see the enthalpic differences applied to the complete copolymer (that is, all monomer types), or polarities will have their own contribution to the overall enthalpy of the system. As a result, no selective mono-distribution separation is observed, yielding non‑interpretable 2D‑LC chromatograms with all distributions superimposed on top of each other. Therefore, there is a strong need for very selective mono-distribution separations, which can be applied in a 2D-LC setup to obtain MCMC information.

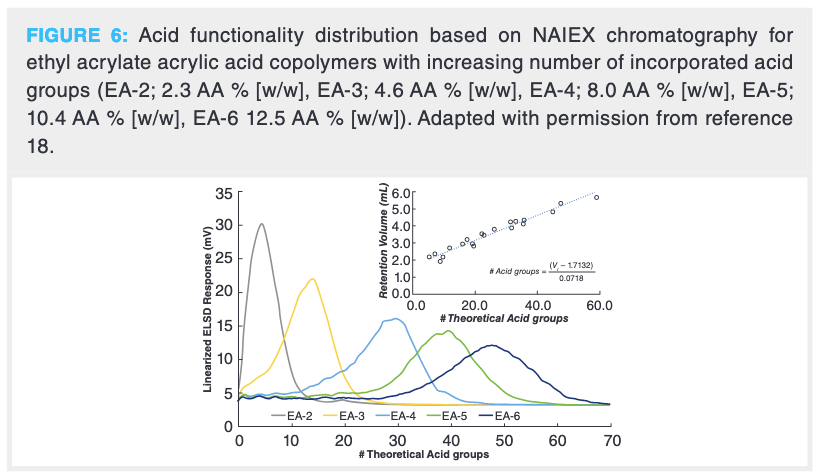

A good example of a recent mono‑distribution separation of a complex copolymer is the use of non-aqueous ion‑exchange chromatography (NAIEC) for the separation of the carboxylic acid‑functionality in polyacrylates by Brooijmans et al. (18). The authors developed a novel NAIEC separation based on the number of deprotonated carboxylic-acid groups along the backbone chain of polyacrylates. The use of the polar aprotic N-methyl-2-pyrrolidone was found to be a suitable solvent for both the polymers and organic salts, such as the superbase 1,1,3,3-tetramethylguanidine. The retention in NAIEC appeared to be dominated by the number of acid groups incorporated in the copolymers. The influence of the polarity of the comonomer separation was found to be very limited, indicating little or negligible hydrophobic interactions. The NAIEC separation allowed the authors to determine the acid-functionality distribution (AFD) of the copolymers, as shown in Figure 6. The proposed mode of polymer chromatography is an interesting alternative to conventional normal‑phase and reversed-phase separations and is particularly useful for obtaining acid‑functionality distributions of complex copolymers. Brooijmans et al. compared the NAIEC separation with traditional normal-phase LC and reversed-phase LC methods and found that the latter failed to accurately describe a unique distribution for these complex copolymer systems as opposed to the NAIEC method. The authors suggested that the NAIEC method would be well-suited for incorporation as one of the dimensions in a 2D-LC system, providing a fully orthogonal acid‑functionality distribution as a function of a second-dimension MWD determination.

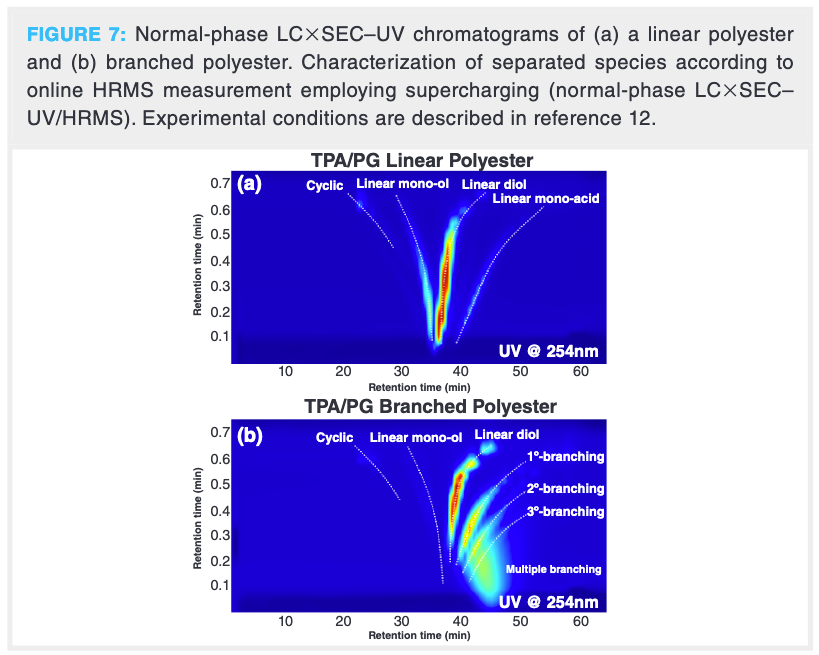

The power of 2D-LC was also shown by Groeneveld et al. (12,19) when applying very selective mono-distribution separations. The authors determined the correlation of end-group functionality and molar mass with the chemical composition distribution of copolyesters by comprehensive normal-phase LC×SEC hyphenated with both UV–vis light spectroscopy and high-resolution mass spectrometry (normal-phase LC×SEC‑UV–vis/HRMS) (19). By hyphenating the normal-phase LC×SEC separation, the end-group functionality relation with MWD could be determined, while the parallel detection (HRMS/UV–vis), identification, and quantification of chemical composition over the combined FTD×MWD distributions could be performed (Figure 7). To provide chemical composition information of higher molar mass species, supercharging technology was used to increase the detected charge states with HRMS. Before this, there was no analytical method available that could characterize the interrelation of such distributions in a single analysis. Overall, the method can function as a universal platform to characterize the interrelation between carboxyl or hydroxyl end-group functionalities, molar mass distributions, and the chemical composition distribution of polyester samples. As a consequence, it is not surprising that the developed normal‑phase LC×SEC–UV–vis/HRMS platform is a valuable tool for characterizing copolyesters in an industrial setting.

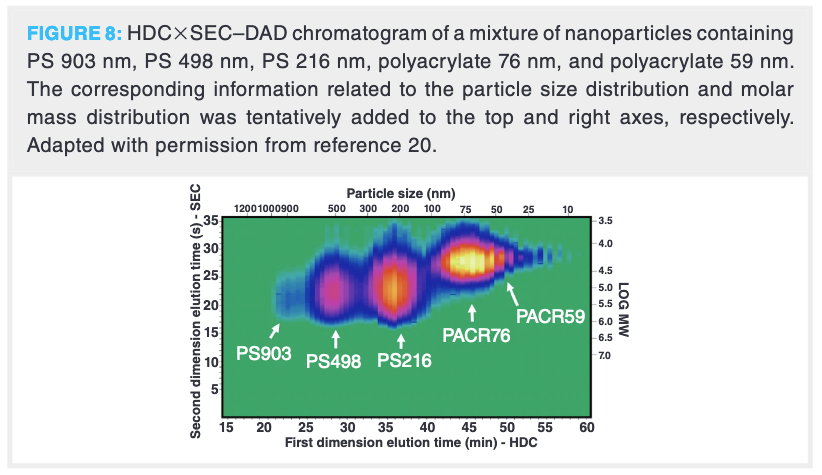

Another example demonstrating the power of 2D-LC for MCMC purposes is the coupling of two truly independent mono‑distribution separations (20). A 2D‑LC setup was developed, which combined hydrodynamic chromatography (HDC) in the first dimension to separate polymeric nanoparticles in their dispersed state based on size, with ultrahigh‑performance (UHP)SEC in the second dimension to separate the constituting copolymer molecules according to their molecular mass. A chip‑based mixer was incorporated to transform the sample by dissolving the separated nanoparticles from the first dimension effluent online with tetrahydrofuran. The eluting polymer bands were focused using stationary‑phase‑assisted modulation (SPAM) to enhance sensitivity, and the water from the first dimension eluent was largely eliminated to allow interaction-free SEC. Using the developed system, the combined two-dimensional distribution of the particle size and the molecular size of a mixture of various polystyrene and polyacrylate nanoparticles was obtained within 60 min, as shown in Figure 8. This approach offers an insight into the interrelation between the particle size and the molar mass distribution of the intrinsic polymers. To show the applicability of this new approach, the newly developed 2D-LC system was applied to industrial waterborne emulsions comprising hydrophobic, hydrophilic, and charged moieties, viz. stabilized dispersions of poly[(methyl methacrylate)-co-(butyl acrylate)-co-(methacrylic acid)]-nanoparticles in water (21). The result is a simultaneous determination of the size distribution of nanoparticles and the molecular weight distribution of the constituting polymers as a function of the particle size. It was consistently found that, within a single population of particles, the weight-average molar mass increased with particle size. The authors furthermore demonstrated that the proposed approach enabled fundamental studies into the process of particle formation and copolymer growth during emulsion polymerization. Indeed, new insights were obtained in nanoparticle formulations with very narrow particle size distributions, which are particularly difficult to study by other means.

Discussion and Conclusions

The applicability of copolymers correlates heavily with their molecular features, which emphasizes the need for a thorough understanding of the relation between their molecular distribution structures. This field of research, so-called molecular correlative material characterization (MCMC), will enhance the transition into new sustainable functional copolymers. Recent developments and ongoing research towards the coupling of different information sources with respect to chemical structure distributions of copolymers have been discussed here. The field is certainly moving towards MCMC, and generating mono-distribution information is therefore key here (that is, each present chemical-feature distribution is fully separated from others). From the latest developments we can see three main areas of development.

The first is the development of precolumn sample preparation strategies, not only dissolution of the copolymer without destroying information, but also combining this with selective modifications such as derivatization or degradation to enable mono-distribution information. The second angle of research focuses on the separation. Here, there is a need for truly mono-distribution separations of these high copolymer dimensions to avoid superimposition of the various distributions on each other. These mono-distribution separations are well suited to be incorporated into new 2D-LC platforms for MCMC. Often, this will require incorporation of chemical or physical active modulation, such as the IMER, to unlock hyphenation of incompatible separations, but also to obtain very selective mono-distribution information and their correlation. Finally, the detection is, of course, indispensable, yet, given the opportunities, this angle does not receive the attention that is deserved. Surprisingly, only a limited number of groups work in this field. Of particular interest are the developments of technologies such as online NMR, IR, and IMS (9,10,13,15), as the field pursues the development of a universal quantification detector (for example, flame ionization detection for LC).

By approaching the problem from these three angles, analytical chemists are working hard to converge on a solution to unlock MCMC. This is certainly an exciting time to operate in this field, with opportunities across all disciplines. We expect many different and interesting developments to emerge in the years to come.

References

- Y. Mengerink et al., J. Chromatogr. A 878(1), 45–55 (2000).

- T. Brooijmans et al., Anal. Chim. Acta 1072, 87–94 (2019).

- T. Brooijmans, R. Okhuijsen, I. Oerlemans, P.J. Schoenmakers, and R. Peters, J. Chromatogr. A 1560, 63–70 (2018).

- B. Wouters et al., Anal. Chim. Acta 1053, 62–69 (2019).

- G. Groeneveld, B.W.J. Pirok, and P.J. Schoenmakers, Faraday Discuss. 218, 72–100 (2019).

- W.C. Knol, B.W.J. Pirok, and R.A.H. Peters, J. Sep. Sci. 44(1), 63–87 (2021).

- S. Crotty, S. Gerişlioğlu, K.J. Endres, C. Wesdemiotis, and U.S. Schubert, Anal. Chim. Acta 932, 1–21 (2016).

- K. De Bruycker, A. Welle, S. Hirth, S. J. Blanksby, and C. Barner-Kowollik, Nature Reviews Chemistry 4, 257–268 (2020).

- T. Nohmi and J.B. Fenn, J. Am. Chem. Soc. 114(9), 3241–3246 (1992).

- J. Steinkoenig, M.M. Cecchini, S. Reale, A.S. Goldmann, and C. Barner-Kowollik, Macromolecules 50(20), 8033–8041 (2017).

- R.L.C. Voeten et al., Journal of the American Society for Mass Spectrometry submitted (2020).

- G. Groeneveld et al., Anal. Chem. submitted (2020).

- I. Kohler, M. Sun, G. Groeneveld, and A.F.G. Gargano, LCGC North Am. 38(9), 2–11 (2020).

- L. Charles, C. Chendo, and S. Poyer, Rapid Commun. Mass Spectrom. 34(S2), 1–23 (2020).

- D. Morsa, T. Defize, D. Dehareng, C. Jérôme, and E. De Pauw, Anal. Chem. 86(19), 9693–9700 (2014).

- C. Botha, J. Höpfner, B. Mayerhöfer, and M. Wilhelm, Polym. Chem. 10(18), 2230–2246 (2019).

- J.M. Kübel et al., Macromol. Rapid Commun. 40(18), 1900228 (2019).

- T. Brooijmans, P. Breuer, P.J. Schoenmakers, and R.A.H. Peters, J. Chromatogr. A 1626, 461351 (2020).

- G. Groeneveld et al., J. Chromatogr. A 1569, 128–138 (2018).

- B.W.J. Pirok et al., Anal. Chem. 89(17), 9167–9174 (2017).

- B.W.J. Pirok et al., Anal. Chim. Acta 1054, 184–192 (2019).

Ron Peters is principal scientist in polymer analysis and characterization at the Covestro (former DSM Resins and Functional Materials), The Netherlands. He is part-time professor of bioterials analysis at the Faculty of Science (FNWI) of the University of Amsterdam (UvA), The Netherlands.

Bob Pirok is assistant professor in chemometrics and advanced separations at the Faculty of Science (FNWI) of the University of Amsterdam (UvA) and visiting professor at Gustavus Adolphus College (Minnesota, USA) in the group of Dwight Stoll.

Ynze Mengerink is principal scientist in analytical chemistry within DSM Materials Science Center, The Netherlands.

New Method Explored for the Detection of CECs in Crops Irrigated with Contaminated Water

April 30th 2025This new study presents a validated QuEChERS–LC-MS/MS method for detecting eight persistent, mobile, and toxic substances in escarole, tomatoes, and tomato leaves irrigated with contaminated water.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)