Market Profile: Continuous Flow Analysis and Discrete Analyzers

In continuous flow analysis (CFA), a sample is injected into a flowing carrier solution passing rapidly through small-bore tubing.

In continuous flow analysis (CFA), a sample is injected into a flowing carrier solution passing rapidly through small-bore tubing. The sample is mixed with a reagent, which reacts with the sample to develop a color and determine the sample concentration. The use of carefully controlled flow conditions ensures that the color development reaction is reproducible, so that the color measurement need not wait until the reaction has gone to completion.

There are several technologies of CFA, including segmented flow analysis, which uses turbulent flow conditions that allow for complete sample dispersion, flow injection analysis, and sequential injection analysis, which uses laminar flow existing in the narrow-bore tubing to mix with the reagent to eliminate the need for air bubble partitioning.

In contrast to CFA, discrete analyzers keep samples separate throughout the testing process, dispensing precise amounts when required. Rotating individual cuvettes through the instrument instead of releasing the sample in a continuous stream cuts down on reagent waste and can produce hundreds of results per hour.

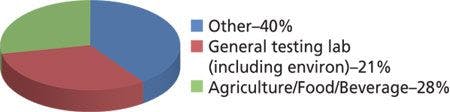

2012 CFA and discrete analyzers demand by industry.

CFA and discrete analyzers are used in environmental applications for measuring analytes such as ammonia, chloride, nitrite, phosphate, and others. The systems are also used in food and beverage, chemical testing, and pharmaceutical laboratories. Although CFA is a well-established technique for industrial applications, the prospect of cutting testing and consumable costs, and the ease of operation, have prompted many laboratories to transfer methods from CFA to discrete analyzers.

Currently, the United States and Europe account for about nearly three-quarters of the worldwide market for CFA and discrete analyzers. Although the Latin American and Asia Pacific markets are comparatively smaller for CFA and discrete analyzers, these regions continue to expand rapidly and offer solid growth opportunities. Environmental applications are estimated to account for nearly a third of the overall demand driven by wastewater and drinking water analysis. Agriculture and food and beverage is also a significant market with about 28% of the market share. Other industries using the technology include contract research organizations, pharmaceutical, government testing, utilities, and biotechnology.

The foregoing data were extracted and adapted from SDi's newly published Electrochemistry & Related Technologies Report. For more information, visit www.strategic-directions.com

Top Execs from Agilent, Waters, and Bruker Take the Stage at J.P. Morgan Healthcare Conference

January 16th 2025The 43rd Annual Healthcare J.P. Morgan Healthcare Conference kicked off in San Francisco earlier this week. Here’s what top executives from Agilent, Bruker, and Waters, discussed during the event.