Improved Internal Diameter Control of Tubing Used for Gas Chromatography

Synthetic fused silica capillary tubing is used in the manufacture of most gas chromatography (GC) columns. In this note, we discuss recent advances in the dimensional control of the most popular tubing sizes.

Ahistorical review of the dimensional specifications for flexible synthetic fused silica capillary reveals a clear effort to reduce both i.d. and o.d. tolerances. Previous work summarized the changes in published specifications and presented empirical data on i.d and o.d. variability (1). Additional studies examined in-draw stability (2). Efforts to further improve the dimensional stability of tubing used to manufacture GC columns is warranted by the potential for improved chromatographic performance, as well as by ease of column use as the industry moves toward plug and play concepts. This application note provides a comparative review of these critical dimensional parameters, with a focus on the i.d.

Experimental

Capillary tubing employed in this study included TSP250350 (0.25 mm i.d.), TSP320450 (0.32 mm i.d.), and TSP530660 (0.53 mm i.d.). The tubing was manufactured using current draw conditions and operating parameters. Of noted difference to previous work, improvements have been implemented in the integration of new control limit concepts and trend monitoring software algorithms.

Measurements were collected using an Olympus PME3 inverted microscope, which was calibrated and configured as reported previously (1). Gauge R&R studies continue to be conducted so that operator contributions to variability are understood.

Over the period of the study samples were collected and measured from both ends of every spool of material produced. The study time frame ensured a minimum of 1400 sample values (N >1400).

Results

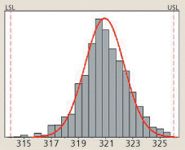

A summary of both past and present statistical data for the capillary i.d. can be found in Table I. Mean values are on target for all products studied. The standard deviation on all products has decreased, indicating an improvement in process control. The Cpk values for i.d. obtained in the past study ranged from 1.02 for 0.53 mm tubing to 1.23 for 0.25 mm tubing. These have improved to 1.12 and 1.55, respectively. Recall that Cpk quantifies the process capability and is defined as the ratio of tolerance to 6σ. A Cpk value of 1.0 or better suggests that the process is in control. The reader is reminded that both ends of every spool produced is physically measured and must be within specification for release to the market. For comparative purposed, a histogram of TSP320450 is shown in Figure 1.

Table I: Summary of GC tubing study results, past and present

Data on o.d. has shown similar improvements, although they have not been as dramatic. It should be noted that primary efforts have focused on reducing i.d. variability.

Figure 1: Histogram of TSP320450 i.d. data, N = 2094.

Conclusion

Continued efforts by Polymicro's production team have resulted in an overall improvement in both i.d. and o.d. variation, with i.d. standard deviations being reduced by as much as 20%. Polymicro continues to evaluate its manufacturing and metrology processes in an effort to insure the tightest tolerances in the industry.

References

(1) J.Macomber, P.Nico, and G.Nelson, LCGC App.Ntbk. June 2004, p. 71.

(2) J.Macomber and P.Nico, LCGC App. Ntbk. Feb. 2005, p. 55.

Polymicro Technologies, a Subsidiary of Molex

18019 North 25th Avenue, Phoenix, AZ 85023

tel. (602) 375-4100, Fax: (602) 375-4110

Website: www.polymicro.com

The Benefits of Custom Bonded Silica

April 1st 2025Not all chromatography resins are created equal. Off-the-shelf chromatography resins might not always meet the rigorous purification requirements of biopharmaceutical manufacturing. Custom bonded silica from Grace can address a wide range of separation challenges, leading to real performance improvements. Discover more about the latest innovations in chromatography silica from Grace, including VYDAC® and DAVISIL®.

5 Things to Consider When Selecting a Chromatography Silica

April 1st 2025Particularly in the pharmaceutical industry, drug purity isn’t just a goal – it’s essential for achieving safety, stability and efficacy. However, purification is easier said than done, especially with challenging molecules like DNA and RNA “oligonucleotides,” due in large part to their diversity and the range of impurities that can be generated during production. Enter DAVISIL® chromatographic silica, with a wide range of pore diameters and particle sizes to meet your specific application, performance and sustainability requirements. Before you choose the chromatography resin for your next purification application, take a look at these 5 considerations.

MilliporeSigma: Ultrapure Water for Sensitive LC-MS Analysis of Pesticides

March 25th 2025The aim of the study was to illustrate the efficiency of Milli-Q® water purification systems in eliminating pesticides from tap water, thereby producing and delivering reliable and consistent-quality ultrapure water suitable for pesticides analysis