Ensuring the Safety of the Food Supply: Speeding Up Arsenic Speciation Analysis

Special Issues

Speciation analysis of elemental contaminants in food and beverages has received much attention in recent years. Recent regulations limit inorganic arsenic, taking into account that arsenic toxicity is dependent on the species present. The analysis procedure thus needs to be able to differentiate inorganic from organic arsenic forms. LC-ICP-MS is commonly used for separation and detection of arsenic species, with the most widely used implementation being based on ion exchange and characterized by relatively long run times. Testing of increasing sample numbers means that analysis speed becomes a focal point for potential improvements. We developed a method based on ion interaction chromatography, allowing a reduction in run times to

Speciation analysis of elemental contaminants in food and beverages has received a lot of attention in recent years. Recent regulations limit inorganic arsenic, taking into account that arsenic toxicity is dependent on the species present. Thus, the analysis procedure needs to be able to differentiate inorganic from organic arsenic forms. Liquid chromatography–inductively coupled plasma-mass spectrometry (LC–ICP-MS) is commonly used for the separation and detection of arsenic species, with the most widely used implementation based on ion exchange and characterized by relatively long run times. Testing of increasing sample numbers means that analysis speed becomes a focal point for potential improvements. We developed a method based on ion interaction chromatography, allowing a reduction in run times to <3 min. The method was applied to a range of food and beverages samples. Here we discuss the results of these analyses and associated method validation tests.

With the expanding knowledge of element species and their distribution in foods, elemental speciation analysis has received increasingly wider attention by the food industry. The relevance of speciation analysis for the elements As, Se, Cr, and Hg has long been established based on the significant toxicity differences between the species of these elements. For arsenic, the number of identified species found in food is still growing, as evidenced by new research findings into arsenolipids (1); therefore, our knowledge of the biochemistry and toxicity of arsenic-containing biomolecules is also still expanding. It is a very active research field, and most new findings have been made in aquatic species and seafood. For terrestrially grown food, the number of arsenic species is more limited. For this report we investigated rice and juice, which have been the target of recent regulatory oversight that singles out and limits the toxic inorganic arsenic forms.

The increased demand for testing requires methods that are fast, sensitive, and sufficiently robust to cope with the matrix changes associated with various food products being subjected to extraction and analysis. Various methods exist to analyze for inorganic arsenic, including hydride generation coupled to spectrometric detection (2) and the development of field kits (3). The gold standard for this analysis, however, is liquid chromatography–inductively coupled plasma-mass spectrometry (LC–ICP-MS). It is the most widely used method for arsenic speciation (4) and is investigated in this study. The methodology to separate and quantitate common arsenic species by LC–ICP-MS is mature and well established. However, one disadvantage of current LC–ICP-MS methods is their relatively long run times, even for food matrices where the speciation is not complex.

Ion-Interaction Chromatography or Ion Pairing: Differences and Novelties

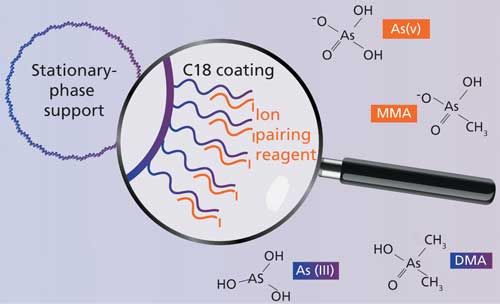

For the food examined in this paper, the number of arsenic compounds quantitated is typically restricted to four species: As3, As5, monomethylarsonic acid (MMA), and dimethylarsinic acid (DMA). These are ionizable compounds, and the LC separation techniques are therefore based on ion-exchange or ion-pair chromatography. The latter is also referred to as ion-interaction chromatography to more correctly denote the wider scope of the interactions encountered beyond formation of ion pairs (5). Nevertheless, Cecchi still titled her book “Ion Pair Chromatography” because of the widespread recognition of the term (5). The term ion-interaction chromatography is emphasized in this article to better highlight the difference in this approach compared to conventional ion-pair chromatography. Some of the pros and cons of ion-exchange and ion-pair chromatography have been summarized earlier (6). Among other factors, ion interaction approaches may use less-expensive columns with well-characterized stationary phases, while methods based on ion exchange may suffer less from matrix interferences.

Ion-interaction chromatography gives great flexibility in tailoring the separation to the speciation analysis in terms of ion-pairing reagents to use for the separation. Whereas ion-exchange separations are based mainly on electrostatic interactions, the retention behavior of analytes in ion-interaction mode may be more complex and involve more than one retention mechanism (5). In addition to electrostatic interaction of analyte ions with the electrical charge imparted by the ion-pairing reagent to the stationary phase, retention may also occur through interaction of uncharged analytes with the nonpolar component of the stationary phase or interaction with residual silanol groups.

Both traditional anion-exchange and anion-pairing methods for the separation of As3, As5, MMA, and DMA use circumneutral or alkaline conditions to ionize most of the target analytes, resulting in run times typically ranging from 9–15 min. Reducing the run time required by anion exchange is still a pressing issue and the subject of recent research (7). The traditional ion-pairing approach for this problem involves anion-pairing reagents, such as tetrabutylammonium hydroxide (8). Our approach investigated here differs in that we use a cation-pairing reagent in a mobile phase at acidic conditions. The purpose of the cation-pairing reagent is not to interact with cations, but rather to repel like charged anions.

It has previously been noted that when working with cation-pairing reagents the separation of early eluted anions or neutral molecules, such as those studied here, can be achieved (9). The problem was, however, that the cationic analytes eluted at long retention times, leading to attempts of combining two ion-pairing reagents in the same solution to shorten the elution times of the analyte cations while trying to maintain the separation of the early eluted species (9). Similarly, Miyashita used a mixture of ion-pairing reagents, with a less effective, shorter-chain cation-pairing reagent to decrease the retention of cations (10). The resulting compromise was, however, not ideal in those cases and was characterized by loss of baseline resolution for some of the early eluted peaks. Reproducibility problems ensued when implementation was attempted in different laboratories, and these techniques did not catch on. The aim of those analyses was to also determine cationic species such as AsC. They, therefore, did not focus on a dedicated optimization for the separation of the early eluted species for situations where cationic species are absent as target analytes. The benefit of the fast run times of the approach explored here was yet untapped.

Ion-Interaction Chromatography: Method Development

To make the output from the column amenable to introduction to the ICP-MS system, we considered in our optimization both peak separation and minimizing the dissolved solids content of the mobile phase. Using the conditions in the study by Miyashita and colleagues (10) as a starting point, we changed the cation-pairing reagent to octane sulfonate (OSA), omitted the anion pairing reagent, retained malonic acid as a buffer, and used the same column. However, the pH, OSA concentration, and malonic acid concentration were reoptimized to separate the four species As3, As5, MMA, and DMA. Furthermore, arsenobetaine was included in the study on the sideline to possibly serve as an internal standard and explore the potential to expand the technique to seafood analysis. Accurate species quantitation in seafood was hindered by the early elution of large amounts of AsB in anion exchange techniques, prompting the development of fast techniques that aim to only quantitate inorganic As in LC runs (11). The late elution of AsB after the other analyte peaks may be an attractive feature here. Proper pH selection is crucial as it is in other ion-pairing or ion-exchange applications. At the experimentally determined optimum pH 4.0, As5 is anionic (pKa1 = 2.3), MMA is mostly deprotonated (pKa1 = 3.6), and As3 (pKa1 = 9.3) and DMA (pKa = 6.2) are neutral (acidity constants taken from reference 12). Thus, the anions arsenate (As5) and MMA are eluted first as a result of electrostatic repulsion from OSA adsorbed onto the C18 surface. The neutral species arsenous acid (As3) and DMA are retained stronger and are eluted later. Retention of those species is likely based on weak partitioning. AsB is zwitterionic at this pH (pKa = 2.2) and is eluted last. Its stronger retention may be influenced by electrostatic attraction between its cationic moiety with the negatively charged stationary phase. In summary, a variety of interaction mechanisms, both attractive and repulsive, take part in the separation. Overall, the limited interaction by attractive forces results in desirable short run times while maintaining baseline separation of the species. Understanding the separation mechanism may be aided by the illustration provided in Figure 1.

Figure 1: Ion interaction chromatography mechanism. Repulsive forces between anions and a negatively charged surface lead to their early elution and separation from neutral molecules, which are weakly retained by partitioning. The diagram includes the four most abundant arsenic species in apple juice and rice.

Analysis of Apple Juice

The regulatory bodies initially focused on the need for testing apple juice, therefore, we first applied our method to the analysis of apple juice.

The analysis was carried out on an Altus-10 HPLC system coupled to a NexION 350D ICP-MS system (both from PerkinElmer). The mobile phase for the apple juice analysis consisted of 2 mM octanesulfonate, 2 mM malonic acid, adjusted to pH 4.0 and blended with 1% methanol. The separation was carried out on a C18 column, monitoring As75 in standard mode. The injection volume was 20 µL. Complete operational details are given elsewhere (13).

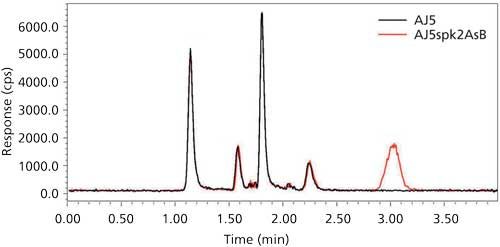

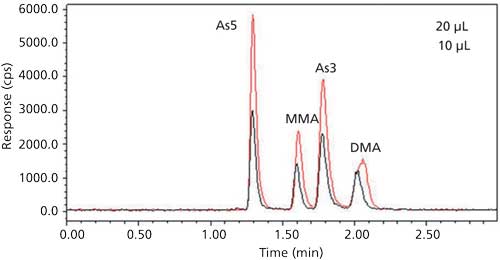

Standards were prepared in mobile phase, and the apple juice samples were injected directly without further dilution. The only sample treatment was filtration, if required. Figure 2 shows the peaks are well resolved. Not only is the run time very short, but also DMA is well resolved from As3, whose adequate separation is typically challenging in anion-exchange chromatography. Furthermore, AsB, which is not present in the samples, is eluted well after the analyte peaks and may be used as an internal standard.

Figure 2: Sample chromatogram of an apple juice sample (20 µL injection) with and without AsB spike. AsB may be used as an internal standard.

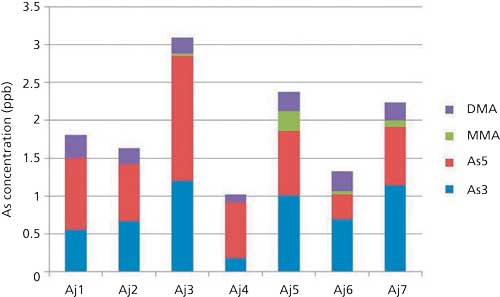

Several store bought apple juice samples were analyzed, and the results (Figure 3) show that both inorganic arsenic forms dominate. Levels of inorganic arsenic are well below the action limit of 10 ppb proposed by the United States Food and Drug Administration (US FDA). The check standards analyzed periodically throughout the run showed 6% maximum deviation over an 8 h period, thus obviating the need for an internal standard.

Figure 3: Apple juice arsenic speciation results.

Arsenic Speciation in Rice: Method Optimization

Arsenic speciation in rice is receiving a lot of attention because of legislation being implemented in Europe and China limiting the content of permissible inorganic arsenic. The most stringent limit of 100 ppb inorganic arsenic applies to rice for production of food for infants and young children.

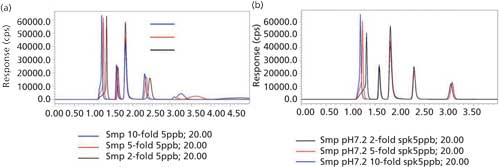

We investigated arsenic speciation in rice after extraction with 0.28 M nitric acid according to the method published by Huang and colleagues (14). This extraction method preserves species identity and has been thoroughly validated (15). Initial tests with direct injection of the acidic extract impacted the chromatography: The DMA peak broadens and shifts to a longer retention time, while the As5 peak shape deteriorated. There is also a very strong effect on AsB retention time and peak shape. Those effects were less pronounced upon dilution, but not eliminated (Figure 4a).

Figure 4: Effect of acidity: Analysis of diluted rice extracts without (a) and with (b) neutralization. Neutralization eliminates adverse effects on DMA and AsB. Solutions were spiked with 5 ppb for all As species. 20-µL injections.

Neutralizing the sample extract restored peak shape and retention times for DMA and also allowed AsB to be used as internal standard (Figure 4b), indicating that the adverse effect on those peaks was caused by the introduced acidity. However, the As5 peak shape remained poor (Figure 4b), suggesting this effect is related to ionic strength. In a subsequent optimization of the mobile phase, we aimed to reduce the difference between sample matrix and mobile phase to improve the As5 peak shape. We obtained both optimum separation and peak shape for all four analyte peaks with the addition of 50 mM ammonium nitrate to the mobile phase. Those experiments were carried out with two-fold diluted, neutralized extract matrix at 10 and 20 µL injection volumes.

The results achieved with neutralization allow for lower detection limits (because of limited sample dilution) and display good method robustness. The benefits of a neutralization step led to its incorporation in the arsenic speciation protocol used by the FDA (16). However, the addition of a neutralization step also increases the analysis complexity and needs more user awareness than a direct analysis of acidic extracts. We therefore tested the possibility of analyzing extracts simply diluted with deionized water without further neutralization. The results show that the improvement to As5 peak shape brought about by the ammonium nitrate addition to the mobile phase persisted, corroborating the earlier indication that the As5 peak shape had been affected by ionic strength differences between samples and mobile phase. However, at low dilutions (twofold), the DMA peak broadened and even split. The effect was seen in both rice extract and extract matrix and persisted when the DMA solution was prepared fresh from the solid chemical, eliminating the possibility that the peak split would be attributable to aging of solutions. Increasing the dilution ratio with deionized water alleviated the issue, and 10-fold diluted extracts were successfully analyzed at 10- and 20-µL injection volumes (Figure 5).

Figure 5: Extract matrix, 10-fold diluted with deionized water, and spiked with 1 ppb As species.

The results of the optimization experiment show that a mobile phase modified by the addition of 50 mM ammonium nitrate provides both good peak separation and peak shape of all four analyte peaks for twofold diluted neutralized extracts and 10-fold diluted extracts without neutralization, allowing flexibility in the sample preparation protocol to accommodate both approaches. If dilution with deionized water is selected as the sole analysis approach, a lower ammonium nitrate concentration in the mobile phase may also be used.

Analysis of Rice Samples

Using the mobile phase composition of the apple juice analysis with the modification of 50 mM ammonium nitrate addition, we injected 10 µL of 1:10 diluted sample extracts. National Institute of Standards and Technology (NIST) 1568b rice flour reference material was digested in duplicate and analyzed to test the applicability of the method for rice analysis. The results agreed well with certified values with recoveries averaging 99% for MMA and DMA, and 97% for inorganic arsenic, thus validating the method.

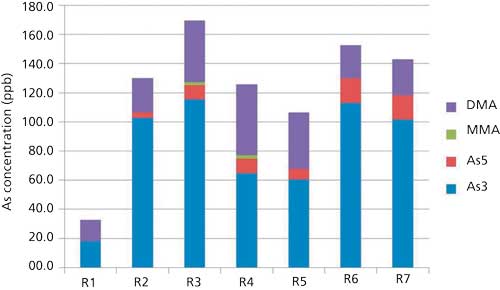

We analyzed two rice samples intended for baby food production and five additional rice-derived products aimed at babies that are 4 or 7 months old. The results are displayed in Figure 6. Inorganic arsenic is given as the sum of As3 and As5. Both species are plotted as adjacent bar segments so inorganic As can be easily read off the graph (Figure 6). The white rice sample (R1) was far below the relevant EU limit of 100 ppb inorganic arsenic, while the brown rice sample (R2) was above the limit. The rice cereal (R3) and porridge samples (R4, R5) range from 67 to 117 ppb, and the two rice cake samples (R6, R7) are 142 and 116 ppb, respectively, both below the total inorganic arsenic limit of 300 ppb set by the EU legislation. Inorganic arsenic was the dominant arsenic form. DMA is the major organic arsenic species, and MMA is a minor constituent of some samples.

Figure 6: Distribution of arsenic species in rice and rice derived products for baby food.

The mobile phase worked as a calibration matrix with species remaining stable during the run. Reanalyzing standards prepared in mobile phase in the range 0.05–5 ppb one day after preparation confirmed the species are stable.

Detection limits expressed as parts per billion in solid were 2.5 µg/kg for As5 and As3 and 2.0 µg/kg for MMA and DMA (expressed on elemental As basis), demonstrating adequate sensitivity of the analysis. Detection limits were calculated based on 3*SD of analysis of seven replicates of a 0.05 ppb As standard. Detection limits may be further lowered by increasing the injection volume from 10 to 20 µL if desired, or by neutralizing samples before injection to utilize lower dilution ratios.

Spike recoveries (1 ppb spike level) ranged from 94–115% for all samples and all species, with averages for all samples being 102%, 104%, 102%, and 102% for As5, MMA, As3, and DMA, respectively.

Summary

An analysis method for arsenic in apple juice and rice by ion-interaction chromatography has been developed that uses electrostatic repulsion of analyte anions from a negatively charged stationary phase in addition to partitioning of neutral analytes. The limited role of attractive forces results in very short run times, substantially shorter than what is currently used for ion-exchange techniques. We adapted the technique for the analysis of apple juice and rice extracts and demonstrated accurate results and method robustness to cope with variations in sample type. Early elution of analyte peaks leads to tall and narrow peaks, which allow lower levels to be measured and increases quantitation accuracy. This approach provides advantages compared to anion-exchange methodology, which not only has longer run times, but also reverses elution order with As5 eluted as the last peak. With substantially shortened run times, recalibrations are much less time consuming (12 min for four standards). Also check standards and quality control solutions can be analyzed more frequently, improving data quality. Furthermore, higher sample throughput is desirable to meet the increased testing needs generated by the introduction of recent legislation for arsenic speciation in food.

References

- K.O. Amayo, A. Raab, E.M. Krupp, and J. Feldmann, Talanta118, 217–223 (2014).

- S. Musil, A.H. Petursdottir, A. Raab, H. Gunnlaugsdottir, E. Krupp, and J. Feldmann, Anal. Chem. 86(2), 993–999 (2014).

- E. Bralatei, S. Lacan, E.M. Krupp, and J. Feldmann, Anal. Chem. 87(22), 11271–11276 (2015)

- M.M. Nearing, I. Koch, and K.J. Reimer, Spectrochim. Acta Part B-Atomic Spectrosc.99, 150–162 (2014).

- T. Cecchi, Ion-Pair Chromatography and Related Techniques (CRC Press, Boca Raton, Florida, 2010).

- K. Neubauer, Spectroscopy24(11), 30–33 (2009).

- B.P. Jackson, J. Anal. At. Spectrom. 30(V), 1405–1407 (2015).

- S. Afton, K. Kubachka, B. Catron, and J.A. Caruso, J. Chromatogr. A1208(1–2), 156–163 (2008).

- X.C. Le, Anal. Chem. 68, 4501–4506 (1996).

- S. Miyashita et al., Chemosphere75(8), 1065–1073 (2009).

- J.J. Sloth, E.H. Larsen, and Y. Julshamn, J. Agric. Food Chem. 53(15), 6011–6018 (2005).

- M. Leermakers et al., Trends Anal. Chem. 25(1), 1–10 (2006).

- H. Ernstberger and K. Neubauer, “Accurate and Rapid Determination of Arsenic Speciation in Apple Juice,” PerkinElmer application note (2015).

- J.-H. Huang, G. Ilgen, and P. Fecher, J. Anal. At. Spectrom. 25, 800–802 (2010).

- J.H. Huang, P. Fecher, G. Ilgen, K.N. Hu, and J. Yang, Food Chem. 130(2), 453–459 (2012).

- K.M. Kubachka, N.V. Shockey, T.A. Hanley, S.D. Conklin, and D.T. Heitkemper. US Food and Drug Administration, “Elemental Analysis Manual for Food and Related Products,” Section 4.11 (FDA, Rockville, Maryland, 2012).

Helmut Ernstberger is with PerkinElmer in Seer Green, UK. Ken Neubauer is with PerkinElmer in Shelton, Connecticut. Direct correspondence to: helmut.ernstberger@perkinelmer.com

Characterizing Plant Polysaccharides Using Size-Exclusion Chromatography

April 4th 2025With green chemistry becoming more standardized, Leena Pitkänen of Aalto University analyzed how useful size-exclusion chromatography (SEC) and asymmetric flow field-flow fractionation (AF4) could be in characterizing plant polysaccharides.

Investigating the Protective Effects of Frankincense Oil on Wound Healing with GC–MS

April 2nd 2025Frankincense essential oil is known for its anti-inflammatory, antioxidant, and therapeutic properties. A recent study investigated the protective effects of the oil in an excision wound model in rats, focusing on oxidative stress reduction, inflammatory cytokine modulation, and caspase-3 regulation; chemical composition of the oil was analyzed using gas chromatography–mass spectrometry (GC–MS).