Time for a Change?

Incognito feels a change is needed.

Photo Credit: Lightspring/Shutterstock.com

Incognito feels a change is needed.

In my experience, analytical chemists seem pretty reluctant to change. I’m certainly exposed to methods and technologies on a fairly regular basis, which I have moved away from or on from a long time ago.

Here I’m thinking of examples from my recent experience such as:

• Using packed gas chromatography (GC) columns

• Not updating older slower methods using 250 × 4.6 mm columns to those using smaller column dimensions and particles

• HPLC columns with larger particles

• Data processing (and here I mean actually calculating the result) using spreadsheets

• Adoption of core–shell HPLC particles

• Not moving to sub-2-µm particle technologies

• High volume sample preparation operations not performed by an automated platform

• Flow splitting in LC coupled to mass spectrometry (MS) (because of large column and higher flow rate combinations)

• Not using GC–MS

• Using trial and error approaches for method development rather than adopting automated or softwareâassisted approaches

I’m sure you have, from time to time, heard about alternatives that gave you a pang of jealousy as these new methods or instruments are so much faster, more convenient, or produce better quality data.

I accept that like any industry or profession, there is a spectrum of “reluctance to change”, ranging from the very early adopters through to the Luddites, but over the past decades, I’ve often made comparisons to casually benchmark our adoption of new technologies either globally or at a local level within the laboratory. My observations would indicate that we do go slower than our counterparts in other industries such as medicine, chemical engineering, information technology, and the like. This is obviously an opinion rather than a verifiable fact, but that’s what I’m employed to do here, and it will be interesting to gauge opinion in the feedback to this column.

Perhaps the important questions to address are: What would make us reluctant to adopt new(er) technologies? Is this reluctance doing our business (or our industry) harm? Can we do anything about it?

Beyond the basic human condition, which defaults to a dislike of change, the factors that tend to be barriers to early adoption of new analytical technology or applications include:

• Business requirements

• Cost

• Resistance to being an early adopter or being risk averse

• Lack of skill or experience to implement new solutions

• Ignorance of the alternatives

• Failure to appreciate the benefits.

I’ve complied this list in a specific order, from those we can do little about to those which are the most reprehensible because they are within our power to change.

The business requirements for analytical support will very often drive the requirement for improvements in our technology. As I commented above, if you work in a research environment then it’s likely that you will appreciate the link between business growth (or survival) and the capability of the business to support the development process. Perhaps intuitively, I’ve always found that R&D pressure tends to be greater in small- to medium-sized enterprises where the focus is much sharper than in larger companies, where several strands of development may be happening simultaneously. However, progress is a two-way street and I’ve always tried to point out to business management what is possible and the benefits that the technology might deliver - in an attempt to be proactive rather than reactive. But ours is, to a large extent, an industry on the tail of the technology curve as we traditional chromatographers would know it, so this in turn dictates the extent to which we can improve our businesses. I can think of several colleagues working in IT who undergo a revolution in their technology on almost a 5-year cycle - something which I cannot relate to in my own working situation.

The cost of change is often a difficult calculation, because the purchase cost needs to be balanced against the opportunity cost and the cost of not implementing the change. Often, however, the obvious cost is an instrument upgrade or purchase. This cost can be mapped on a downward polynomial curve from inception, and the “order” of the polynomial will equate directly with the usefulness, innovation, or capability of the equipment. Few laboratories undertaking GC analysis to any extent are without a benchtop single quadrupole mass spectrometer these days, whereas these were research instruments when I started my career. The adoption curve for UHPLC systems has been rapid and competition strong, therefore the unit cost has reduced significantly as “lower spec” versions are introduced and price becomes a purchasing variable as the number of suppliers proliferates. Orbitrap mass spectrometers were the stuff of fantasy when introduced less than 10 years ago - yet I just visited a University laboratory with 15 of these instruments in their life science department. I see them in client laboratories much more often and see folks eyeing them up for a possible purchase in the future even more frequently.

Opportunity cost is the cost to the business of adopting the new technology, the purchase cost, the disruption while staff transition to new methods and technologies, longer initial lead times on data, the cost of failures because of inexperience, and so on. Aside from the purchase cost, this is largely a management issue, which when properly handled, should not be a barrier to change. However, “disruption” is often cited as a reason to remain with existing technology. It’s more often an excuse for apathy, which is not usually tolerated when the business drivers are high or when competent laboratory management are able to plan well enough to minimize any short-term impact on the production or development schedules.

Being risk-averse with new technology is totally understandable, both from an individual or business culture perspective. Gambles do not always pay off. However, it’s also not good to hang on to the tail of the adoption curve and effectively use this as an excuse to resist change and slow improvements in your capabilities. Watching what your competitors are doing through academic or trade publications, and attending meetings where competitors and collaborators may be speaking can all help to benchmark the adoption and usefulness of new technology and is necessary to stop being left behind.

Not being skilled enough to implement a new solution is, of course, a major barrier, but who decides that this is the case? Invariably the answer is you. The difference between a good analytical chemist and a recipe follower (good though you may be at this) is the ability to research to improve knowledge and to practice to improve skills. Either internally or externally within your business there will be resources to help you to be able to successfully operate a new instrument or to try out a new sample protocol or adopt a new analytical method, but you have to want to do it and be open to the idea of change. Of course, waiting to adopt new technology or different methods until others have done it is a lot safer (and cost-effective), but it won’t push your analytical capabilities ahead of the envelope and help to differentiate your business. It comes down to your attitudes to change and your reluctance to improve.

The last two points in the list can be tackled together, and relate directly to your willingness to seek improvement, to look around and engage with the literature and the wider community within your industry to appreciate what is happening. For this you need to read widely, talk with colleagues, collaborators (including vendors and suppliers), and competitors, and to attend meetings and conferences. I’m not going to dwell on these final two because they are very intuitive, except to ask you to consider one aspect. I often hear that making improvements, adopting new methods, hardware, or software is “way above my pay grade”. Is it? If you really believe that this is the case, then I postulate that it will always remain so.

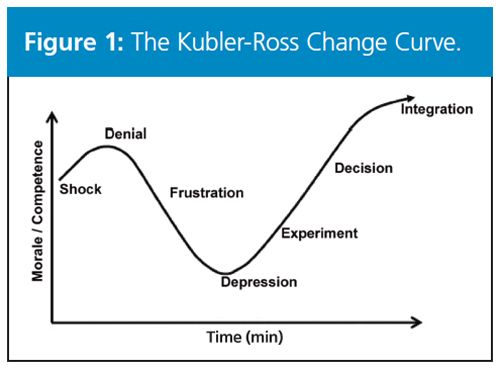

For those who wish to overcome their resistance to change. I’ve included a “selfâhelp” figure to explain the Kubler-Ross Change Curve, so that you can reconcile your emotions or attitudes with the various stages of change (see Figure 1).

The area at the minima around “Depression” is sometimes known as the “Well of Despair”. This is not exactly a cheery description, but the curve as a whole can help to explain the various stages that you might go through and help you to recognize what may be necessary to overcome resistance and get onto the upslope of experimentation, making decisions to change and then integrating the new technology or methodology into your work.

Are you facing a change right now? Where are you on the curve and how can you best move onto the “upslope”?

A Final Word from Incognito—The Past, Present, and Future of Chromatography

February 10th 2022After 14 years in print, Incognito’s last article takes a look at what has changed over a career in chromatography, but it predominantly focuses on what the future might hold in terms of theory, technology, and working practices.

Sweating the Small Stuff—Are You Sure You Are Using Your Pipette Properly?

October 7th 2021Most analytical chemists believe their pipetting technique is infallible, but few of us are actually following all of the recommendations within the relevant guidance. Incognito investigates good pipetting practice and busts some of the urban myths behind what is probably the most widely used analytical tool.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)