Thin Layer Chromatography

Thin layer chromatography (TLC) is a planar chromatographic technique introduced in the 1950s as a fast, easy and inexpensive method for qualitative analysis.

Thin layer chromatography (TLC) is a planar chromatographic technique introduced in the 1950s as a fast, easy and inexpensive method for qualitative analysis. Just as with column chromatography, the chemistry and size of the particles (as well as the thickness of the layer) affects the speed and nature of the separations that are possible. After the sample is applied near one edge, the plate is developed by dipping the edge into solvent and allowing the separation to take place. Once the process nears completion, the plate is dried and various methods can be used to derive qualitative and quantitative measurements from the plate. These methods include densitometry, fluorometry, and even mass spectrometry.

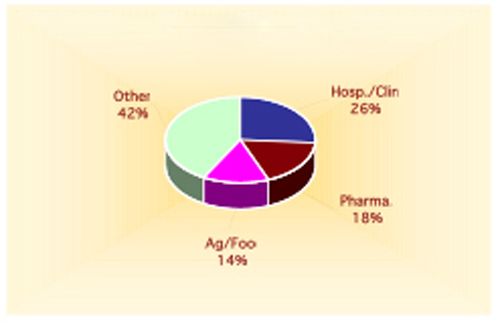

2006 Thin Layer Chromatography Industrial Demand

The three main industrial applications for thin layer chromatography are in clinical, pharmaceutical and food testing. Combined, these three industries represent nearly 60% of the total demand for TLC. One of the most common specific types of clinical tests performed with TLC is for the presence of drugs of abuse. In the pharmaceutical industry, TLC is widely used in production and quality assurance applications. The presence or absence of substances can be determined qualitatively, while quantitative tests can determine the purity of a drug sample. Within the food industry, TLC is used for many different applications, ranging from lipid separation to food dye analysis.

Although TLC can be fully automated, it is commonly a manual technique. Consequently, aftermarket supplies and consumables dominate the market: reagents, standardized plates and capillary tubes for sample application. Altogether, such items account for majority of the total market. TLC faces competition from HPLC and, particularly in the pharmaceutical industry, flash chromatography.

The foregoing data was extracted and adapted from SDi's Global Assessment Report, 9th Edition. For more information, contact Glenn Cudiamat, VP of Research Services, Strategic Directions International, Inc., 6242 Westchester Parkway, Suite 100, Los Angeles, CA 90045, (310) 641-4982, fax: (310) 641-8851, e-mail: cudiamat@strategic-directions.com

Regulatory Deadlines and Supply Chain Challenges Take Center Stage in Nitrosamine Discussion

April 10th 2025During an LCGC International peer exchange, Aloka Srinivasan, Mayank Bhanti, and Amber Burch discussed the regulatory deadlines and supply chain challenges that come with nitrosamine analysis.