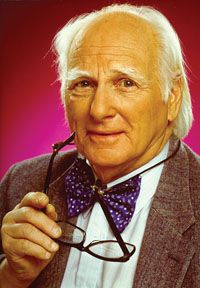

Remembering Walt Jennings

We note with sadness the passing of pioneering American gas chromatographer Walter G. Jennings on 5 July 2012. Walt, as he preferred, died peacefully at home surrounded by family. He was 90 years old.

We note with sadness the passing of pioneering American gas chromatographer Walter G. Jennings on 5 July 2012. Walt, as he preferred, died peacefully at home surrounded by family. He was 90 years old.

Walt was known as a tireless researcher, innovator, entrepreneur and teacher who, while at the University of California at Davis and throughout his long career, was a strong advocate of gas chromatography (GC) and its use as a practical tool for solving many problems in a wide range of scientific areas. Although his academic and business accomplishments are significant, he is best known for the relationships he made with the scientists and colleagues he touched as a teacher, collaborator and mentor who supported investigators with his experience, thought-provoking instruction, helpful advice and encouragement.

Walt achieved a bachelor’s degree in dairy science in 1950, a master’s degree in 1952 and a PhD in 1954. His initial areas of research were in chemical sanitation efficiency and kinetics associated with food processing equipment, but Walt’s interest in flavour chemistry became a driving force to develop new technologies to unravel the chemical composition of flavour. He quickly came to understand the role that GC could play in this research, and his team successfully identified the critical flavour components in the Bartlett pear, which was a significant accomplishment in 1965. With support from the US Department of Agriculture, he built the first GC system at the university in 1955.

Over the next 20 years there was a continuous string of innovations, including developments in carbon dioxide extraction, inlet liner technology, ferrule technology and column and phase technology. During a visit to Europe in the late 1960s, Walt was exposed to glass capillary chromatography and he instantly realized its potential. On his way home from Europe he made a side trip to purchase and bring home one of Klaus Hupe’s earliest glass-drawing machines. Immediately, his team in Davis began drawing tubing and developing excellence in capillary GC and column making. Capillary columns were in great demand from forward-thinking chromatographers and the columns from Walt’s Davis lab were much sought after in the US.

In 1974, Walt and a graduating student, Rob Wohleb, founded J&W Scientific, manufacturing capillary GC columns from a garage. The company became quite successful and began innovating in the field of column technology, developing chemically bonded stationary phases, improving deactivation and developing a range of phases that are the standards in the industry today.

Walt was a productive researcher with more than 200 publications in the GC field including eight books and several book chapters. His books Gas Chromatography with Glass Capillary Columns (Academic Press, 1978) and Analytical Gas Chromatography (Academic Press, 1997) are considered classics in the field.

This story originally appeared in The Column. Click here to view that issue.

Regulatory Deadlines and Supply Chain Challenges Take Center Stage in Nitrosamine Discussion

April 10th 2025During an LCGC International peer exchange, Aloka Srinivasan, Mayank Bhanti, and Amber Burch discussed the regulatory deadlines and supply chain challenges that come with nitrosamine analysis.