Quantitative Analysis of Carbonyl-DNPH Derivatives by UHPLC–UV

The Application Notebook

Thermo Fisher Scientific Application Note

Terry Zhang and Guifeng Jiang, Thermo Fisher Scientific, San Jose, California, USA.

Introduction

Carbonyl compounds from motor vehicle and industrial emissions, precursors to ground-level ozone, are also sources of pollution in indoor living and working environments.

HPLC coupled with UV detection is the most widely recognized technique for the analysis of carbonyl-DNPH derivatives.

Instrumentation/equipment

LC separations were performed on a Thermo Scientific Accela 1250 UHPLC system which offers the flexibility of performing both HPLC and UHPLC separations on a single platform. The Accela 1250 Pump delivers precise flows and accurate gradients at an expansive range of flow rates (up to 2 mL/min) and pressures (up to 1250 bar); and accelerates method development and maximizes method flexibility through quaternary gradient capabilities. The Accela UHPLC system together with Thermo Scientific 1.9 μm Hypersil GOLD C18 columns enables fast chromatographic separations with high efficiency and resolution.

The use of sub-2 μm particle columns facilitates rapid analysis of challenging samples by improving chromatographic resolution, speed and sensitivity. Using the Accela 1250 UHPLC system, a single Hypersil GOLD C18 column (1.9 μm, 2.1 × 100 mm) and a simple acetonitrile/water gradient, a mixture of the DNPH standards of 12 carbonyls targeted by US EPA Method 8315A Procedure 1 was successfully separated. This analysis was performed using a flow rate of 800 μL/minute, which generated back pressures over 1000 bar. The Accela 1250 pump is the only commercially available LC platform that is capable of handling such high operational pressures due to its very low internal back pressures.

Results

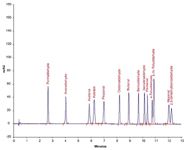

Figure 1 demonstrates UHPLC separation of the 15 carbonyl-DNPH derivatives using the Hypersil GOLD C18 column and a 13-minute gradient. All compounds but the tolualdehyde isomers were baseline resolved.

Figure 1: UHPLC separation of 15 carbonyl-DNPH derivatives at 20 μg/mL concentrations using a Hypersil GOLD C18 column and 13-minute gradient.

Excellent linearity in detector response was observed over the range of 98–50000 ng/mL (ppb) [196–100000 ng/mL (ppb) for m- and p-tolualdehyde combined], with correlation coefficients greater than 0.999 for all analytes.

Reproducibility and Accuracy

Reproducibility was investigated by analysing five replicate injections of each analyte. With four channel mixings of the solvents at various viscosities, retention time RSDs ranged from 0.52–2.22% while peak area RSDs ranged from 0.46–4.91%, indicating excellent method reproducibility, particularly of the LC pump.

Quantitative accuracy for all carbonyl-DNPH derivatives was evaluated at two levels of concentrations, 400 ppb and 2000 ppb, using external calibration method. The accuracy of two representative analytes, benzaldehyde-DNPH and o-tolualdehyde-DNPH are reflected by the values of 96.3% and 103.6% at 400 ppb, respectively, and 99.8% and 99.9% at 2000 ppb, respectively and achieved with the UHPLC method.

Conclusion

- The Accela 1250 UHPLC system offers the flexibility of performing both HPLC and UHPLC separations. With its very low internal back pressure, this system is capable of operational pressures up to 1250 bar, which is significantly higher compared to other commercial UHPLC systems.

- The Accela 1250 UHPLC system coupled with sub-2 μm Hypersil GOLD columns enabled highly efficient and reproducible separations of carbonyl-DNPH derivatives.

- Fast, accurate and robust quantitative analysis of low molecular weight carbonyls at ppb levels was achieved using Accela 1250 UHPLC followed by UV detection.

- UHPLC significantly improves resolution and speed of analysis and provides a powerful alternative to the HPLC-based procedures currently recommended by regulatory agencies for environmental monitoring of carbonyls.

Thermo Fisher Scientific Inc.

355 River Oaks Parkway, San Jose, California 95134, USA

tel. +1 561 688 8900 fax +1 608 273 6880

E-mail: analyze@thermoscientific.com

Website: www.thermoscientific.com

Altering Capillary Gas Chromatography Systems Using Silicon Pneumatic Microvalves

May 5th 2025Many multi-column gas chromatography systems use two-position multi-port switching valves, which can suffer from delays in valve switching. Shimadzu researchers aimed to create a new sampling and switching module for these systems.

Studying Cyclodextrins with UHPLC-MS/MS

May 5th 2025Saba Aslani from the University of Texas at Arlington spoke to LCGC International about a collaborative project with Northwestern University, the University of Hong Kong, and BioTools, Inc., investigating mirror-image cyclodextrins using ultra-high performance liquid chromatography–tandem mass spectrometry (UHPLC–MS/MS) and vibrational circular dichroism (VCD).

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)