The Origins of GC Carrier Gases: Putting a Genie in the Bottle

This month's instalment tracks the progress of helium, hydrogen, and nitrogen carrier gases as they start their journey through a GC system.

Have you wondered how the gas chromatography (GC) carrier gases helium, hydrogen, argon, and nitrogen are transformed from their natural conditions or precursors into highly purified compressed states inside laboratory gas cylinders or generators? Here, we track the genesis of the top four carrier gases before they start their journey through a GC system.

Unlike liquid chromatographers, gas chromatographers have only a few mobile phases to apply to their separations. The mobile phase in liquid chromatography (LC) plays an active role in determining solutes' retention characteristics, and it does so in relation to the chemical nature of the stationary phase. To that end, liquid chromatographers employ various solvents, solvent mixtures and gradients, buffers, and other additives in combination with a wide array of stationary phase modes and types that give them degrees of control over their separations that the rest of us might dream of.

In gas chromatography (GC) the situation is much more limited. The role of the GC mobile phase is reduced to simply carrying solute molecules along the column while they are not dissolved in or adsorbed on the stationary phase. All of a GC separation's selectivity can be attributed to the stationary phase alone. The GC mobile-phase job description of "inert" and "carrier" gas sounds about as dull as it can be. And also unlike in LC, GC carrier gases come with some nonintuitive behaviours that can be daunting to understand at first, such as the effects of gas compressibility on flow and separation. These side effects of a gaseous mobile phase have been dealt with in innumerable publications and discussions, and I won't go into them any further in this article. Also, for space reasons the use of carbon dioxide for supercritical fluid chromatography (SFC) will not be addressed in any detail.

This month's instalment asks the following question: Where exactly do the various GC carrier gases come from? The obvious and wrong answer is, "from a gas cylinder". Instead, consider the elemental or natural states of the primary carrier gases helium, nitrogen, hydrogen, and argon. Some of these are quite common in nature; others are rare. How are the carrier gases obtained from nature and purified to better than 99.9999%?

Natural Occurrence

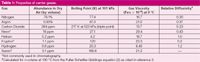

Table 1 lists gases that have been used — or at least could be used — for GC mobile-phase duty. The second column of Table 1 lists their average concentrations in the natural atmosphere at sea level. Nitrogen is, of course, the most abundant gas with a 78.1% portion. It is followed by oxygen at 20.9%, although pure oxygen is omitted from the table since it makes a decidedly poor and chemically active carrier gas. Purified air, however, has been used as a carrier gas in certain limited situations such as with some portable gas chromatographs and at limited low column-oven temperatures.

Table 1: Properties of carrier gases.

Argon is the next most abundant atmospheric carrier gas, followed by carbon dioxide as used for SFC. The carbon dioxide level in Table 1 is the reported monthly mean value at Mauna Loa in Hawaii as of October 2013 (1). The trace gases neon, helium, krypton, hydrogen, and xenon, which taken together account for about 25 ppm of the atmosphere's content, are listed below carbon dioxide. Krypton and xenon are and will remain too expensive to be taken seriously as GC carrier gases, but it is possible that desperate gas chromatographers with no helium on hand may have tried one of the noble gases if they could find a cylinder. Neon seems like a logical candidate. If helium prices continue to increase then perhaps neon, which costs more than five times the price of helium, will become another helium replacement like hydrogen.

Beyond simple cost considerations, there are performance reasons to prefer certain carrier gases. Hydrogen, for example, is sometimes preferred because of its low viscosity and high diffusivity. The low viscosity means that less pressure is required to attain any particular flow rate with hydrogen, which translates to better performance at higher flows and with narrower-bore columns. Higher diffusivity produces more efficient separations around the optimum carrier gas velocity region. Neon, on the other hand, has high viscosity and low diffusivity, which make it less attractive.

Helium, a nearly nonrenewable natural resource, is light enough that, along with hydrogen, it attains escape velocity after it is released into the atmosphere and simply leaks off into space where it is swept away by solar wind. Not that these elements are scarce — by some accounts hydrogen comprises 73.9% of the known baryonic matter in the universe, followed by helium at 24%. Both are replaced in the Earth's atmosphere at slow rates; the balance between replenishment and loss accounts for their average natural concentrations in air shown in Table 1. A chromatography laboratory with helium carrier gas in use would be above average — aren't they all — with a considerably higher background helium level. It's the higher levels of hydrogen in the laboratory that are of real concern and that drive the installation of hydrogen detectors and better laboratory ventilation.

Sourcing, Separation, and Purification

Most carrier gases come from natural sources. Hydrogen is the exception. The hydrogen supplied in pressurized tanks is most often obtained as the by-product of other commercial reactions and processes. Laboratory generation of hydrogen uses electrolysis of water, and hydrogen is the only carrier gas that is truly generated in the laboratory. A laboratory nitrogen generator does not actually generate nitrogen, it just separates and purifies nitrogen from an incoming air stream. Helium, as the reader must know, is a story unto itself. Helium is a natural resource that is not replenished at anything near its rate of consumption — it is irreplaceable. Helium and hydrogen are discussed in their own sections below.

Nitrogen and argon are also obtained from natural sources for industrial and laboratory applications, but the available quantities are not in any danger of depletion. They are both produced in large quantity by separation from air and then further purified until the desired GC grade is obtained. Commercial air separation plants also produce oxygen and can yield neon, krypton, and xenon. There are three types of air separation generally in use today. Cryogenic fractionation is the most familiar first step along the route to pure nitrogen and argon carrier gases.

Cryogenic Fractionation: In cryogenic fractionation for recovery of nitrogen, argon, and oxygen, ambient air is first filtered and pressurized. Condensed water is removed, and then the air stream is further dried and hydrocarbons plus carbon dioxide are removed by active adsorbent beds such as molecular sieves. The purified air is cooled until it liquefies, and then the oxygen and argon are fractionally distilled from the nitrogen. Neon, krypton, and xenon can be separated as well by applying additional fractionation steps. The resulting purified gas streams are stored in a liquid state or in a gaseous state as industrial-purity bulk gases.

Typically, the initial cryogenic fractionation process yields nitrogen purities around 99.95%. Further purification is required to bring the gas up to ultrahigh purity or research grade for service as a GC carrier gas or for other specialty gas services. Additional fractionation steps, as well as pressure-swing adsorption, can be used.

Pressure-Swing Adsorption: Pressure-swing adsorption (PSA) is a smaller scale air-separation technique that is used at the industrial level when the size and cost of a cryogenic plant is not practical or necessary. PSA purification is also found in some laboratory nitrogen generators. PSA works by passing air through initial filters that remove particles, hydrocarbons, and the bulk of the water. Next, the cleaned air passes through a carbon-sieve bed at elevated pressure, where oxygen plus residual water and carbon dioxide are adsorbed while purified nitrogen flows through. As the bed approaches saturation, the incoming air flow is switched to a second filter bed, while the pressure in the first is reduced to release the trapped oxygen and impurities into an exhaust air stream. The oxygen-enriched air can be recovered — for example, for use in portable oxygen supplies. The two filter beds are used alternately to give a continuous flow of purified nitrogen. The final nitrogen purity is controlled by flow rate, the size of the adsorbent beds, the use of multiple PSA stages, and filtration (4). PSA can produce nitrogen output with a purity as high as 99.9995%, which is suitable for many GC applications.

Membrane Separation: If moderately pure nitrogen in the range of 95% to 99.5% pure is suitable for an application then purification by selective membrane permeation may be an option. Filtered pressurized air is fed into one or more hollow-tube membrane separators, from which purified nitrogen emerges in the main flow stream and the impurities — including oxygen, water, and carbon dioxide — are taken off in a separate stream. In a nitrogen separator the membrane has permeation and mechanical characteristics that selectively permit impurities to pass through while blocking nitrogen. The ultimate nitrogen purity depends on the number and type of membranes used. Generally a membrane separator alone will not yield sufficiently pure nitrogen for GC carrier gas purposes.

Helium: Helium has become expensive and difficult to obtain in recent years. Anyone who has had to purchase and manage helium supplies has experienced this first-hand. The reasons for this change include increasing demand for applications such as superconducting magnets for magnetic resonance imaging (MRI) as well as for military applications. At the same time the available supply of helium in the United States has shrunk, because of difficulties with distribution and the imminent closure of the diminishing National Helium Reserve. Today, however, it appears that the shutdown is delayed. Other factors make helium's future look bleak, including the slow shift to shale natural gas sources that contain no helium, and a lack of incentive for natural gas producers to bring new helium separation facilities on line. There is some hope for a loosening of the worldwide helium supply with the opening this year of significant additional helium production facilities in Qatar and the continuing demand from existing supplies in Africa and China.

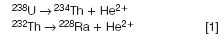

Helium is generated naturally in the earth's crust primarily as the by-product of uranium and thorium radioactive alpha decay processes that start with the stable naturally occurring isotopes 238U (half-life 4.5 × 109 years) and 232Th (half-life 1.1 × 1010 years):

Additional decay processes yield more alpha and other nuclear particles until the decay chains end at lead. The alpha particles (He2+) recombine with electrons and form helium upon impacting nearby minerals. Clearly, in-house generation of helium is not a possibility, although some have quipped that it might be possible with a self-sustaining fusion reactor; clearly not an imminent source. It is possible to recover small amounts of helium from cryogenic air separation processes, but the cost is considerably more than obtaining helium from natural gas. The total amount of helium that could be recovered by atmospheric fractionation would not make much of an impact on the worldwide demand.

The total amount of terrestrial helium generated by natural radioactive decay has been estimated at about 3000 metric tons annually (5). The helium thus formed remains entrained in impervious rock, but it is released through fissured rock to collect in gas pockets along with other natural gases. The resulting helium concentrations in natural gas can range from a few parts-per-million up to as high as 7%. Helium is separated from natural gas by liquefaction of the other gases including nitrogen, methane, and carbon dioxide, followed by fractional distillation of the still-gaseous helium. Like other industrial gases, helium is further purified to reach laboratory research purities suitable for GC.

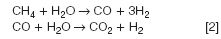

Hydrogen: Naturally occurring hydrogen molecules are found only at low concentrations in the atmosphere — free hydrogen escapes the same way as helium. Fortunately, and unlike helium, hydrogen is easily synthesized by industrial steam reformation of natural gas:

Other industrial reaction pathways to hydrogen also exist. Hydrogen has received considerably more attention in recent years because of a popular resurgence as a transportation fuel. Perhaps some day gas chromatographers will be able to tap into their automobiles for a field supply of carrier gas.

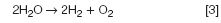

In the laboratory, hydrogen is produced via electrolysis of water:

Water-to-hydrogen oxidation–reduction can be carried out in a number of ways. Modern laboratory hydrogen generators use a proton-exchange membrane (PEM) that passes protons (H+) for recombination into hydrogen molecules while being impermeable to the gaseous hydrogen and oxygen reaction products. The hydrogen is then passed through a platinum membrane that blocks all other molecules and attains a hydrogen purity of six nines or better. The oxygen is vented.

Gas chromatographers who have run their fused-silica columns with hydrogen at elevated temperatures have, perhaps unwittingly, performed membrane purification of their carrier gas right through the column walls. Fused silica is hydrogen-permeable at the high end of GC oven temperatures, above about 320 °C. It is not difficult to observe that the net flow rate through the column becomes less than the mass flow rate entering the column by measuring the average carrier gas velocity as temperatures increase (6). A significant portion of the hydrogen carrier is lost through the column walls, especially for smaller diameter columns. The actual average velocity has to be measured by timing an unretained peak — simply reading the electronic pressure control (EPC) system reported value won't be accurate because EPC does not compensate for this effect.

Conclusion

GC carrier gases traverse varied and complex paths on their way to the gas tanks and generators that sometimes are taken for granted in the laboratory. Some carrier gases, such as nitrogen and argon, are sourced from the atmosphere, whereas helium is a nonrenewable natural resource found primarily in natural gas. Hydrogen is the only carrier gas that is synthesized, either on-demand in laboratory gas generators or as a by-product of industrial chemical processes. All of the carrier gases must be purified substantially and multiple times to attain the levels required for GC.

The next "GC Connections" instalment will address the storage and use of both carrier and other GC gases, and the multiple steps by which pressures and flows are controlled on the way to a GC inlet.

John V. Hinshaw is a senior scientist at Serveron Corporation in Beaverton, Oregon, USA, and is a member of the LCGC Europe editorial advisory board. Direct correspondence about this column should be addressed to "GC Connections", LCGC Europe, 4A Bridgegate Pavilion, Chester Business Park, Chester, CH4 9QH, UK, or email the editor-in-chief, Alasdair Matheson, at amatheson@advanstar.com

References

(1) U.S. Commerce, National Oceanic and Atmospheric Administration, Earth System Research Laboratory, Global Monitoring Division, "Trends in Atmospheric Carbon Dioxide," retrieved November 2013 from http://www.esrl.noaa.gov/gmd/ccgg/trends/#mlo.

(2) E.N. Fuller, P.F. Schettler, and J.C. Giddings, Ind. Eng. Chem. 58, 19–27 (1966).

(3) L.S. Ettre and J.V. Hinshaw, Basic Relationships of Gas Chromatography (Advanstar, Cleveland, Ohio, USA, 1993), pp. 44–47.

(4) S. Ivanova and R. Lewis, CEP Magazine, 38–41 (June 2012).

(5) M.A. Cook, Nature 179(4552), 213 (1959).

(6) J.E. Cahill and D.H. Tracy, J. High Resolut. Chromatogr. 21, 531–538 (1998).

New TRC Facility Accelerates Innovation and Delivery

April 25th 2025We’ve expanded our capabilities with a state-of-the-art, 200,000 sq ft TRC facility in Toronto, completed in 2024 and staffed by over 100 PhD- and MSc-level scientists. This investment enables the development of more innovative compounds, a broader catalogue and custom offering, and streamlined operations for faster delivery. • Our extensive range of over 100,000 high-quality research chemicals—including APIs, metabolites, and impurities in both native and stable isotope-labelled forms—provides essential tools for uncovering molecular disease mechanisms and exploring new opportunities for therapeutic intervention.

New Guide: Characterising Impurity Standards – What Defines “Good Enough?”

April 25th 2025Impurity reference standards (IRSs) are essential for accurately identifying and quantifying impurities in pharmaceutical development and manufacturing. Yet, with limited regulatory guidance on how much characterisation is truly required for different applications, selecting the right standard can be challenging. To help, LGC has developed a new interactive multimedia guide, packed with expert insights to support your decision-making and give you greater confidence when choosing the right IRS for your specific needs.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)