New Chromatography Columns and Accessories at Pittcon 2013 Part II

LCGC North America

This month's installment of "Column Watch" comprises Part II of our yearly report on new products introduced at Pittcon. Gas chromatography columns, sample preparation products, and hardware, accessories, and small tabletop instruments mainly for sample preparation are covered.

This month's installment of "Column Watch" comprises Part II of our yearly report on new products introduced at Pittcon. Gas chromatography columns, sample preparation products, and hardware, accessories, and small tabletop instruments mainly for sample preparation are covered.

The Pittcon 2013 Conference and Expo (less formally known as the 64th Pittsburgh Conference on Analytical Chemistry and Applied Spectroscopy) was held for the first time in the city of Philadelphia, Pennsylvania, on March 17–21, 2013. This year's event hosted over 1011 instrument manufacturers and laboratory suppliers in more than 1925 booths. In addition to attending the exposition, the conferees listened to more than 2200 technical presentations (orals, posters, workshops, invited and contributed talks, and award symposia), checked on numerous company seminar rooms, or attended one of 100 short courses.

Although the attendance was slightly up this year compared to last year, the average attendance had been shrinking over the past several years. Still, Pittcon remains one of the most important international analytical exhibitions where companies introduce their latest instruments, instrument accessories, software, columns, and sample preparation and other consumable products. Several notable companies were missing again this year, but enough were present such that visitors had plenty of opportunities to investigate new (and old) technologies.

The purpose of this report is to provide information about many of the new separation consumables and accessory products that were displayed at Pittcon 2013. In some cases, products that were introduced during 2012 but after Pittcon 2012 (1,2) may be included for reasons of completeness. The information is based on manufacturers' responses to a questionnaire mailed in early 2013. Because of space limitations and the fact that some manufacturers did not respond to the questionnaire, this report cannot be considered a comprehensive listing of all new products that were introduced in Philadelphia. However, over the years, these Pittcon introduction summaries have provided a good source of information that would be difficult for one individual to gather during the four days of the exhibition. In addition, the products introduced have shown definite correlations to current research, development, and application activity in the separation sciences.

As in previous years, columns and other products recommended by their manufacturers primarily for biomolecule separations or sample preparation are denoted in the tables with the designation BIO. Some of these products may be used for general high performance liquid chromatography (HPLC) separations as well, but their main emphasis is for biological samples.

In part I of this coverage (3), I described new column introductions in the areas of HPLC, reversed-phase LC, normal- and bonded-phase LC, hydrophilic interaction liquid chromatography (HILIC), supercritical fluid chromatography (SFC), ion-exchange and ion chromatography, size-exclusion chromatography (SEC), and specialty chromatography. In this installment, I will look at gas chromatography (GC) columns, sample preparation products, and hardware, accessories, and small tabletop instruments, mainly for sample preparation.

Trends and Highlights

General: This year, I observed that there was a continuing trend in high-efficiency chromatography driven by dramatic increases in chromatographic efficiency, especially in HPLC or ultrahigh-pressure liquid chromatography (UHPLC). In addition, the introduction of more products with inert surfaces driven by instrumental increases in sensitivity especially through increasing use of tandem mass spectrometry (MS) techniques in both GC and LC. The development of systems with more inert flow paths including more PEEK-lined tubing, newer deactivated packing materials, deactivated surfaces such as fused-silica columns, vials, metal tubing, and GC injection liners are all being addressed to improve recovery of very low levels of analytes.

In HPLC, there was a further increase for instrumental enhancements, hardware components, and accessories designed to work with UHPLC. Many application-specific columns for HPLC and GC that are tested with "real world" samples before shipment were noted. Again at Pittcon, a considerable number of new accessories, hardware, and devices were introduced that are designed to make the chromatographic laboratory more productive.

HPLC Columns: Overall, there were no real breakthroughs in HPLC column technology, but a refinement in particle sizes, stationary-phase technologies, and column dimensions was noted. Pittcon 2013 saw the introduction of a few more sub-2-µm columns for UHPLC, but not to the extent of several years ago. However, many new superficially porous particles (SPP, also known as core–shell particles), both particle sizes and phases, made their appearance including particles with diameters as small as 1.3 µm. UHPLC has now established itself as a viable solution to today's separation problems; at least nine major instrument vendors now address this market with instruments capable of operation at pressures as high as 19,000 psi. This year a few more HILIC columns appeared, but alternative reversed-phase selectivities, especially phenyl-hexyl and penta-fluorophenyl phases, were evident at the booths of a number of column companies. Still, in the number of introductions, reversed-phase HPLC maintained its dominance. Application-wise, chiral, protein (particularly monoclonal antibody columns), and ion chromatography or ion-exchange columns dominated.

Gas Chromatography: GC column introductions were dominated by new stationary phases, especially with new levels of inertness. However, chromatographers in the food, environmental, and forensic areas are finding that there is more than column inertness that must be addressed. Thus, ultra-inert total flow systems are under development, driven by the increased sensitivity of mass spectrometers. Porous layer open tubular (PLOT) columns with built-in particle traps to capture any tiny solid phases flaking off the columns made their appearance. Specifically, chiral compounds, polycyclic aromatic hydrocarbons (PAHs), volatile organic compounds (VOCs), semivolatiles, and fatty acid analyses were addressed in the applications' domain. A new polar ionic liquid column with much higher temperature capability than typical wax columns was shown for the first time.

Sample Preparation: Sample preparation products for automation, such as 96-well filtration and solid-phase extraction (SPE) plates and plate seals and SPE micropipette tips, seemed to be in vogue. Because of the popularity of protein-crash approaches for the analysis of drugs and metabolites in biological fluids, filters (96-well plates and single tubes) designed to remove both precipitated protein and lipids or phospholipids were introduced. Affinity SPE phases for proteins and aflatoxins as well as a family of mycotoxins removal cartridges were noted. QuEChERS (quick, easy, cheap, effective, rugged, and safe; pronounced "catchers") is still "catching on" as the favored sample preparation technique for pesticides in fruits and vegetables. Some interesting phase separation columns might bring renewed interest to liquid–liquid extraction (LLE).

Accessories: More than 40 new hardware products, accessories, and benchtop instruments for LC, GC, and sample preparation were noted. This year I broke the hardware and accessories introductions from the benchtop instrumental introductions into two separate tables (see Tables III and IV). UHPLC-specific products (tubing, fittings, column hardware, and in-line filters) with higher pressure ratings and decreased dead volumes were introduced. Several automated sample preparation instruments contribute to minimize the labor-intensiveness and drudgery of manually preparing samples for chromatography were introduced by smaller instrument vendors. This year a number of workstations that do some (but not all) of the sample preparation steps were evident. Products for preparing solid materials for further workup included homogenizers, shakers, and solvent evaporation stations. A unique sample card for direct analysis in real time (DART) MS was introduced that did away with lengthy sample preparation steps.

Gas Chromatography Columns

Although GC is considered a relatively mature separation technique, new GC columns continue to be introduced each year at Pittcon (Table I). This year saw the introduction of 11 new GC columns: nine wall-coated open tubular (WCOT) and two PLOT. These columns were introduced by seven different vendors.

Table I: Gas chromatography columns

Applications-specific GC columns are always popular introductions at Pittcon. This year most of the column introductions were focused on specific applications. In the area of environmental, capillary columns for volatile organic compounds (as designated in the US EPA Methods 501, 601, and 624) and semivolatiles (EPA 525, 610, 625, 8100, and 8270D) were featured. As GC detectors, particularly mass spectrometers, become more sensitive, GC columns have had to keep up with the demand of more inertness but now users are demanding more inertness in other parts of the system from the injector to the detector, which puts pressure on the manufacturers to keep up with these market demands. So, now the inertness of the entire flow path is being questioned and liners, seals, tubing, fabricated parts, and so on are being deactivated by special treatment processes.

Another application area that received attention was the analysis of polynuclear aromatic compounds in foods; two new columns were introduced that addressed this area. Polycyclic aromatic hydrocarbons (PAHs) are primarily formed by incomplete combustion or pyrolysis of organic matter and during various industrial processes. PAHs generally occur in complex mixtures which may consist of hundreds of compounds. Humans are exposed to PAHs by various pathways. While for non-smokers the major route of exposure is consumption of food, for smokers the contribution from smoking may be significant. Food can be contaminated from environmental sources, industrial food processing, and from certain home cooking practices. There are 15 PAHs that are on the European Food Safety Authority's (EFSA) list and 25 on the expanded US EPA list (Method 610), but many more potentially carcinogenic compounds may also contribute to human health. Since the larger fused ring PAHs are rather nonvolatile, higher temperatures are needed to elute them in a reasonable timeframe. In fact, in some cases, reversed-phase HPLC can do a better job but sometimes sensitivity issues arise (4).

Chiral compounds are most often separated by HPLC, but for essential oils that are complex and volatile a new chiral column was introduced that allows enantiomeric separations without requiring undesirable derivatizations. Fatty acid methyl ester (FAMEs) analyses have been a mainstay for GC for years; a new capillary column that has improved temperature stability relative to the widely used free fatty acid phase (FFAP) stationary phase was displayed at Pittcon 2013. Figure 1 depicts the separation of FAMES in biodiesel. In recent years, biodiesel interest has really sparked as an alternative to petroleum-based fuels. The European standard method DIN EN 14103: 2011 is used to determine the ester content of FAMEs intended for use as pure biofuel or as a blending component for heating and diesel fuels. It also allows one to determine the linolenic acid methyl ester content to verify that the linolenic acid content is between 1% (m/m) and 15% (m/m). This method is suitable for FAMEs that contain methyl esters between C6 and C24.

Figure 1: Determination of FAMEs from biodiesel. Column: 30 m à 0.25 mm, 0.25-µm df Optima FFAPplus; carrier gas: helium; flow rate: 40 cm/s; oven temperature program: 70 °C for 1 min, then 70â240 °C at 30 °C/min; injection volume: 1 µL, split 1:15; injection temperature: 260 °C; detection: MS with electron ionization; ion source temperature: 200 °C; interface temperature: 250 °C. Peaks (methyl esters): 1 = caproic acid (C6:0), 2 = caprylic acid (C8:0), 3 = capric acid (C10:0), 4 = lauric acid (C12:0), 5 = myristic acid (C14:0), 6 = palmitic acid (C16:0), 7 = palmitoleic acid (C16:1), 8 = stearic acid (C18:0), 9 = oleic acid (C18:1 cis), 10 = linoleic acid (C18:2 cis), 11 = nonadecanoic acid (C19:0), 12 = linolenic acid (C18:3), 13 = arachidis acid (C20:0), 14 = behenic acid (C22:0), 15 = erucic acid (C22:1 cis), 16 = lignoceric acid (C24:0), 17 = nervonic acid (C24:1 cis). (Courtesy of Machery-Nagel.)

Two new PLOT columns were introduced, one by Restek and one by Agilent Technologies. PLOT columns are the GC columns of choice for the analysis of light gases and low boiling volatile compounds because of their highly retentive character. However, PLOT columns generally have the disadvantage that the stationary phase layer is not mechanically stable and can be damaged easily with stationary phase particle shedding as a result. PLOT stationary phase particles flowing to the detector result in signal spikes, which can interfere with analytical results. For multicolumn valved PLOT column applications, phase particles flowing downstream into valves, Deans switches, and column connectors can cause flow restriction and damaged valve components resulting in unplanned instrumental downtime and increased maintenance costs. A new PLOT column was introduced by Agilent that has built-in particle trapping capability at both ends of the column; one end to keep particles from reaching the detector while at the other end the particle trap keeps particles from being backflushed into switching valves.

Sample Preparation Products

As indicated in Table II, Pittcon 2013 was another productive year with 24 new sample preparation products or families of products displayed. Not counted were sample preparation accessories (Table III) or sample preparation benchtop instruments (Table IV), which will be covered later. The most popular application areas included drugs and drug metabolites in biological fluids, pesticides and toxins in food, and isolation of tiny amounts of proteins and peptides. Formats included cartridges, 96-well plates, and disks.

Table II: Sample preparation products

Table II: Sample preparation products (continued)

Many of the products were for SPE and just about every mode (reversed phase, strong and weak anion and cation exchange, affinity, adsorption and normal phase, partition, and mixed mode) was represented. A wide variety of media were introduced at Pittcon including polymer-based, graphitized carbon black, silica-based bonded phases, bare silica, alumina, titania, and diatomaceous earth.

Table III: Chromatography and sample preparation accessories

This year, sample preparation introductions were dominated by the 96-well plate format; obviously these products are destined for those interested in the application of automation. Very few chemists would have the patience to manually work with such tiny wells performing SPE, filtration, and other liquid handling operations. If one doesn't have a robotic system, there are manual handheld eight-channel pipettors that relieve some of the tedium; there are even systems that are semiautomated that have 96 individual pipettors (see Table IV). The 96-well plates were introduced for SPE, filtration, and liquid handling. After the 96-well operation takes place, samples are usually collected in a 96-well collection plate and presented to an autosampler or liquid handling robot. Samples left in the collection plate sometimes sit in the autosampler for hours before analysis. Newer solvent-resistant sealing mats have been developed so that contained liquids don't evaporate and autosampler needles don't bind to. A special gas-permeable microplate seal was introduced that would allow air or CO2 to pass through it but not moisture.

An active area for which both single tubes and 96-well plates were introduced was the filtration devices for protein "crashing" experiments. Rather than using SPE and spending time developing methods, the trend in recent years has been to precipitate (crash) proteins out of biological fluids (for example, plasma) by adding an organic solvent like acetonitrile. The proteins can be removed by centrifugation (somewhat time consuming) or can be filtered through a membrane filter and the supernatant analyzed by LC–MS-MS for the drugs and other compounds. The optimum methodology is to first place the crash solvent (such as acetonitrile) in the tube or well, then add the plasma and agitate. However, with old style 96-well plates, the acetonitrile would start to drip through the bottom frit even before the plasma was added. Newer membranes have been designed that allow the organic solvent to be placed in the crash device and flow starts only when a vacuum is applied. Unfortunately, the protein crash supernatant liquid still contains a number of compounds that could interfere with MS detection mainly by causing ion suppression. Several new products were introduced that during filtration also remove the lipids and phospholipids that are some of the main culprits for ion suppression.

Table IV: Sample preparation instrumentation

Besides the normal SPE phases, newly introduced products included affinity phases that provided an activated linking group that could immobilize antibodies for protein capture or already containing immobilized antibodies that could selectively isolate aflatoxins or mycotoxins from a food or feed extract.

Table IV: Sample preparation instrumentation (continued)

Additional products for QuEChERS were introduced at Pittcon 2013. This method is an emerging technique that is becoming increasingly popular in the area of multiresidue pesticide analysis in food and agricultural products. In QuEChERS, food and agricultural samples are first extracted with an aqueous miscible solvent (such as acetonitrile) in the presence of high amounts of salts (for example, sodium chloride and magnesium sulfate) or buffering agents (such as citrate) to induce liquid phase separation and stabilize acid and base labile pesticides, respectively. Upon shaking and centrifugation, an aliquot of the organic phase is subjected to further clean up using SPE. Unlike traditional methods using SPE tubes, dispersive SPE (d-SPE) cleanup is conducted by mixing bulk amounts of SPE sorbent and additional magnesium sulfate with the extract. After sample clean up, the mixture is centrifuged and the resulting supernatant can either be analyzed directly or can be subjected to additional minor treatment before analysis. Some new QuEChERS products were displayed that provided convenient features like easy-pour salt packets and flat-bottom centrifuge tubes. A new carbonized-silica or -alumina packing has been developed that doesn't have some of the undesirable properties of graphitized carbon black, allows elution of planar pesticides without toluene, and removes matrix or pigments from colored extracts.

LLE is still a widely used sample preparation technique. The technique is often performed in separatory funnels and requires large amounts of solvent and lots of manual labor. This year's Pittcon saw the introduction of two phase separator products that are designed to make LLE easier. The SiliaPrep (Silicycle) and the Universal Phase Separator (Biotage) products are small tube-like devices that are designed to perform LLE. The Silicycle device will perform extractions with solvents heavier than water and the Biotage device will perform extractions with solvents heavier or lighter than water. Both work on the principle of a hydrophobic frit interface between the organic solvent and the aqueous solvent. The two solvents are actually in separate chambers or channels. The Silicycle SiliaPrep product has separate devices that handle 12–150 mL volumes and the Biotage device has a capacity of 70 mL. Both depend on gravity to move the fluids through the cartridge. Figure 2 provides a simple diagram of the Universal Phase Separator device.

Figure 2: Principle of operation of the Universal Phase Separator device. See Table II for details. (Courtesy of Biotage.)

Chromatography and Sample Preparation Accessories

New hardware products and accessories designed to make the life of the chromatographer easier are always popular introductions at Pittcon. This year I have separated the columns and sample preparation accessories (Table III) and small, benchtop dedicated instruments that are designated to automate sample preparation and other chromatographic techniques (Table IV). I will cover each area individually.

General Chromatography Products

Several products that can be useful for HPLC, UHPLC, and GC (plus MS and MS-MS) were shown this year. Analytical standards and reagents are always needed in a chromatography laboratory; most users gravitate to chemical suppliers or laboratory supply houses who can furnish the products that they need. Waters saw the opportunity and this year began production of chemicals needed for supporting chromatography instruments. Because the consumables (parts and supplies) business for chromatography represents a substantial market, last year Agilent Technologies launched the initial phase of its Crosslab products for competitors' gas chromatography equipment. This year, Agilent launched the next phase by making a wide range of LC consumables such as detector lamps, fittings, vials, and autosampler syringes available for its competitors' HPLC and UHPLC instruments.

Vials are used by the millions in chromatography laboratories all over the world. The 2-mL vial has been the standard for decades, but the opening on a typical vial is quite small. J.G. Finneran, a glass company, introduced the Versa Vial, which has a 9-mm-wide opening to accommodate standard pipettes. Thomson Instruments displayed their version of a filter vial. A filter vial takes the place of a syringe filter, syringes, glass vial, and cap in a single unit. The vial has a plunger that presses on a movable membrane filter frit and forces the liquid to be filtered through the membrane leaving behind the particulates. Because the unit stays intact, it can be placed directly in an autosampler.

HPLC, UHPLC, LC–MS, and Ion Chromatography Products

The advent of UHPLC has spurred a number of ultrahigh-pressure products. This year, additional high-pressure components that were introduced include fittings, PEEK-lined column hardware, PEEK-lined capillary tubing, and in-line filters.

Buffers are always a pain to prepare. So, UCT has come up with an idea borrowed from QuEChERS salt packets and now supplies pre-weighed buffers in packets — just add water. So far, only two concentrations of phosphate and acetate buffers are being supplied.

GC Products

When performing trace analysis, analyte loss and recovery is of the utmost importance. In fact, any part of the GC flowstream that touches the sample (for example, inlets including liners, capillary columns, connecting tubings, and weldments) must be thoroughly deactivated. Part of this "new" requirement is the greatly increased level of detection sensitivity now available with today's mass spectrometers that serve as the most popular GC detectors. Since detectors now operate at the femtogram level, the tiniest amounts of analyte must get through the chromatograph to be detected. Thus, ultrainert systems will be required henceforth.

Benchtop Instruments

Table IV shows 27 new products, mostly for sample preparation. Sample preparation still represents a major bottleneck in the laboratory because it is often a manual operation. Small benchtop instruments that automate some of the manual sample preparation steps can save time, eliminate tedium, and reduce errors. In this section, I cover benchtop instruments that range from robotic designs that perform multiple sample preparation procedures on small sample volumes to a single task such as solvent evaporation or mixing.

Automated liquid handling instruments are probably the more sophisticated of the benchtop units. Typically, these instruments go well beyond moving liquid samples from one container to another. For example, the CTC Analytics PAL RTC Fully Automated Prep and Load Systems, given the right accessory modules, can perform tasks such as liquid injection, headspace sampling, solid-phase microextraction (SPME), derivatization, LLE, and beyond. It has robotic tool change capabilities to widen the liquid handling up to five different liquid injection procedures. With sophisticated software, sample workflows can be managed and it even has built-in time management tools to increase throughput and avoid wasted time while a task is being performed. Of course one must pay for such sophistication, and if all of these capabilities are not required, users can consider units such as the LH96 Automated Workstation from Omni International that will perform fewer automated tasks but is still adequate for some laboratories.

At the other end of the spectrum of benchtop instruments are those that are designed to perform only one task but do it extremely well. For example, for hard and brittle samples in large pieces (such as rocks) where more than a few grams is required to get a representative sample, disk mills and pulverizers easily accomplish tasks of obtaining finely divided solids that can be easily sampled and extracted using conventional techniques. Accomplishing this task by hand would be a long and difficult process. SPE vacuum manifolds are another convenient product that speed up the SPE multistep process by batching multiple samples at a time. Evaporators that greatly speed up the drying process after collection of large volumes of analyte effluent from SPE, pressurized fluid extractors, and microwave extraction were prevalent at Pittcon. The preparation of biological samples by cell disruption and homogenization equipment save a lot of time.

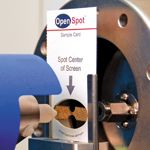

A product that was impressive to me was the DART-OS with OpenSpot sample cards. DART is an atmospheric pressure ion source that instantaneously ionizes gases, liquids, and solids in open air under ambient conditions. It was among the first ambient ionization techniques not requiring sample preparation, so solid and liquid materials can be analyzed by MS in their native state. Ionization can take place directly on the sample surface, such as currency bills, tablets, bodily fluids (blood, saliva, and urine), glass, plant leaves, fruits and vegetables, and even clothing. Liquids are analyzed by dipping an object (such as a glass rod) into the liquid sample and then presenting it to the DART ion source. The OpenSpot sample cards are a convenient way to get the sample into the source and basically don't require any elaborate sample preparation; samples are merely placed on the card by depositing a liquid or rubbing a solid material onto a wire mesh portion of the card. The card is then inserted into a holder on the source, which aligns the sample in its correct position and that's it. Figure 3 depicts a card ready to be placed into the system.

Figure 3: The DART-OS ion source with an OpenSpot sample card. (Courtesy of Ion Sense.)

Acknowledgment

I would like to thank the manufacturers and distributors that kindly furnished the requested information in advance of Pittcon 2013, thus allowing a timely report on new product introductions. For those manufacturers who would like to be considered for inclusion in the Pittcon 2014 coverage, please send the name of the primary company contact, the mailing address, phone number, and e-mail address to Laura Bush, Editor, LCGC North America, lbush@advanstar.com, with the subject line "Pittcon 2014 Column Watch."

References

(1) R.E. Majors, LCGC North Amer. 30(4), 290–310 (2012).

(2) R.E. Majors, LCGC North Amer. 30(5), 376–390 (2012).

(3) R.E. Majors, LCGC North Amer. 31(4), 280–298 (2013).

(4) The EFSA Journal 724, 1–114 (2008).

Ronald E. Majors "Column Watch" Editor Ronald E. Majors is a Senior Scientist in the Columns and Supplies Division at Agilent Technologies (Wilmington, Delaware), and is a member of LCGC's editorial advisory board. Direct correspondence about this column to lcgcedit@lcgcmag.com

Ronald E. Majors

Perspectives in Hydrophobic Interaction Temperature- Responsive Liquid Chromatography (TRLC)

TRLC can obtain separations similar to those of reversed-phase LC while using only water as the mobile phase.