Nanometer Internal Diameter Fused Silica Capillary Tubing

The Application Notebook

Scientists employ fused silica capillary tubing routinely in a wide range of analytical applications, encompassing GC, CE, capillary LC, and CEC. It has proven as an ideal substrate for interfacing in hyphenated techniques.

Synthetic fused silica capillary tubing continues to be a vital material in the separation sciences. In this application note, we present and discuss recent data on cutting edge, nanometer internal diameter capillary tubing.

Scientists employ fused silica capillary tubing routinely in a wide range of analytical applications, encompassing GC, CE, capillary LC, and CEC. It has proven as an ideal substrate for interfacing in hyphenated techniques. As the separation sciences and related analytical technologies evolve, a general trend toward smaller bore capillary tubing is clearly evident.

Polymicro Technologies™ capillary tubing leads the field in meeting this market demand by offering 25 standard products with internal diameters (i.d.) of less than 50 µm, with six of those having i.d. tolerances of ± 1 µm. The next logical innovation is the sub-1-µm regime. For many years it was felt that nanometer i.d. capillary, or "nano-capillary," could not be produced as the open bore of the capillary would close shut during the manufacturing process. After innovative developments, nano-capillary has been drawn several times in small quantities.

In this application note we discuss details of a 1 km-long experimental run of polyimide coated, fused silica-based nano-capillary.

Experimental

Nano-capillary tubing used in this study was produced on a standard Polymicro Technologies drawing tower using proprietary, optimized draw parameters. The fused silica employed was the same glass type used for similar small i.d. capillary. The objective was to produce tubing of <1 µm, but specific nanometer level targeting was not possible due to the delay between production sampling and SEM verification. Individual samples were measured using a Hitachi S4500, using a NIST traceable standard from Geller MicroAnalytical Laboratory.

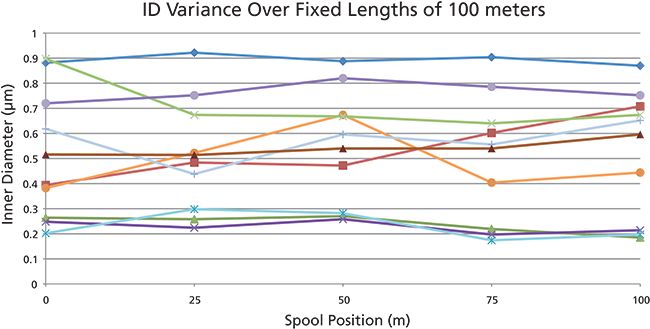

During the draw, individual batches of capillary were collected in pre-determined lengths of 100 m. Each batch was further segmented and end measurement samples taken every 25 m. The i.d. of each sample was then determined by SEM yielding 5 data points every 100 linear meters.

Figure 1: i.d. data for 100 m long batches from a 1 km draw of nano-capillary.

Results

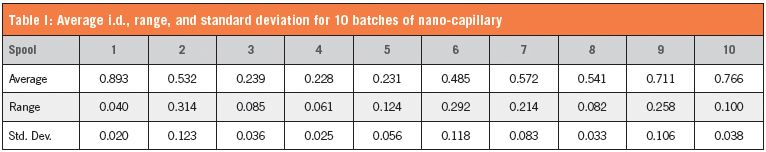

A chart of i.d. data collected from the 10 batches produced is shown in Figure 1. The i.d. target of <1 µm was met on all data points. The i.d. range within each 100 m long batch varied from a low of 40 nm to a high of 314 nm, with six of the batches having ranges of <125 nm. Table I shows a summary of the average i.d. by spool and the corresponding standard deviation. The i.d. initially trended downward from ~900 nm to nominally 200 nm and then slowly trended upward into the 800 nm range. A review of all collected data suggests that a higher frequency of measurement linearly is needed (i.e. every 10 m), which may allow for tolerances approaching ± 100 nm.

Table I: Average i.d., range, and standard deviation for 10 batches of nano-capillary

Conclusion

It is evident that through state of the art process control and metrology, providing nano-capillary tubing is possible. Finished spool length and tolerances need to be defined. The data presented in this note represents one of several studies currently under way.

Molex and Polymicro Technologies™ are trademarks or registered trademarks of Molex, LLC.

Molex

18019 N. 25th Ave., Phoenix, AZ 85023

tel. (602) 375-4100

Website: www.molex.com/capillarytubing

Automated Sample Preparation (ISO 20122) for MOSH/MOAH in Seasoning Oils

May 6th 2025This work presents an Automated Sample Preparation procedure for MOSH/MOAH analysis of Seasoning Oils. We compare results from a manual epoxidation procedure compliant with DIN 16995 with results based on fully automated sample preparation (epoxidation and saponification) compliant with ISO 20122. In both cases, online clean-up via activated aluminum oxide (AlOx) are used to remove interfering n-alkanes from the MOSH fraction during the HPLC run. Automated data evaluation using a dedicated software (GERSTEL ChroMOH) is presented.

Free Poster: NDSRI Risk Assessment and Trace-Level Analysis of N-Nitrosamines

April 25th 2025With increasing concern over genotoxic nitrosamine contaminants, regulatory bodies like the FDA and EMA have introduced strict guidelines following several high-profile drug recalls. This poster showcases a case study where LGC and Waters developed a UPLC/MS/MS method for quantifying trace levels of N-nitroso-sertraline in sertraline using Waters mass spectrometry and LGC reference standards.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)