Investigating Microalgae Using GC and HPLC–MS

Researchers from the Technical University of Denmark (DTC) have used gas chromatography (GC) and high performance liquid chromatography–mass spectrometry (HPLC–MS) to investigate microalgae biomass as an alternative resource for fishmeal and fish oil in the production of fish feed.

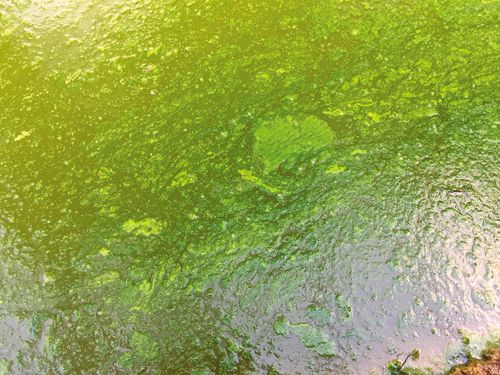

Photo Credit: Trieu Tuan/Shutterstock.com

Researchers from the Technical University of Denmark (DTC) have used gas chromatography (GC) and high performance liquid chromatography–mass spectrometry (HPLC–MS) to investigate microalgae biomass as an alternative resource for fishmeal and fish oil in the production of fish feed (1).

Alternative and sustainable aquatic feed ingredients are in short supply; this is despite intense efforts in recent years to find new sources. Currently, industrial fish not fit for human consumption and fish waste are used to create fishmeal, but this process is rapidly becoming unsustainable both environmentally and economically. An expanding world population-compounded by uncertainty in future fishing capacities-has led to a predicted shortage in fishmeal, which is used as a protein supplement in animal feed but can also be used as fertilizer.

Microalgae have emerged as a potential alternative for use in aqua culture, however, the commercial production of microalgae through photosynthesis is costly. Furthermore, the nutritional content of microalgae varies considerably between species, with environmental conditions and growth medium composition also having an effect. The study evaluated different microalgae species based on their capacity to grow on industrial process water and their ability to produce a biomass containing high levels of protein, long-chain polyunsaturated fatty acids (LC PUFA), and bioactive compounds. The two species selected were Nannochloropsis salina and Chlorella pyrenoidosa. Researchers then used this data to upscale the process from laboratory-scale experiments to large-scale flat panel photobioreactor systems. Chromatographic methods were employed for characterizing algal biomass at both pre- and post-harvest stages. A GC method was used for the analysis of fatty acids and HPLC–MS was used for the analysis of pigments. Both methods represented rapid, routine, and reliable control measures to verify the variations in the microalgae biomass during cultivation, and its quality during processing and storage.

A new downstream process was developed including a crossflow microfiltration stage by silicon carbide (SiC) ceramic membranes, heat treatment for inactivation of enzymes, up concentrations by bowl centrifuge, and drying via a swirl flash dryer. This process reduced energy consumption and reduced the deterioration of valuable bioactive compounds such as LC PUFA, natural antioxidants, and carotenoids.

These positive findings point towards microalgae as a solution to future fishmeal requirements in industry. - L.B.Reference

- H. Safafar, National Food Institute, Technical University of Denmark (2017) http://orbit.dtu.dk/en/publications/micro-algae-biomass-as-an-alternative-resource-for-fishmeal-and-fish-oil-in-the-production-of-fish-feed(9be0ea8c-70bb-4a29-b9ff-4503343f64d6).html

Accelerating Monoclonal Antibody Quality Control: The Role of LC–MS in Upstream Bioprocessing

This study highlights the promising potential of LC–MS as a powerful tool for mAb quality control within the context of upstream processing.

Using GC-MS to Measure Improvement Efforts to TNT-Contaminated Soil

April 29th 2025Researchers developing a plant microbial consortium that can repair in-situ high concentration TNT (1434 mg/kg) contaminated soil, as well as overcome the limitations of previous studies that only focused on simulated pollution, used untargeted metabolone gas chromatography-mass spectrometry (GC-MS) to measure their success.

Prioritizing Non-Target Screening in LC–HRMS Environmental Sample Analysis

April 28th 2025When analyzing samples using liquid chromatography–high-resolution mass spectrometry, there are various ways the processes can be improved. Researchers created new methods for prioritizing these strategies.

Potential Obstacles in Chromatographic Analyses Distinguishing Marijuana from Hemp

April 28th 2025LCGC International's April series for National Cannabis Awareness Month concludes with a discussion with Walter B. Wilson from the National Institute of Standard and Technology’s (NIST’s) Chemical Sciences Division regarding recent research his team conducted investigating chromatographic interferences that can potentially inflate the levels of Δ9-THC in Cannabis sativa plant samples, and possible solutions to avoid this problem.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)