Detection of Low-Level Sulfur Compounds in Spearmint Oil Using the Pulsed Flame Photometric Detector (PFPD)

Two species of spearmint oil (mentha spicata and mentha gracilis) are cultivated in the United States.

Two species of spearmint oil (mentha spicata and mentha gracilis) are cultivated in the United States. In 2008, 1.09 million kilograms of spearmint oil were produced in the US (1). Approximatley, 45% of mint oil produced in the US is used to flavor chewing gum. One 55-gallon drum of mint oil can flavor 5,200,000 sticks of gum or 400,000 tubes of toothpaste (2).

Spearmint oil is stored in glands on the underside of leaves. Mature mint plants are cut and left to dry before being chopped and transferred to a distillery. Pressurized steam vaporizes the mint oil, which passes through a condenser to be collected as a liquid. A separator takes mint oil from the liquid and transfers it into drums that are placed in a temperature-controlled warehouse. Essential oil companies test samples at this point to decide whether to purchase the oil. Gas chromatography is commonly used to assess oil quality. Oils containing impurities may undergo rectification, a re-distillation step used to purify the oil.

Volatile sulfur compounds impart undesirable odors to essential oils and have extremely low olfactory thresholds. Essential oil companies require a rapid screening technique to detect and quantify volatile sulfur compounds.

Experimental Conditions

Instrumentation used in this study was an Agilent 7890A GC equipped with an OI Analytical 5380 Pulsed Flame Photometric Detector. Two different samples of neat spearmint oil were tested. The identity of sulfur compounds in the sample was unknown, only suspected.

Results

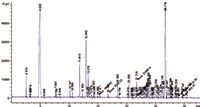

The PFPD provides two independent channels of data. One channel provides a carbon chromatogram and the second channel a sulfur chromatogram. The PFPD carbon channel chromatograms contained 65 peaks which were compared to the client's current FID chromatograms. The percent area report obtained for carbon from the PFPD closely matched the expected carbon percentages from the FID detector for hydrocarbon peaks.

Figure 1: PFPD carbon channel chromatogram of spearmint oil showing 65 peaks labeled with retention times.

The PFPD sulfur chromatograms contained nine peaks. Five peaks were confirmed as sulfur peaks in the spearmint oil using the integration time gate function of the PFPD and WinPulse software. The percent total sulfur of the smallest peak that was detected and confirmed was .00206%.

Figure 2: PFPD sulfur channel chromatogram of spearmint oil showing nine peaks labeled with retention times.

Conclusions

The study demonstrated that low-level sulfur compounds can be detected and isolated in spearmint oil using an OI Analytical 5380 PFPD detector, dual integration time gates, and comparative carbon peak matching with FID chromatograms.

References

(1) V.D. Zheljakov, C.L. Cantrell, T. Astatkie, and M.W. Ebelhar, "Productivity, Oil Content, and Composition of Two Spearmint Species in Mississippi," Agronomy Journal, Vol. 102, Issue 1 (2010).

(2) Mint Industry Research Council, www.usmintindustry.org.

OI Analytical

P.O. Box 9010, College Station, TX 77842

tel. (800) 653-1711 or (979) 690-1711, fax (979) 690-0440

Website: www.oico.com