Cleaning Protein Residues from Silica-Based Reversed-Phase Columns

What is the best way to clean protein residues from a bonded-silica reversed-phase column?

The answer to the following question was provided by LCGC’s “Column Watch” editor Ron Majors.

Q: What is the best way to clean protein residues from a bonded-silica reversed-phase column?

A: If biological materials such as plasma or serum build up on a reversed-phase column, chromatographers must use a somewhat different cleaning process. In most instances, neat organic solvents such as acetonitrile or methanol do not dissolve peptides and proteins and are ineffective for cleaning reversed-phase columns. However, mixtures of organic solvents with buffer, acids and, sometimes, ion-pairing reagents can be effective. Initially, flushing a column with mobile phase that has a somewhat higher percentage of the stronger solvent (solvent B) should be attempted.

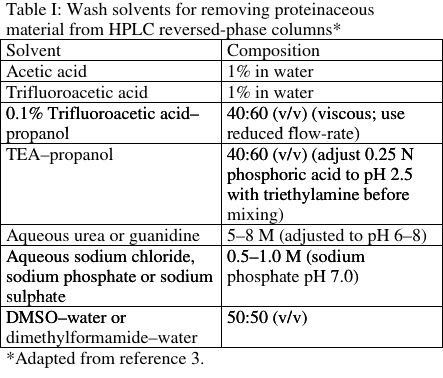

Freiser and coworkers (1) found that repeated up-and-down gradients between aqueous trifluoroacetic acid and trifluoroacetic acid–propanol can regenerate contaminated reversed-phase columns. Bhadwaj and Day (2) suggested that a plug injection of 100 μL of trifluoroethanol in a 250 mm X 4.6 mm column could work. If these procedures fail, the strong eluents or solubilizing agents recommended by Cunico and colleagues (3) can be used to strip proteins (see Table I). Before flushing columns with these solvents, however, consult the column manual or the manufacturer to ensure that these solvents are compatible with the packing material. Silica-based columns are usually compatible but organic polymer–based columns can swell or shrink with certain solvent combinations, and the performance could be affected.

As with the previous solvent series, ensure that the sets of solvents in Table I used in series are miscible. Propanol is a good intermediate flush solvent. A minimum of 20 column volumes should be used for each solvent system. Because some of the solvent systems are quite viscous, the flushing flow-rates should be adjusted accordingly to ensure that no overpressuring occurs. After cleaning a column with the guanidine or urea reagents, use a minimum of 40–50 column volumes of HPLC-grade water to flush the column.

For reversed-phase columns, it has been inadvisable to use detergents such as sodium dodecyl sulfate (SDS) and Triton, because these compounds are apparently adsorbed strongly on bonded-silica packing and are difficult to remove. Using detergents can affect the surface of the packing and change its characteristics. However, a study by the Separations Group found that a column contaminated by a protecting group and scavenger products from a peptide synthesis could be cleaned by injecting 500 μL of 1% SDS solution into the mobile phase flowing at 1 mL/min (4). If followed by a gradient from 5% to 95% acetonitrile with 0.1% (v/v) trifluoroacetic acid and equilibration at the starting conditions, the polypeptide separation was restored.

(1) H.H. Freiser et al., “The Use of Stabilized Silica Support with a Short Alkyl Chain for Reversed-Phase Preparative Chromatography of Proteins,” product bulletin number 10, Micra Scientific (Northbrook, Illinois, 1988).

(2) S. Bhardwaj and R.A. Day, LCGC 17(4), 354–356 (1997).

(3) R.L. Cunico, K.M. Gooding and T. Wehr “Basic HPLC and CE of Biomolecules,” Bay Bioanalytical Laboratory (Richmond, California, 1998), p. 254.

(4) “Reversed-Phase Column Cleaning: SDS is OK,” Vydac Advances, Grace/Vydac (The Separations Group) (Hesperia, California, Winter 1998).

If you have a question you'd like answered, please submit them at Ask LCGC. We look forward to hearing from you!

Regulatory Deadlines and Supply Chain Challenges Take Center Stage in Nitrosamine Discussion

April 10th 2025During an LCGC International peer exchange, Aloka Srinivasan, Mayank Bhanti, and Amber Burch discussed the regulatory deadlines and supply chain challenges that come with nitrosamine analysis.