Analyzing the Safety Aspects of Onsite Hydrogen Generation Versus High Pressure Cylinders for Use in GC Applications

Proton OnSite

Permitting and safely managing inventories of flammable hydrogen is a common concern in a laboratory. Laboratories can choose to install an on-site hydrogen gas generator or have bottled hydrogen gas delivered to the workspace and stored in classified areas.

GC practitioners who use hydrogen need to take precautions to ensure the safety of their laboratory, as an unintended leak due to downstream equipment failure can quickly create an explosive atmosphere; several incidents have been reported (1). Hydrogen in air can ignite when exposed to the energy in a static discharge, as low as 0.017 mJ; the Lower Flammability Limit (LFL) is 4% H2 in air, by volume (2). Frequently replacing depleted high-pressure hydrogen cylinders creates a chance for accidents.

More than one standard H2 cylinder exceeds code minimum limits, imposing special building construction, separation distances, and increased facility costs — especially when co-located with other research gases (3,4). One standard H2 cylinder, storing 6300 liters of H2 gas, has the explosive potential of 35 lb of TNT.

Comparative Analysis:

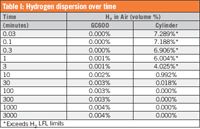

The Proton OnSite® HOGEN® GC600 hydrogen gas generator can serve up to five typical GC instruments continuously with FID fuel and carrier gas. Internally, it contains less than 3 liters of H2 at any time. Table I shows that the GC600, with a maximum H2 flow rate of 600 cc/min, was allowed to flow unchecked into a 3000 ft3 laboratory space with 12 air changes per hour (5).

Table I: Hydrogen dispersion over time

In comparison, a standard DOT 3AA-2400 H2 gas cylinder can serve the same 5 GC instruments for up to 65 h before it must be replaced. Table I also shows the 6300 liter contents of a single H2 cylinder were to be released unchecked in the same 3000 ft3 laboratory space.

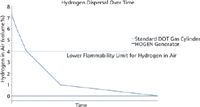

Figure 1: Hydrogen release dispersed in a 3000 ft3 laboratory space outlined in Table I. The Standard DOT Gas Cylinder’s release very quickly exceeds LFL. The Proton OnSite HOGEN GC600 release of hydrogen fails to come near to dangerous levels even after an extended period of time.

Conclusions

GC practitioners must manage hydrogen supplies with the utmost care to avoid leaks and releases, which can quickly create an explosive atmosphere in a laboratory. But, even without proper due diligence, the checks and balances within Proton's listed HOGEN hydrogen generators mean a release will not meet hydrogen's LFL levels, as opposed to a standard H2 cylinder which, if left unchecked, could create a dangerous atmosphere in less than 3 min.

References

(1) PNNL, H2 Incident Reporting, laboratories, http://www.h2incidents.org/sort.asp?cat=2&val=1.

(2) Basic considerations for the safety of hydrogen systems, ISO/TR 15916:2004.

(3) NFPA 55, Compressed Gases and Cryogenic Fluids Code.

(4) NFPA 2, Hydrogen Technologies Code.

(5) ASHRAE 62.1-2010 minimum 12 ACH rate for science labs based on 0.18 cfm/ft2 floor area, with a 9 ft ceiling.

Proton OnSite

10 Technology Drive, Wallingford, CT 06492

tel: (203) 949-8697; fax: (203) 949-8016

Website: www.protononsite.com

The Benefits of Custom Bonded Silica

April 1st 2025Not all chromatography resins are created equal. Off-the-shelf chromatography resins might not always meet the rigorous purification requirements of biopharmaceutical manufacturing. Custom bonded silica from Grace can address a wide range of separation challenges, leading to real performance improvements. Discover more about the latest innovations in chromatography silica from Grace, including VYDAC® and DAVISIL®.

5 Things to Consider When Selecting a Chromatography Silica

April 1st 2025Particularly in the pharmaceutical industry, drug purity isn’t just a goal – it’s essential for achieving safety, stability and efficacy. However, purification is easier said than done, especially with challenging molecules like DNA and RNA “oligonucleotides,” due in large part to their diversity and the range of impurities that can be generated during production. Enter DAVISIL® chromatographic silica, with a wide range of pore diameters and particle sizes to meet your specific application, performance and sustainability requirements. Before you choose the chromatography resin for your next purification application, take a look at these 5 considerations.

Automating Protein Purification: Efficiency, Yield, and Reproducibility

March 27th 2025Recent advancements in automated protein purification stress the importance of efficiency, scalability, and yield consistency. This eBook compares different purification platforms, highlighting their impact on downstream applications and demonstrating how automation enhances throughput and process control.

MilliporeSigma: Ultrapure Water for Sensitive LC-MS Analysis of Pesticides

March 25th 2025The aim of the study was to illustrate the efficiency of Milli-Q® water purification systems in eliminating pesticides from tap water, thereby producing and delivering reliable and consistent-quality ultrapure water suitable for pesticides analysis