Advancing Food Analysis with Ultrahigh-Pressure Liquid Chromatography and High-Resolution Mass Spectrometry

Specialists in food analysis are increasingly interested in taking advantage of methods that harness the power of ultrahigh-pressure liquid chromatography (UHPLC) and high-resolution mass spectrometry (HRMS). Jon Wong of the Center for Food Safety and Applied Nutrition at the U.S. Food and Drug Administration has been developing such methods for a variety of types of analysis. In this interview, he talks to LCGC about the work to develop these methods and the advantages of their use.

Specialists in food analysis are increasingly interested in taking advantage of methods that harness the power of ultrahigh-pressure liquid chromatography (UHPLC) and high-resolution mass spectrometry (HRMS). Jon Wong of the Center for Food Safety and Applied Nutrition at the U.S. Food and Drug Administration has been developing such methods for a variety of types of analysis. In this interview, he talks to LCGC about the work to develop these methods and the advantages of their use.

Q. You collaborated in developing a method for analyzing multiple mycotoxins in finished grain and nut products using ultrahighâpressure liquid chromatography and highâresolution mass spectrometry (UHPLC–HRMS) (1). Why did you undertake this work?

A: At the time, UHPLC–HRMS was a relatively new technology to us and it required evaluation to determine if there were significant benefits and advantages over the current and widely accepted UHPLC–triple-quadrupole MS technology (LC–MS/MS) being used for food safety analysis. We decided to focus on mycotoxins because we had recently developed an LC–MS/MS method for mycotoxins in grains and nuts (2), and since there were still materials remaining from that study, we used the same preparation procedures on the samples and analyzed them on a UHPLC–HRMS system for evaluation and comparison. UHPLC–HRMS was not only quantitative and just as sensitive as the LC–MS/MS method but it could also provide more information for identification. The results showed that the same product ions are formed in both LC–MS/MS and UHPLC–HRMS despite the different MS platforms, but the high-accuracy masses in HRMS provided better details to speculate about how the mycotoxin precursor could fragment and form into product ions. We began to realize and recognize the possibilities and the drawbacks of UHPLC–HRMS based on this experience.

Q. What are the advantages and disadvantages of UHPLC–HRMS over LC–MS/MS? For what types of analysis would you favour one technology over the other?

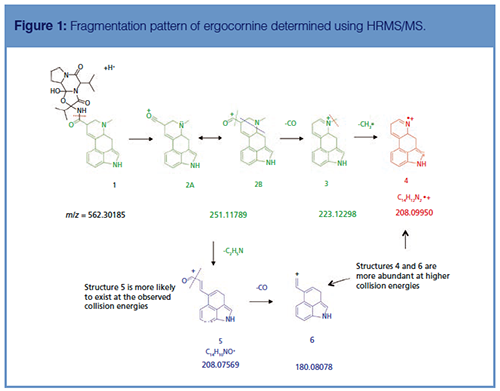

A: One obvious advantage of UHPLC–HRMS over LC–MS/MS is the better data quality and confidence in the results when you can determine the mass of the molecular ion to four or five decimal places. This precision is extremely useful for fragmentation studies and to assign proposed structures. An example that convinced us of one of the benefits of HRMS came from the mycotoxin studies. We were comparing and matching the mass-to-charge ratio (m/z) results from product ions obtained from our UHPLC –high-resolution data-dependent MS/MS experiments of ergocornine and its products with results obtained from LC–MS/MS (using a tripleâquadrupole mass analyzer), provided from a publication from another research group (3). Our UHPLC–high-resolution dataâdependent MS/MS results agreed with most of the results except for m/z 208.1. Our calculated mass of 208.07569 from our experimental results did not agree with the proposed structure 4, C14H12N2•+, assigned in the other group’s paper, which resulted in a calculated mass of 208.09950 but with a mass accuracy of δM = –113.05 using the experimental mass value obtained from our HRMS studies. This result indicated to us that the proposed structure 4, shown in Figure 1, was not possible. The experimental mass indicated that the structure had to have an elemental composition of C14H10NO+, which was possible if structure 2 were to fragment and lose –C2H5N to form structure 5. However, we saw that the other group’s paper was correct; we were able to find structure 4 at higher collision energies but we also found further evidence to support structure 5 as a loss of –CO, resulting in a calculated mass of 180.08078 to support the formation of structure 6, which was also experimentally found. These studies were extremely useful to determine the elemental composition, elucidate fragmentation patterns, and propose and assign structures of the product ions. This information can be useful and helpful by knowing the stability of these product ions and deciding the precursor-to-product ion transitions used in LC–MS/MS analysis of chemical residues and contaminants. These experiences really helped us see the benefits of HRMS analysis.

LC–HRMS is still relatively new to those in the food safety and environmental field, but people are learning more about it. The main disadvantage of HRMS is that the data files are huge and eventually one needs to have sufficient storage space to save all these data.

Little prior information is required to set up an HRMS procedure with an associated full-scan component as long as the analyte can be chromatographically separated, the analyte is efficiently and effectively ionized, and the associated masses of the analyte are detected. Although LC–MS/MS is selective and sensitive, it is a restricted and targeted procedure that requires a priori knowledge of the analyte’s retention time and precursor and product ion masses. However,

LC–MS/MS is still the standard procedure for LC–MS analysis of chemical contaminants and residues. As long as you know what your target analytes are, LC–MS/MS is the preferred approach for analysis. The current identification criteria of pesticide and veterinary drug residue, natural toxins, and processing contaminants are mature and well established for LC–MS/MS analysis but they are being developed for LC–HRMS analysis.

A drawback for LC–MS/MS procedures arises in multiresidue screening, especially when the list of pesticides is large. For example, if you are screening for 500 pesticides, the MS/MS method will require at least 1000 precursor-to-product ion transitions (because two are usually required for each pesticide) and pesticide retention times. Maintaining such a method would be difficult. We are trying to develop LC–HRMS procedures to screen large volumes of compounds using HRMS/MS libraries and compound databases that may be easier to manage.

Q. Have you been able to expand the use of HRMS to the analysis of other chemicals involved in food safety?

A: Yes. We are collaborating with scientists at the Canadian Food Inspection Agency Our collaborations have led to validated UHPLC–HRMS procedures to analyze pesticides in fruits and vegetables (4) and veterinary drugs in milk (5). Typical sample preparation procedures such as QuEChERS (quick, easy, cheap, effective, rugged, and safe) for pesticides in fruits and vegetables and modifications of a procedure using solid-phase extraction for veterinary drugs on milk worked well when these extracts were analyzed with UHPLC–HRMS. In these two projects, and in the mycotoxin project, we were able to quantitatively analyze food samples using UHPLC and data-dependent acquisition HRMS (UHPLC–DDA–HRMS) and the results were obtained just as easily as with LC–MS/MS.

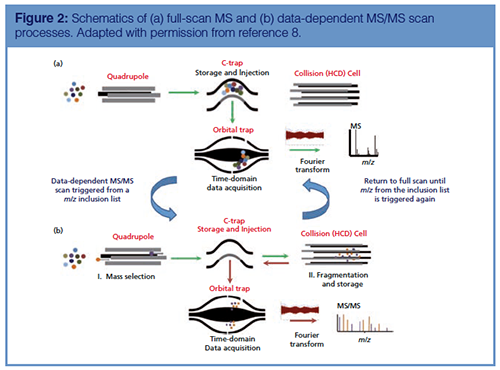

This work using full-scan MS and DDA MS/MS (schematic shown in Figure 2) was similar to work we had done earlier on a hybrid quadrupole–ion trap mass spectrometer to generate multiple reaction monitoring (MRM) spectra of product ions instead of the two MRM precursor-to-product transitions (6). The work on the hybrid MS system had some limitations and required scoring or matching factors that were difficult to implement for identification. The advantage of the HRMS DDA spectra is that identification could be determined based on retention time and mass accuracy of the precursor and product ions of the chemical of interest. This work and previous experiences in which using state-of-the-art technology has improved our work have convinced us that LC–HRMS is going to have a major role in the future of chemical residue and contaminant screening and analysis.

Q. You mentioned some of your previous collaboration with the Canadian Food Inspection Agency. More recently, you have been working with that agency to develop systematic and detailed protocols for screening for chemical residues in foods (7). Why did you start collaborating, and why did you undertake the development of this method in particular?

A: Research in developing large-scale screening methods requires a lot of resources and time, and our agencies have a mutual interest and an agreement to evaluate the UHPLC–HRMS technology and its potential applications for screening pesticides and other chemical residues and contaminants in foods. It is better to collaborate to avoid duplication of the work and to lessen the work burden since we have the same goals and interests.

We are trying to accomplish several tasks for developing effective LC–HRMS screening procedures. One is to create HRMS/MS libraries for chemical residues and contaminants such as pesticides, veterinary drugs, and mycotoxins so that we can extract the calculated masses of the product ions and deposit them into a compound database. The compound database can be implemented in the software for data processing applications such as screening, which can determine the presence of residues or contaminants that may be present in a food sample subjected to LC–HRMS analysis. The libraries and databases are tedious to build because every major product ion in the MS/MS spectra requires evaluation, but this work is necessary to build a comprehensive database. A second area we are involved in is to develop, evaluate, and validate UHPLC–HRMS/MS experiments in DDA and dataâindependent acquisition (DIA) modes for quantitative analysis and qualitative screening. This work has been done for the analysis of pesticides in fruits and vegetables and veterinary drugs in milk. Our goal is to determine which LC–HRMS procedure would be effective based on the application and need. Finally, by collaborating with another agency, we can perhaps harmonize what sample preparation and instrumental methods and conditions are to be used for quantitative or screening analysis for different analyte or food classes.

Q. You used the full-scan DDA mode to acquire product ion spectra of individual pesticides to obtain the accurate masses of fragments that were used to build the compound database and MS library, but you used DIA mode to acquire the sample data. Why?

A: Under DDA mode, the precursor ions are selected by the quadrupole within a narrow m/z window-~1–4 Da wide-and are transferred to the high energy collision dissociation (HCD) cell to produce product ions. Information of the precursor ions and their retention times are required a priori to trigger a targeted MS/MS response. This approach is ideal to create an MS/MS spectrum for the chemical analyte of interest because only the product ions are detected and there is minimal interference present in the spectrum due to the narrow m/z window. It is also ideal for building MS/MS spectra libraries. The product ions generated from the DDA-MS/MS spectra originate from only the precursor ion of interest. We initially used DDA for the quantitative analysis of mycotoxins, pesticides, and veterinary drugs because we were evaluating the HRMS using full MS and DDA-MS/MS scans to determine if we could develop a targeted approach similar to an LC–MS/MS procedure.

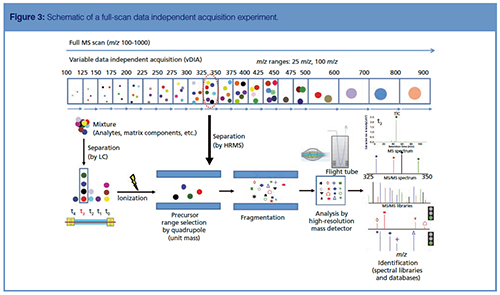

DIA utilizes the quadrupole to perform a precursor or survey scan of selected ions using mass range windows. In our work, a variable DIA (vDIA) procedure was developed using 16 mass range windows with a width of 25 m/z for

100–500 m/z and four mass range windows with a width of 100 m/z for 500–900 m/z. A full MS scan was also implemented from a range of 100–1000 m/z. The schematic of the experiment is shown in Figure 3. The ions in the vDIA experiments are subjected to fragmentation and MS/MS analysis according to the progression of the mass range window. This approach is ideal for screening applications because all of the ions in the 100–900 m/z range will eventually undergo fragmentation in the collision cell and the product ions will be analyzed in the mass analyzer.

The instrument software, along with the MS/MS libraries and compound databases, can be used to sort and identify any chemical present in the sample (as long as the chemical is logged in the library and database). MS/MS spectra from DIA scans for library applications are not ideal because multiple analytes can be coeluted chromatographically and can potentially be within the mass-range window. The resulting product ions would be difficult to discriminate from the different precursors in the same MS/MS spectrum. Given the smaller m/z window range and retention time trigger of the targeted precursor, results from DDA would be more reliable to build the library and database.

Q. What are the next steps in your work?

A: We would like to expand and apply UHPLC–HRMS to screening chemical residues and contaminants in important food commodities. It would be ideal to be able to expand and combine all the

MS/MS libraries and databases to screen for not only pesticide residues but also veterinary drugs, mycotoxins, processing contaminants, and other contaminants that can potentially be present in food and other commodities. We will continue to evaluate, optimize, and advance HRMS applications to complement LC–MS/MS methods or to combine screening with quantitative analysis.

References

- C.-D. Liao, J.W. Wong, K. Zhang, P. Yang, J.B. Wittenberg, M.W. Trucksess, D.G. Hayward, N.S. Lee, and J.S. Chang, J. Agric. Food Chem.63, 8314−8332 (2015).

- C.-D. Liao, J.W. Wong, K. Zhang, D.G. Hayward, and M.W. Trucksess, J. Agric. Food Chem. 61, 4771–4782 (2013).

- R. Mohamed, E. Gremaud, J.-C. Tabet, and P.A. Guy, Rapid Commun. Mass Spectrom. 20, 2787–2799 (2006). DOI: 10.1002/rcm.2648.

- J. Wang, W. Chow, J. Chang, and J.W. Wong, J. Agric. Food Chem.62, 10375–10391 (2014).

- J. Wang, W. Chow, J. Chang, and J.W. Wong, J. Agric. Food Chem.63, 9175–9187 (2015).

- K. Zhang, J.W. Wong, P. Yang, D.G. Hayward, T. Sakuma, Y. Zou, A. Schreiber, C. Borton, T.V. Nguyen, K. Banerjee, and D. Oulkar, Anal. Chem.84, 5677–5684 (2012).

- J. Wang, W. Chow, J. Chang, and J.W. Wong, J. Agric. Food Chem.65, 473–493 (2017).

- A. Michalski, E. Damoc, J.P. Hauschild, O. Lange, A. Wieghaus, A. Makarov, N. Nagaraj, J. Cox, M. Mann, and S. Horning, Mol. Cell Proteomics10(9), M111.011015 (2011). DOI: 10.1074/mcp.M111.011015.

Jon W. Wong, PhD, is a research chemist at the Center for Food Safety and Applied Nutrition at the U.S. Food and Drug Administration, in College Park, Maryland, USA. Direct correspondence about this article to: Jon.Wong@fda.hhs.gov.

New TRC Facility Accelerates Innovation and Delivery

April 25th 2025We’ve expanded our capabilities with a state-of-the-art, 200,000 sq ft TRC facility in Toronto, completed in 2024 and staffed by over 100 PhD- and MSc-level scientists. This investment enables the development of more innovative compounds, a broader catalogue and custom offering, and streamlined operations for faster delivery. • Our extensive range of over 100,000 high-quality research chemicals—including APIs, metabolites, and impurities in both native and stable isotope-labelled forms—provides essential tools for uncovering molecular disease mechanisms and exploring new opportunities for therapeutic intervention.

New Guide: Characterising Impurity Standards – What Defines “Good Enough?”

April 25th 2025Impurity reference standards (IRSs) are essential for accurately identifying and quantifying impurities in pharmaceutical development and manufacturing. Yet, with limited regulatory guidance on how much characterisation is truly required for different applications, selecting the right standard can be challenging. To help, LGC has developed a new interactive multimedia guide, packed with expert insights to support your decision-making and give you greater confidence when choosing the right IRS for your specific needs.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)