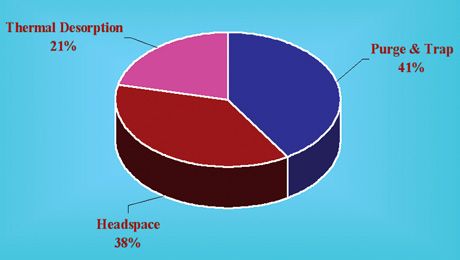

Volatile Extraction Market

The volatile extraction market consists of three techniques: purge and trap, headspace, and thermal desorption equipment.

The volatile extraction market consists of three techniques: purge and trap, headspace, and thermal desorption equipment. These systems are often employed as a sampling method for gas chromatography (GC) instrumentation but are also used with IR detectors, electrochemical sensors of electronic noses, and mass spectrometers.

Separation Instrumentation Demand

The volatile extraction market is primarily a systems market with purge and trap accounting for the largest market share. Purge and trap involves the bubbling of an inert gas, such as nitrogen or helium, through an aqueous sample, which liberates the volatile organic compounds (VOCs) that are either dissolved in the sample or present in a solid sample that is then suspended in the aqueous sample. Purge and trap technology enables GC and GCâMS systems to achieve lower levels of detection. Headspace, however, is the most common volatile extraction technique in terms of units sold. Industries with the highest demand for headspace extraction are chemical, forensics, food and beverage, pharmaceutical, and environmental testing.

Thermal desorption systems are efficient and highly sensitive. But, shortcomings of the technology have limited its market share. Still, thermal desorbers are widely used for environmental testing, often in the monitoring of air quality, chemical exposures in workplaces, and identifying fragrances and other ingredients. Thermal desoprtion systems are especially common in countries where environmental monitoring is of greater concern such as China and part of Latin America. Most GC vendors manufacture volatile extraction equipment or they have OEM arrangements with volatile extraction vendors in order to offer complete analytical solutions to their customers.

The foregoing data was extracted from SDi's “Market Brief on Volatile Extraction.” For more information, contact Glenn Cudiamat, VP of Research Services, Strategic Directions International, Inc., 6242 Westchester Parkway, Suite 100, Los Angeles, CA 90045, tel. (310) 641-4982, fax (310) 641-8851, e-mail cudiamat@strategic-directions.com.

New TRC Facility Accelerates Innovation and Delivery

April 25th 2025We’ve expanded our capabilities with a state-of-the-art, 200,000 sq ft TRC facility in Toronto, completed in 2024 and staffed by over 100 PhD- and MSc-level scientists. This investment enables the development of more innovative compounds, a broader catalogue and custom offering, and streamlined operations for faster delivery. • Our extensive range of over 100,000 high-quality research chemicals—including APIs, metabolites, and impurities in both native and stable isotope-labelled forms—provides essential tools for uncovering molecular disease mechanisms and exploring new opportunities for therapeutic intervention.

New Guide: Characterising Impurity Standards – What Defines “Good Enough?”

April 25th 2025Impurity reference standards (IRSs) are essential for accurately identifying and quantifying impurities in pharmaceutical development and manufacturing. Yet, with limited regulatory guidance on how much characterisation is truly required for different applications, selecting the right standard can be challenging. To help, LGC has developed a new interactive multimedia guide, packed with expert insights to support your decision-making and give you greater confidence when choosing the right IRS for your specific needs.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)