Tips & Tricks GPC/SEC: Strategies to Save Solvent

The Column

Tetrahydrofuran (THF) - a widely used solvent in gel permeation chromatography/size-exclusion chromatography (GPC/SEC) - is set to be classified as carcinogenic as proposed by the Committee for Risk Assessment (RAC). Analytical laboratories therefore need to find ways to reduce THF solvent use and waste, far beyond the demands of green chemistry. This instalment of Tips & Tricks presents different strategies to meet this goal.

Tetrahydrofuran (THF) - a widely used solvent in gel permeation chromatography/size-exclusion chromatography (GPC/SEC) - is set to be classified as carcinogenic as proposed by the Committee for Risk Assessment (RAC). Analytical laboratories therefore need to find ways to reduce THF solvent use and waste, far beyond the demands of green chemistry. This instalment of Tips & Tricks presents different strategies to meet this goal.

Photo Credit: Getty Images/Tuomas Kujansuu

Resolution in gel permeation chromatography/size-exclusion chromatography (GPC/SEC) depends on two parameters - the available pore volume and the dispersion in the system as indicated by the plate count. It is common practice in GPC/SEC to combine several columns in a column bank to increase resolution and molar mass separation range; however, this increases analysis time, solvent consumption, and waste. Here, we present a number of ways to perform environmentally friendly GPC/SEC.

Overlaid Injection

Overlaid injection introduces a sample onto the column while the previous sample is still eluting from the column. The maximum amount that the samples can be overlaid is equivalent to the interstitial volume of the column. Using overlaid injection can reduce solvent consumption by 25–35% and is an elegant way to save time. The big advantage of this is that it does not sacrifice resolution and can be performed with columns from all manufacturers.

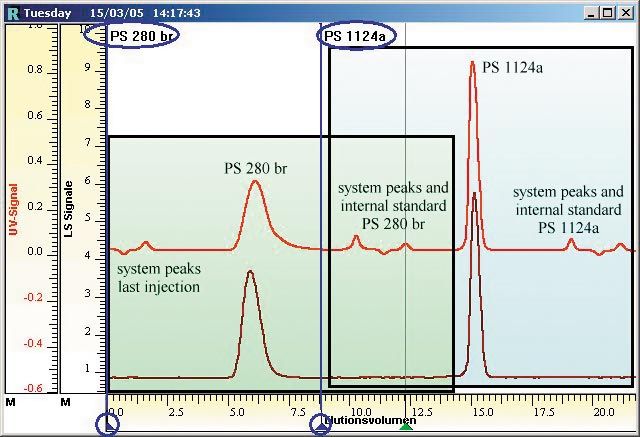

Figure 1 shows an example of an overlaid injection with UV and light scattering data for two samples. The first sample elutes with the internal flow marker around 12.5 mL (min); however, the next sample PS 1124a is already injected after approximately 8.25 mL (min). If software is used correctly, overlaid injection does not affect the data evaluation of results.

Figure 1: Overlaid injection example. Before the system peaks and the internal standard (light green triangle) of “PS 280 br” are eluted, the next sample “PS 1124 a” is already injected at 8.5 mL (blue triangle). The analysis and data evaluation of sample “PS 280 br” is not affected by that; baseline and integration limits can be set as required by national and international GPC/SEC guidelines, for example, ISO 13885/DIN 55672.

Column Concepts

Reducing particle size can increase resolution in GPC/SEC as in ultrahighâpressure liquid chromatography (UHPLC), saving time and solvent, but it is still a concept under investigation. In the case of macromolecules, for example, forcing high molar mass or stiff polymer chains through an LC system at very high pressure can result in chain degradation and will generate results only for the fragments.1 Despite this, many applications for oligomers or spherical and stable macromolecules can be transferred to newer solutions. Depending on the GPC/SEC equipment two approaches can be applied:

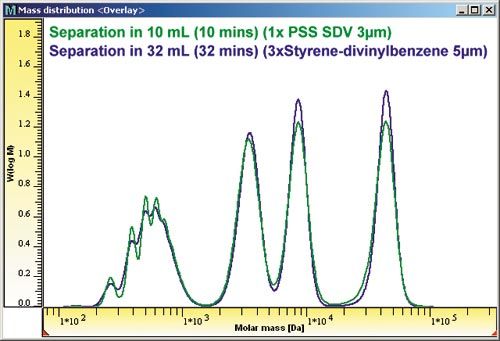

a) Continue to use traditional analytical columns with an internal diameter of approximately 8 mm and filled with particles of the same chemistry and pore size, but a different particle size. Figure 2 compares the resolution of a polystyrene oligomer on styrene-divinylbenzene material with different particle sizes. Using 3-µm particles allows separations with the same or better resolution on just one or two analytical columns instead of three. This decreases the amount of solvent and waste significantly.

Figure 2: Resulting molar mass distribution for a polystyrene mixture of four different molar mass calibrants including an oligomer mixture. For one styrene-divinylbenzene column (8 × 300 mm, 3-µm) a better resolution can be achieved in less time and using less solvent than when using a combination of three 5-µm styrene-divinylbenzene columns with a comparable pore size distribution.

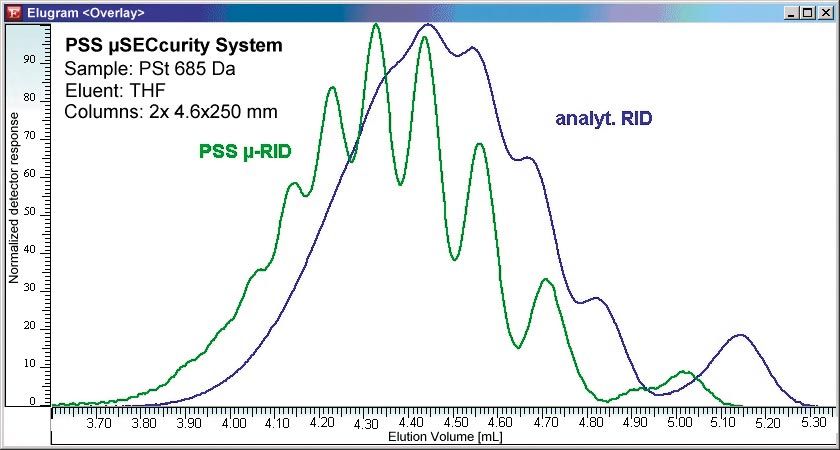

b) Even more solvent can be saved when the internal diameter of the columns is reduced from 8 mm to around 4.6 mm; however, the cell volume of a lot of traditional GPC/SEC detector cells is too large to profit from the enhanced separation using semi-microcolumns. While UV–vis detectors are, in general, ready for these applications, either upgrade of existing refractive index detectors (RI) or purchase of new, optimized µRIs, light scatterings detectors, or viscometers is required. Figure 3 shows how the excellent resolution of microcolumns gets lost when analytical RI detectors are used for detection. Optimized µRIs provide much better results.

Figure 3: Comparison of the chromatogram of a polystyrene oligomer separated in 5.5 mL using micro columns and a standard RI detector (blue trace) versus an optimized µRI detector with smaller cell volume (green trace).

Intelligent Calibration

Another way that solvent can be saved is by using an intelligent approach to calibration. GPC/SEC calibration involves measuring the elution volume of several molar mass calibration standards. It is normally possible to inject a combination of three to four standards in the same injection if the standards differ significantly in molar mass. If the separation is sufficient, even more standards can be added and analyzed within the same run. A 10- to 12-point calibration curve can therefore be created with three injections or less, but care is required in choosing the correct concentration for the different molar masses.2 Mixtures of high quality reference materials with precise concentrations and molar masses are available as polymer cocktails pre-weighed into autosampler vials, eliminating the need to weigh in calibrants.

Detector Concepts

Multi-detection is one of the strengths of GPC/SEC - molar mass sensitive detectors, such as on-line viscometers (stand-alone or as part of a triple detection system), provide valuable information for many applications. All commercially available detectors apply the same major principle: they split the sample eluting from the column in a bridge design and compare the viscosity (or, more precisely, the pressure in the tubing) of the pure mobile phase with that of the sample.

The viscosity of the pure solvent is measured using either hold-up columns or a reservoir filled with solvent. If a detector has a reservoir, the split part of the sample is diluted to zero concentration in that reservoir. If a detector uses holdâup columns, the split part of the sample is delayed while travelling through these hold-up columns. The delayed sample parts then elute after the system peaks of the sample. They are visible as negative peaks in the delta pressure signals of the viscosity detector. Therefore, the amount of solvent required per sample is much higher for viscometers with holdâup columns than for viscometers with reservoirs.

Summary

There are several ways to save solvent and to avoid waste in GPC/SEC.

Overlaid injection reduces solvent consumption by 25–35%, without sacrificing the resolution; however, dedicated software is required.

- Reducing particle size to reduce the number of columns required for a good resolution is applicable for many applications of compact and low molar mass macromolecules. For example, applications in THF or other organic solvents can be transferred from 5 µm styrene-divinylbenzene to 3 µm. Aqueous separations can be run on 5 µm for typical water-soluble polymers or biopolymers, or 2–3 µm for proteins.

- The use of microcolumns with a reduced internal diameter requires an adjustment of the cell dimensions of typical GPC/SEC detectors. For some RI detectors a detector modification is available.

- For on-line viscometry/triple detection the use of viscometers with a

- reservoir instead of hold-up columns halves the amount of solvent required because there is no need to wait for a negative peak.

References

- A. Striegel, W.W.Yau, J.J.Kirkland, and D.D. Bly, Modern Size-Exclusion Liquid Chromatography: Practice of Gel Permeation and Gel Filtration Chromatography (John Wiley & Sons, New York, USA, 2009).

- D. Held, The Column9(6), 9–12 (2013).

Daniela Held studied polymer chemistry in Mainz, Germany, and works in the PSS software and instrument department. She is also responsible for education and customer training.

Jasmin Preis studied polymer chemistry in Mainz, Germany, and works in the PSS production department. She is responsible for custom synthesis of specialty polymers and particles.

E-mail: Dheld@pss-polymer.com

Website: www.pss-polymer.com

New Method Explored for the Detection of CECs in Crops Irrigated with Contaminated Water

April 30th 2025This new study presents a validated QuEChERS–LC-MS/MS method for detecting eight persistent, mobile, and toxic substances in escarole, tomatoes, and tomato leaves irrigated with contaminated water.

Accelerating Monoclonal Antibody Quality Control: The Role of LC–MS in Upstream Bioprocessing

This study highlights the promising potential of LC–MS as a powerful tool for mAb quality control within the context of upstream processing.

University of Tasmania Researchers Explore Haloacetic Acid Determiniation in Water with capLC–MS

April 29th 2025Haloacetic acid detection has become important when analyzing drinking and swimming pool water. University of Tasmania researchers have begun applying capillary liquid chromatography as a means of detecting these substances.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)