Tips & Tricks GPC/SEC: How to Determine dn/dc Values

This instalment of Tips & Tricks discusses the different approaches for determining the refractive index increment (dn/dc).

The refractive index increment (dn/dc) is an essential parameter when analyzing light-scattering (LS) data, independent of the LS method applied. This instalment of Tips & Tricks discusses the different approaches for determining this crucial value.

Light scattering is an absolute method for measuring molar mass and is therefore an important tool when analyzing polymers, biopolymers, and proteins. Many R&D and QC labs combine light-scattering detectors with separation techniques such as gel permeation chromatography/size-exclusion chromatography (GPC/SEC). However "absolute" does not mean parameter-free, rather the opposite. One of the most important parameters for light scattering is the refractive index increment (dn/dc), because this sample and method related parameter determines if light-scattering can be successfully applied and calculates accurate results.

Photo Credit: ROBERT BROOK/Getty Images

What is the dn/dc?

The refractive index increment (dn/dc) refers to the rate of change of the refractive index with the concentration of a solution for a sample at a given temperature, a given wavelength, and a given solvent:

Above a certain molar mass, the influence of end groups can be neglected and the dn/dc of homogeneous polymers is constant and can be considered as a contrast factor. A high dn/dc indicates higher signal intensity and therefore higher accuracy and precision. This can be easily understood by looking at equation 2, which shows the dependency of the signal intensity for LC detectors from the most important instrumental and experimental parameters:

In addition to the detector constant (KDet) and the concentration (or injected molar mass), signal intensity also depends on a sample related constant (ksample) and may depend on the molar mass (M). The molar mass exponent × equals 1 for a molar mass sensitive detector (such as an light scattering detector) and is 0 for a typical concentration detector (such as an refractive index detector [RI]). When using either an RI or a light-scattering detector, ksample is equal to the dn/dc.

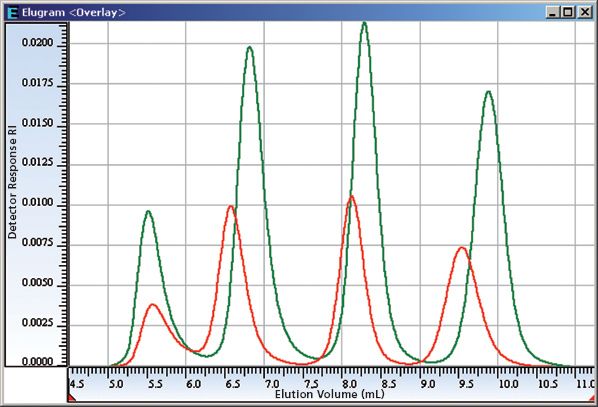

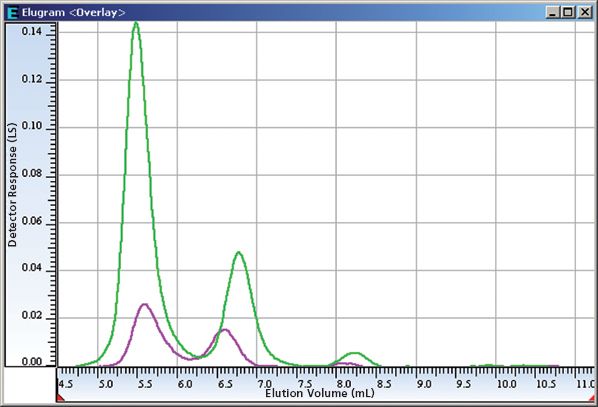

The consequences can be best explained when looking at typical detector signals. Figures 1 and 2 show a raw data comparison of mixtures of four different molar masses for polystyrene (PS) and polymethyl methacrylate (PMMA) in tetrahydrofuran (THF) for an RI detector (Figure 1) and a light-scattering detector (Figure 2, MALLS, 90° only). While concentration and injection volume are the same for both mixtures and the molar masses are comparable, the dn/dc values are very different. Under these conditions PS has a quite high dn/dc of 0.184 mL/g, while the PMMA dn/dc is much smaller at 0.089 mL/g. It is clear from the figures that the signal intensities and peak areas for the PS RI signals are much higher than for PMMA. This is even more pronounced for the light scattering signal because this signal depends on dn/dc.2 It is also important to note that as the dn/dc gets higher, the lower the molar masses that can be detected (under the same analytical conditions).

Figure 1: RI detector signals for a mixture of four different polystyrene molar masses (green trace, dn/dc = 0.184 mL/g) and 4 different polymethyl methacrylate molar masses (red, dn/dc = 0.089 mL/g). Conditions: Peak 1: 0.5 mg/mL, Peak 2–4: 1 mg/mL.

dn/dc values can also be zero or negative, meaning that it is not possible to perform detection with RI/light scattering (dn/dc = 0, sample is isorefractive) or that the RI signal is negative. A well known example of an isorefractive system is polydimethyl siloxane (PDMS) in THF. In this example only small RI signals can be measured because of an end group effect and typical light scattering detection is not possible. One solution is to either replace the RI with an evaporative light scattering detector (ESLD)2 or to switch to using toluene as the solvent and mobile phase. In this case, the dn/dc will be less than zero resulting in negative RI traces.

Figure 2: MALS 90° detector signals for a mixture of four different polystyrene molar masses (green trace, dn/dc = 0.184 mL/g) and four different polymethyl methacrylate molar masses (red, dn/dc = 0.089 mL/g). Conditions: Peak 1: 0.5 mg/mL, Peak 2–4: 1 mg/mL. Molar masses PS/PMMA: 1.2/1.0 MDa, 130/202 kDa, 17.6/18.7 kDa, 1250/2380 Da.

Determining dn/dc Values

There are a number of ways to determine dn/dc, and analysts select a method based on the accuracy and precision required as well as the applicability in the laboratory. The three different general approaches are as follows:

Approach 1: Literature data can be used (if it is available), but it is important that experimental data such as mobile phase, temperature, and wavelength (for example, 635 nm) are identical to the experimental conditions. Good sources for dn/dc data are manuals for light-scattering detectors or general literature.3–5 It is always good practice to verify literature data.

Approach 2: A more accurate method is to measure the dn/dc on-line with the sample using the peak area(s) detected by the RI of the liquid chromatography (LC) equipment. This method is often applied because it is fast, easy-to-use, and does not consume additional sample. This is explained in more detail below.

Approach 3: The most accurate method is to use dedicated batch/stand-alone instrumentation and to measure different concentrations. This requires more time and sample than the on-line method, but is not influenced by chromatographic parameters. Again there is a detailed description below.

Approach 2: On-line dn/dc Determination

In this approach, the measured RI signal area is used to get a dn/dc value, but it can be problematic if the general assumptions that 100% of the sample mass is injected and elutes from the column fail. Also, co-elution of system peaks or additives - because of inefficient separation - can be a problem. According to equation 2, the RI area depends on the sample concentration, the RI detector constant, and the dn/dc value.

The first step is to determine the RI detector constant by injecting at least one sample with a precisely known concentration and dn/dc. It is a prerequisite that all of the sample reaches the detector cell. With this detector constant, and again assuming that all of the injected sample mass reaches the RI detector, the dn/dc can now be determined. The strategies adopted by laboratories are very different with some using only one sample concentration to save time and sample volume, while others inject several concentrations to minimize the experimental error.

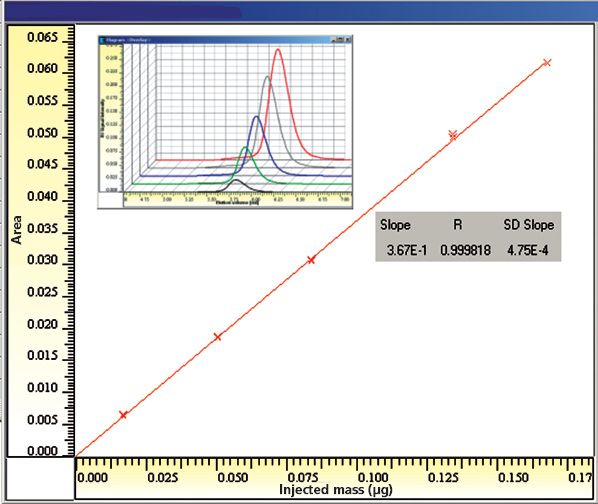

Figure 3 shows an experiment with five different concentrations where the injected mass is plotted vs. area. The dn/dc is determined from the slope, which reflects the detector constant multiplied by the dn/dc. For this approach typical RI detectors are very often used independent of the detector light source type. While there are some RI detectors with a fixed wavelength on the market, many laboratories also use RI detectors successfully with a white light source.

Figure 3: RI peak area plotted vs. the injected mass (concentration, injection volume) for five different concentrations and double injections. The dn/dc can be obtained from the slope, which depends on the RI detector constant and the dn/dc. Insert: Raw data RI detector for five concentrations.

Approach 3: Batch dn/dc Determination with Dedicated Instrumentation

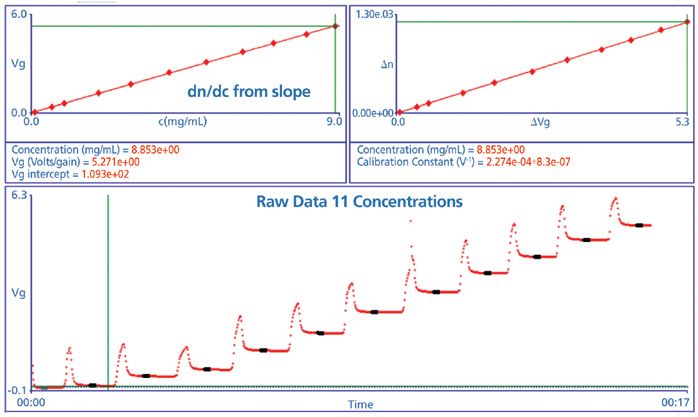

Dedicated stand-alone instrumentation can be used for highly accurate and precise dn/dc values. Most commercial instruments today are deflection-type instruments optimized for convenient batch mode operation, and are available with different wavelengths (red, green, or blue light source) to allow for interpolation of other wavelengths.

Figure 4: dn/dc determination with a dedicated deflection type batch dn/dc instrument (620 nm). Raw data for 11 concentrations and automatic dn/dc determination from slope.

The procedure is comparable to the one using an RI detector. The first step is to calibrate the instrument (determine the detector constant), which is performed using NaCl or KCl solutions. Afterwards the sample dn/dc can be measured by manually injecting five or more concentrations ranging from 0.1 mg/mL to 10 mg/mL.

Summary

- The dn/dc is a crucial parameter for the analysis of stand-alone or on-line light scattering data independent of the method applied (LALS, MALS, RALS).

- dn/dc values can be taken from the literature if the experimental conditions match; however, a verification of the value is highly recommended.

- dn/dc values can be measured on-line with an RI detector, and also in a hyphenated GPC/SEC/gel filtration chromatography (GFC) light-scattering setup. This is a fast approach that often does not require additional sample. It is only applicable if 100% of the sample elutes from the column and requires accurate sample concentrations.

- Most accurate is the off-line approach to measure dn/dc values using dedicated instrumentation, but it also requires more time and sample.

References

1. D. Held and P. Kilz, The Column4(10), 17–20 (2008).

2. D. Held, The Column 9(18), 2–5 (2013).

3. M. Huglin, Ed. Light Scattering from Polymer Solutions (Academic Press, 1972).

4. A. Theisen, C. Johann, M.P. Deacon, and S.E. Harding, Refractive Increment Data-Book for Polymer and Biomolecular Scientists (Nottingham University Press, Nottingham, UK, 2000).

5. J. Brandrup, E. H. Immergut, and E. A. Grulke, Polymer Handbook 4th edition (Wiley, 2003).

Daniela Held studied polymer chemistry in Mainz, Germany, and works in the PSS solutions department. She is also responsible for PSS webinars, education programmes, and customer training.

E-mail: Dheld@pss-polymer.com

Website: www.pss-polymer.com

This information is supplementary to the article “Accelerating Monoclonal Antibody Quality Control: The Role of LC–MS in Upstream Bioprocessing”, which was published in the May 2025 issue of Current Trends in Mass Spectrometry.

Investigating the Protective Effects of Frankincense Oil on Wound Healing with GC–MS

April 2nd 2025Frankincense essential oil is known for its anti-inflammatory, antioxidant, and therapeutic properties. A recent study investigated the protective effects of the oil in an excision wound model in rats, focusing on oxidative stress reduction, inflammatory cytokine modulation, and caspase-3 regulation; chemical composition of the oil was analyzed using gas chromatography–mass spectrometry (GC–MS).

Evaluating Natural Preservatives for Meat Products with Gas and Liquid Chromatography

April 1st 2025A study in Food Science & Nutrition evaluated the antioxidant and preservative effects of Epilobium angustifolium extract on beef burgers, finding that the extract influenced physicochemical properties, color stability, and lipid oxidation, with higher concentrations showing a prooxidant effect.