Reducing HPLC and UHPLC System Noise and Volume with High-Performance Static Mixers

Special Issues

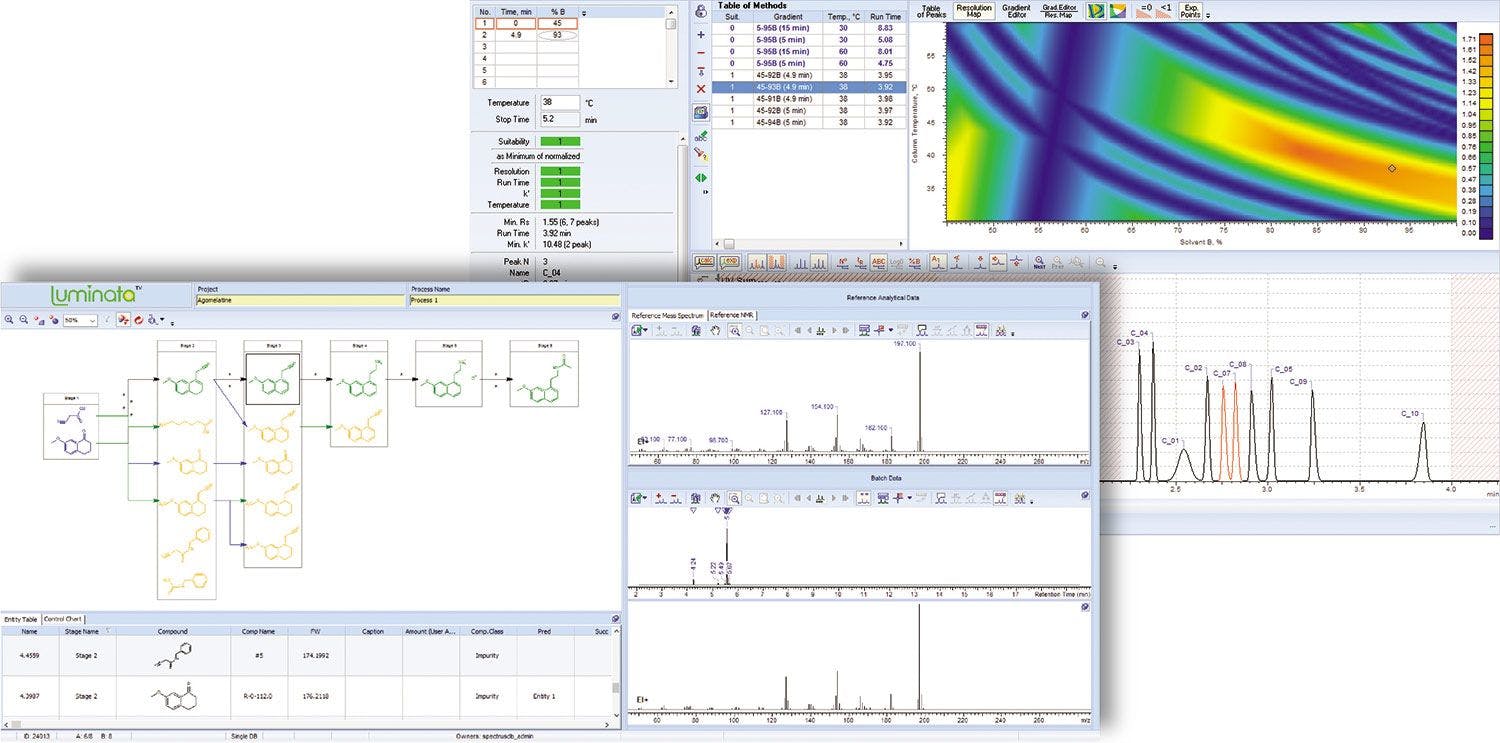

A revolutionary new inline static mixer has been developed and specifically tailored to meet the exacting demands of HPLC and UHPLC systems. Poor mixing of two or more mobile phase solvents results in a high signal to noise ratio and, thus, decreased sensitivity. The test data presented demonstrates that superior mixing is achieved while minimizing the internal volume in various gradient test conditions, such as unparalleled mixing for trifluoroacetic acid (TFA) and water and acetonitrile gradients.

Low mixing efficiency, resulting in poor signal-to-noise ratios, has plagued the chromatography world when it comes to limits of detection and sensitivity. If poor mixing is present, baseline noise will appear as a sine wave (rise and fall) of the detector signal versus time. Poor mixing will also broaden and create asymmetrical peaks resulting in reduced column efficiency and peak resolution. The ideal static mixer will combine the advantages of high mixing efficiency, low dead volume and low pressure drop, while minimizing the volume and maximizing the throughput of the system.

Figure 1: Schematic diagram of the low-pressure gradient experimental test system.

Experimental Conditions

The following HPLC conditions and test setup were employed to measure the system baseline noise and to compare the relative performance of various static mixers. Figure 1 shows a schematic diagram of a typical HPLC and UHPLC system configuration. Static mixer testing was performed by locating the Mott PerfectPeak® static mixer immediately downstream of the pump and upstream of the sample injector and HPLC column. For this study, mixing efficiencies were performed by bypassing the sample injector and column using a capillary tube between the static mixer and the UV detector to create back pressure.

Figure 2: Plots showing offset HPLC UV detector signal versus time for this study showing baseline noise with no mixer, and Mott 25 µL, 50 µL, 100 µL, 150 µL, and 300 µL mixers.

The HPLC system utilized for this testing was an Agilent 1260 Series HPLC with a UV detector controlled using Agilent Chemstation Software. Table I contains the setup conditions used in this study.

Conclusion

This application note demonstrates that greater mixing efficiency is exhibited with every Mott PerfectPeak® static mixer volume increase with respect to the system with no mixer. Greater than 95% reduction in baseline noise was achieved with the largest size mixer which will result in improved limits of detection and sensitivity.

Mott Corporation

84 Spring Lane, Farmington, CT 06032

tel. 1 (860) 747-6333; email: PerfectPeak@mottcorp.com

Website: www.mottcorp.com

Accelerating Monoclonal Antibody Quality Control: The Role of LC–MS in Upstream Bioprocessing

This study highlights the promising potential of LC–MS as a powerful tool for mAb quality control within the context of upstream processing.

Using GC-MS to Measure Improvement Efforts to TNT-Contaminated Soil

April 29th 2025Researchers developing a plant microbial consortium that can repair in-situ high concentration TNT (1434 mg/kg) contaminated soil, as well as overcome the limitations of previous studies that only focused on simulated pollution, used untargeted metabolone gas chromatography-mass spectrometry (GC-MS) to measure their success.

Prioritizing Non-Target Screening in LC–HRMS Environmental Sample Analysis

April 28th 2025When analyzing samples using liquid chromatography–high-resolution mass spectrometry, there are various ways the processes can be improved. Researchers created new methods for prioritizing these strategies.

Potential Obstacles in Chromatographic Analyses Distinguishing Marijuana from Hemp

April 28th 2025LCGC International's April series for National Cannabis Awareness Month concludes with a discussion with Walter B. Wilson from the National Institute of Standard and Technology’s (NIST’s) Chemical Sciences Division regarding recent research his team conducted investigating chromatographic interferences that can potentially inflate the levels of Δ9-THC in Cannabis sativa plant samples, and possible solutions to avoid this problem.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)