GC Temperature Programming—10 Things You Absolutely Need to Know

Temperature affects not only retention but also relative retention in gas chromatography (GC) and therefore, when we change temperature, we also change the selectivity of the separation. This is true as we alter the isothermal separation temperature, but also as we change the slope of the temperature program gradient.

1. Temperature affects not only retention but also relative retention in gas chromatography (GC) and therefore, when we change temperature, we also change the selectivity of the separation. This is true as we alter the isothermal separation temperature, but also as we change the slope of the temperature programme gradient.

2. An increase of around 30 °C in oven temperature will reduce retention time by 50%.

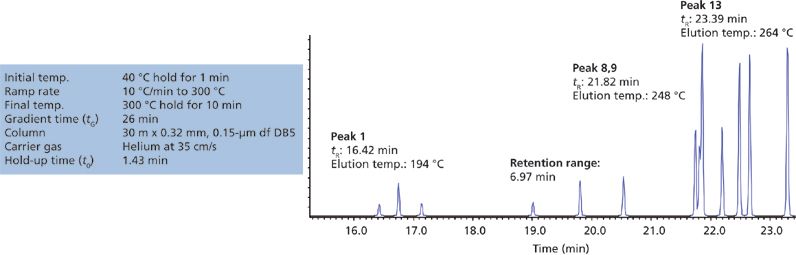

3. Use the method shown in Figure 1 to “screen” samples.

Figure 1: Extract of chromatogram showing all pesticide analyte peaks eluted from a river water extract, analyzed under the screening conditions shown.

4. If the peaks are eluted within a “window” of less than 7 min (more accurately tg/4) then isocratic analysis may be possible (6.97 in our example, so isothermal analysis may be possible)

5. To approximate the required isothermal temperature for the separation, calculate the temperature at which the last analyte of interest is eluted and subtract 45 °C (239 °C in our example).

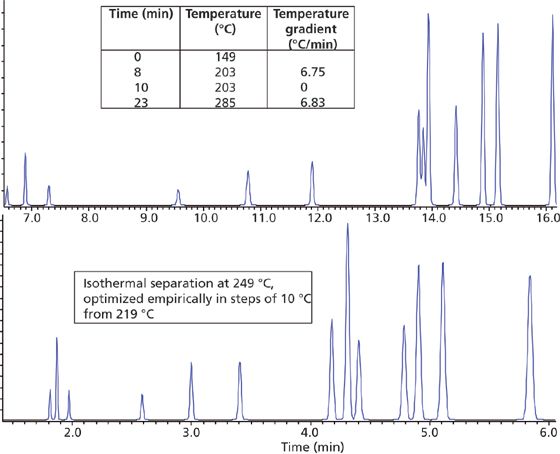

Figure 2: Optimum separations derived from a thermal gradient analysis (top) and an isothermal analysis (bottom).

6. To optimize the separation, alter the isothermal temperature in steps of 10 °C, within a range of ±50 °C. If a suitable separation is not obtained a temperature gradient should be used.

7. For splitless injection, the initial oven temperature should be 20 °C below the boiling point of the sample solvent and an initial hold time of 30 s should be used. For split injection, start with an oven temperature 45 °C lower than the elution temperature of the first peak from the screening chromatogram (149 °C in our exercise). For poorly resolved, early eluted peaks, decrease initial temperature rather than adding an initial isothermal hold unless the initial oven temperature is more than 30 °C below the boiling point of the sample solvent.

8. The optimum ramp rate for any separation can be estimated as 10 °C per hold-up time (7 °C/min in our screening example).

9. If a suitable gradient slope cannot be obtained to separate compounds eluted in the middle of the temperature gradient, insert a midâramp isothermal section at 45 °C below the elution temperature of the critical pair (203 °C to help separate peaks 8 and 9 in our screening example). Empirically determine the length required for the hold (start

with a 1-min hold) and then resume the gradient at the same slope as before.

10. Set the final temperature at 20 °C above the elution temperature of the last analyte in the screen, but bear in mind that a higher temperature “burn” period may be required to elute highâboiling matrix components.

Get the full tutorial at www.CHROMacademy.com/Essentials (free until 20 July)

Understanding FDA Recommendations for N-Nitrosamine Impurity Levels

April 17th 2025We spoke with Josh Hoerner, general manager of Purisys, which specializes in a small volume custom synthesis and specialized controlled substance manufacturing, to gain his perspective on FDA’s recommendations for acceptable intake limits for N-nitrosamine impurities.

University of Rouen-Normandy Scientists Explore Eco-Friendly Sampling Approach for GC-HRMS

April 17th 2025Root exudates—substances secreted by living plant roots—are challenging to sample, as they are typically extracted using artificial devices and can vary widely in both quantity and composition across plant species.

Determining the Serum Proteomic Profile in Migraine Patients with LC–MS

April 17th 2025Researchers used liquid chromatography–mass spectrometry (LC–MS) in their proteomic analysis to compare the serum proteome of migraine patients with healthy controls and to identify differentially expressed proteins as potential migraine biomarkers.