Determination of Pesticides in Banana by AOAC QuEChERS and LC–MS–MS Detection

LCGC Asia Pacific

UCT Application Note

This application note presents a simple and cost-effective method for the fast determination of pesticides in bananas. The method employs the AOAC QuEChERS approach, which yields higher recovery for several sensitive pesticides, such as pymetrozine and Velpar. A 15 g sample of homogenized banana is hydrated with 5 mL of reagent water to give a sample with >80% water. The hydrated sample is extracted using 15 mL acetonitrile with 1% acetic acid, this is followed by the addition of magnesium sulphate and sodium acetate. After shaking and centrifugation, 1 mL supernatant is cleaned in a 2-mL dSPE tube containing 150 mg MgSO4, 50 mg primary secondary amine (PSA), and 50 mg C18. MgSO4 absorbs residual water in the extracts; PSA removes organic acids and carbohydrates; while C18 retains fatty acids and other non-polar interferences. The result is a clean extract for LC–MS–MS analysis.

QuEChERS Extraction

1. Weigh 15 ± 0.15 g of peeled and homogenized banana sample into a 50-mL centrifuge tube (RFV0050CT).

2. Add 5 mL of reagent water to increase the water content in banana from 74% to >80%.

3. Add an internal standard to all samples, and appropriate amounts of pesticide spiking solution to fortified samples.

4. Add 15 mL of acetonitrile with 1% acetic acid.

5. Cap and shake for 1 min at 1000 strokes/min using a Spex 2010 Geno/Grinder.

6. Add salts (6 g MgSO4 and 1.5 g NaOAc) in Mylar pouch (ECMSSA50CT-MP) to each tube, and vortex for 10 s to break up salt agglomerates.

7. Shake for 1 min at 1000 strokes/min using Spex Geno/Grinder.

8. Centrifuge the samples at 3830 rcf for 5 min.

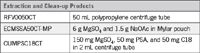

Extraction and Clean-up Products

dSPE Cleanup

1. Transfer 1 mL supernatant into 2-mL dSPE tube (CUMPSC18CT).

2. Shake for 2 min at 1000 strokes/min using Spex Geno/Grinder.

3. Centrifuge at 15300 rcf for 5 min.

4. Transfer 0.3 mL of the cleaned extract into a 2-mL auto-sampler vial.

5. Add 0.3 mL of reagent water, and vortex for 30 s.

6. The samples are ready for LC–MS–MS analysis.

Table 1: Accuracy and Precision Data (n = 5)

LC–MS–MS Method

System: Thermo UltiMate 3000 LC with Vantage MS/MS, ESI+

Injection: 10 μL at 10 °C

LC column: Thermo Accucore aQ, 100 × 2.1 mm, 2.6 μm, at 40 °C

Mobile phase: (A) 0.3% formic acid and 0.1% ammonia formate in water; (B) 0.1% formic acid in methanol

Gradient programme and SRM transitions are available upon request.

Conclusion

A simple, fast, and cost-effective method has been developed for the determination of pesticides in banana samples. Pesticide residues in bananas were extracted using the AOAC version of the QuEChERS approach, followed by dSPE cleanup using MgSO4, PSA, and C18. Excellent accuracy and precision were obtained, even for pymetrozine (recovery >95%), a sensitive pesticide with limited recovery when the original or EN versions of QuEChERS approach is employed. The analytical run time was 20 min and the overall mean recovery for the 24 pesticides tested were 98.7% and 98.9% for the fortified banana samples at 10 ng/g and 50 ng/g, respectively.

UCT, LLC

2731 Bartram Road, Bristol, Pennsylvania19007, USA

Tel: (215) 781 9255

Email: methods@unitedchem.com

Website: www.unitedchem.com

New Method Explored for the Detection of CECs in Crops Irrigated with Contaminated Water

April 30th 2025This new study presents a validated QuEChERS–LC-MS/MS method for detecting eight persistent, mobile, and toxic substances in escarole, tomatoes, and tomato leaves irrigated with contaminated water.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)