Daiso Co. Ltd.

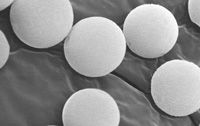

Daiso is one of the world's largest manufacturers of spherical chromatographic-grade silica gel.

Company Description

Daiso is one of the world's largest manufacturers of spherical chromatographic-grade silica gel. The company's high-resolution chromatography products carrying the DAISOGEL brand name are designed for a broad range of applications. Many of the series of products are available in a range of particle and pore sizes and are offered in both analytical and preparative grades. The DAISOGEL products offer selectivities to achieve the separation of the many classes of chemicals encountered by the chromatographer engaged in research, industrial, or pharmaceutical analysis.

Chief Chromatographic Techniques Supported

- Media for chromatography analytical, preparative, and process

- Packing services for preparative column

Markets Served

With the U.S. focus on the demanding pharmaceutical market, Daiso's media must deliver consistent performance from analytical through prep to process in the development and commercialization of drug substances. For this purpose, a new Bio series media was introduced in 2006 to specifically address peptide and protein purification.

Major Products/Services

- Fixed-bed flanged chromatography columns – The homogeneous flow characteristics across the boundaries of the media bed of these columns reduce band broadening and ensure performance that is close to analytical levels.

- Slurry packing service – With 20 years of experience slurry packing preparative chromatography columns using proprietary techniques, Daiso can offer packed columns with guaranteed specifications.

- Bulk media – The company has been supplying bulk chromatographic media to the U.S. market, from 1.7 to 50 micron spherical particles. Great varieties of organic phases are modified at several metric ton scale GMP production completed in the end of 2007.

Facilities

Daiso is now a global business; it has 13 locations in Japan and 4 overseas in the U.S., Europe, and China. International sales are a fast-growing segment of Daiso's business. A new, high-rise building was opened in Osaka in 2006 to provide a larger head office for the growing business.

Daiso Co. Ltd.

1-12-18, Awaza, Nishi-ku, Osaka 550-0011, Japan

Daiso Fine Chem USA, Inc.,

275 Saratoga Avenue, Suite 102, Santa Clara, CA 95050

Daiso Fine Chem GmbH

Immermannstrasse 13, 40210, Duesseldorf, Germany

TELEPHONE

(408) 855-8789

Germany: +49-211-83025168

FAX

(408) 855-8784

Germany: +49-211-83025213

WEB SITE

NUMBER OF EMPLOYEES

Worldwide: 745

YEAR FOUNDED

1915

Analysis of PFAS in Milk by LC-MS/MS

May 15th 2025Dairy milk is one commodity that can be impacted by environmental contaminants, such as PFAS, so it is important to implement extensive, robust, and accurate testing. In this work, a sensitive and reliable method was developed for the analysis of PFAS in milk by LC-MS/MS at levels as low as 0.01 µg/kg.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)