A Compendium of GC Detection, Past and Present

LCGC Asia Pacific

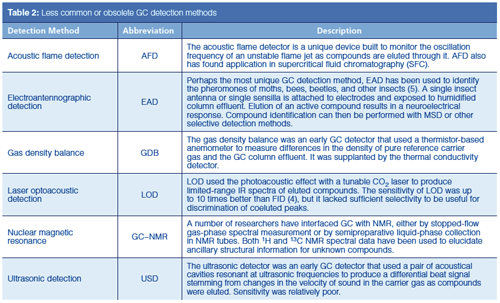

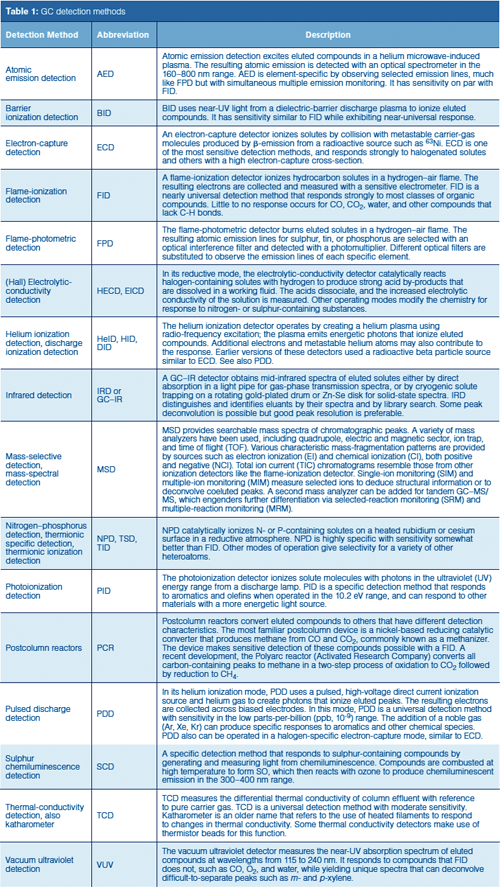

Gas chromatography makes use of a wide variety of detection methods. In addition to the most often used flame-ionization detection (FID), electron-capture detection (ECD), thermal conductivity detection (TCD), and mass-selective detection (MSD), the list of other detection methods is long. They really shine when deployed properly, but their properties and applications can be a bewildering alphabet soup. This instalment presents a compendium of gas chromatography (GC) detection methods, both past and vanished as well as those that are current and relevant to today’s separation challenges.

John V. Hinshaw, GC Connections Editor

Gas chromatography makes use of a wide variety of detection methods. In addition to the most often used flame-ionization detection (FID), electron-capture detection (ECD), thermal conductivity detection (TCD), and mass-selective detection (MSD), the list of other detection methods is long. They really shine when deployed properly, but their properties and applications can be a bewildering alphabet soup. This instalment presents a compendium of gas chromatography (GC) detection methods, both past and vanished as well as those that are current and relevant to today’s separation challenges.

In the six and a half decades since its inception, gas chromatography (GC) has seen a wide variety of detection methods. Four of them arguably account for greater than 90% of applications today (1): flameâionization detection (FID), thermal conductivity detection (TCD), electron-capture detection (ECD), and mass-selective detection (MSD). Many more detectors are found in modern chromatography laboratories in smaller quantities, and a few have found their way into the dusty closet of retirement. Ranging from FID to electroantennographic detection (EAD), which uses insect antennae as the sensing elements, GC detection methods cover a wide range of sensitivity and selectivity that is unsurpassed by any other separation method. In 2015, McNair and Schug, writing in “GC Connections” (2), addressed the history and capabilities of eight major GC detection methods, ranging from TCD to the newest member: vacuum ultraviolet (VUV) detection. Along with these mainstream detection methods, the sheer number that are in active use or have been in the past is remarkable-nearly 30 are listed here in Tables 1 and 2. This is not a comprehensive list. Some chromatographers have chosen to use other names and abbreviations, and certainly other varieties may be found that are not as visible to literature searches.

Detector Taxonomy

The International Union of Pure and Applied Chemistry (IUPAC) recently published updated recommendations regarding separation science terminology (3). The publication defines three general types of chromatographic detector. A universal detector, such as the thermal conductivity detector, responds to any compound in the column effluent that is different than the carrier gas. A specific detector responds only to certain chemically related materials. The electronâcapture detector with halogenated compounds, or the aptly named nitrogen–phosphorus detector with nitrogen or phosphorus compounds, are both specific detectors. Selective detectors respond to groups of compounds that possess a common measurable characteristic such as mass or spectral absorbance. MSD falls into this group along with VUV and infrared detection (IRD or GC–IR).

The boundaries between these classification are not always clearly defined. Flame photometric detection (FPD), for example, responds to selected spectral emission lines of eluted compounds, and might be considered a selective detection method, but the spectral lines are emitted only by molecules containing certain elements, and thus FPD also is a specific detection method. In a practical sense, FPD is used for its element-specific characteristics, not its spectrally selective nature, so it is best considered a specific detection method. The same logic can be applied to other detection methods.

There is no standard for naming chromatographic detection methods. GC detection method names most often reflect modes of selectivity and specificity. FID, photoionization detection (PID), and many others are generally named after their operating principles. NPD, named for its element specificity, has an alias that refers to its physics: thermionic specific detection (TSD). The latter name is broader and encompasses other operating modes of thermionic detection that are sensitive to other heteroatoms.

Scientists have a love–hate affair with acronyms and abbreviations. They are convenient, short, and easy to misuse. Gas chromatographers have their own unique set that fortunately are related almost oneâtoâone with GC devices, detectors, inlets, columns, and so-on. For the new (gas) chromatographer the sheer number of terms is bewildering. Perhaps this list can be of assistance navigating the detector bazaar.

Gas chromatography continues to evolve. Every year new GC-related devices appear in publications and in the marketplace. Three new GC detectors have appeared in recent years-vacuum ultraviolet and barrier ionization detectors, and a postcolumn reaction detector. The bulk of GC detectors continues to see significant application, while only a few have really fallen away into disuse.

References

- Author’s estimate, not based on published data.

- H.M. McNair and K.A. Schug, LCGC North Am.33(1), 24–33 (2015).

- T.A. Maryutina, E.Y. Savonina, P.S. Fedotov, R.M. Smith, H. Siren, and D.B. Hibbert, Pure Appl. Chem. 90(1), 181–231 (2018).

- L.B. Kreuzer, Anal. Chem.50(6), 597A–606A (1978).

- J.A. Byers, J. Neurosci. Methods135, 89–93 (2004).

“GC Connections” editor John V. Hinshaw is a senior scientist at Serveron Corporation in Beaverton, Oregon, USA, and a member of LCGC Asia Pacific’s editorial advisory board. Direct correspondence about this column to the author via e-mail: LCGCedit@ubm.com

Determining the Effects of ‘Quantitative Marinating’ on Crayfish Meat with HS-GC-IMS

April 30th 2025A novel method called quantitative marinating (QM) was developed to reduce industrial waste during the processing of crayfish meat, with the taste, flavor, and aroma of crayfish meat processed by various techniques investigated. Headspace-gas chromatography-ion mobility spectrometry (HS-GC-IMS) was used to determine volatile compounds of meat examined.

Accelerating Monoclonal Antibody Quality Control: The Role of LC–MS in Upstream Bioprocessing

This study highlights the promising potential of LC–MS as a powerful tool for mAb quality control within the context of upstream processing.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)