Climate of Innovation

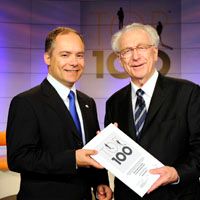

Knauer has been awarded second place in a list of the Top 100 Most Innovative Firms in Germany and placed first in the Climate of Innovation category.

Knauer has been awarded second place in a list of the Top 100 Most Innovative Firms in Germany and placed first in the Climate of Innovation category. According to the company, this is the result of a resourceful workforce and the management’s initiative to create an atmosphere conducive to innovation.

The senior management team around managing director Dr Alexander Bünz and owner Alexandra Knauer claims to have identified communication and cooperation as key factors driving the company’s success and generating a constant flow of ideas. The company reports that the 104 employees submit an average of twelve suggestions for improvements each per year, 80% of which are implemented.

The company also puts these principles of communication and cooperation into practice in an unorthodox way; including team-building cooking sessions, where an interdepartmental team tries its hand at roasting, frying and blanching for its co-workers. A system of job rotation provides employees with better insight into their company and the company claims that flat hierarchies and an open-door policy also nurture the climate of innovation.

Further information on the company, the other 99 prize-winning firms and the Top 100 project can be found at www.knauer.net and www.top100.de

This story originally appeared in The Column. Click here to view that issue.

Measuring Vitamin K1 Concentrations in Dogs with Chronic Enteropathy Using LC–MS/MS

May 14th 2025A joint study between the University of Tennessee (Knoxville, Tennessee) and the University of Pennsylvania School of Veterinary Medicine (Philadelphia, Pennsylvania) compared directly measured vitamin K1 (vitK1) concentrations in healthy dogs and dogs with chronic enteropathy (CE) using liquid chromatography tandem mass spectrometry (LC–MS/MS); they also investigated whether supplementation of vitK1 in dogs with CE would significantly increase vitK1 concentrations.

HPLC 2025 Preview: Fundamentally Speaking (Part 2)

May 14th 2025Michael Lämmerhofer from the Institute of Pharmaceutical Sciences, University of Tübingen, Germany, spoke to JFK Huber Lecture Award winner of 2024 Torgny Fornstedt, professor in analytical chemistry and leader of the Fundamental Separation Science Group, Karlstad University, Sweden, about his pioneering work in high performance liquid chromatography (HPLC) with a focus on fundamentals, ion-pair chromatography, and oligonucleotide applications.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)