Automated Determination Solution Viscosity of Polymeric Materials

The Column

This article introduces the development of an automated and versatile technique for solution viscosity determination of a wide range of polymeric materials in different solvents. Sample preparation is a tedious and error-prone process in viscosity determinations of polymeric materials, especially when elevated temperature or when hazardous solvents are required. This new approach automates sample preparation and injection to the viscometer detector, with benefits in efficiency and safety as well as in analysis precision. The dissolution conditions were studied and optimized to reduce thermal and oxidative degradation, which are detrimental to the accuracy of the observed viscosity.

Alberto Ortín and Pilar del Hierro, Polymer Char, Valencia, Spain

This article introduces the development of an automated and versatile technique for solution viscosity determination of a wide range of polymeric materials in different solvents. Sample preparation is a tedious and error-prone process in viscosity determinations of polymeric materials, especially when elevated temperature or when hazardous solvents are required. This new approach automates sample preparation and injection to the viscometer detector, with benefits in efficiency and safety as well as in analysis precision. The dissolution conditions were studied and optimized to reduce thermal and oxidative degradation, which are detrimental to the accuracy of the observed viscosity.

Determining the solution viscosity of polymeric materials is very important for the research and manufacturing industries because it can be used to estimate the molar mass to provide important information related to the physical properties of polymers. The relative viscosity of a dilute polymer solution to that of the pure solvent itself is measured and from that the intrinsic viscosity (IV or [η]) of the polymer is calculated. The popularity of dilute solution viscosity measurements and the availability of those methods in many manufacturing laboratories has meant that the IV of polymers has traditionally been used to specify and to control the production grades. It must be noted, however, that IV is not a property of the polymer itself, as molar mass is, but rather a property of the polymer solution, influenced by the solvent and temperature.

This article will discuss a recently developed method for viscosity measurements of polymeric materials in solution. It is compatible with organic solvents typically used such as decalin, tetralin, tri-chlorobenzene (TCB), and ortho-dichlorobenzene (o-DCB) among many others. Dissolution temperature and analysis temperature were set independently, from ambient to 200 ºC, so that a wide range of polymers, even the most crystalline ones, can be analyzed with convenience and safety with this approach.

Experimental

The intrinsic viscosity of different polymers was determined using an automated instrument model IVA, Intrinsic Viscosity Analyzer (Polymer Char). Standard operating conditions for polyolefins were: dissolution temperature: 140–160 °C, time: 60–90 min, with gentle shaking under nitrogen atmosphere; measurement flow rate: 3 mL/min, solvent: TCB, concentration: 1 mg/mL. Different conditions for other polymers or analysis are indicated in the text below.

A number of industrial samples of polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) from different manufacturers were analyzed. TCB was used for PE and PP samples, while a mixture of phenol and o-DCB was used for PET. All solvents were filtered before use.

Intrinsic Viscosity Determination

The new method performs the polymer intrinsic viscosity measurement by means of a two-capillary relative viscosity detector, which was developed and patented by Yau in the 1980s (1), as a robust method in contrast to temperature, pressure, or solvent flow rate variations.

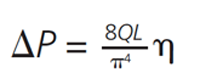

Capillary viscometers rely on the principle that under a forced flow (Q), the pressure drop (âP) from a fluid traveling along a capillary tubing of length L and radius r is proportional to the absolute viscosity of the flowing fluid (η), according to Poiseuille’s law:

(1)

Absolute viscosity of fluids is important to many industries and can be measured using a variety of different viscometers. However, in polymeric materials the interest is on the relative viscosity of a dilute polymer solution compared to that of the pure solvent, given that from it, the intrinsic viscosity, which is related to the molar mass of the polymeric material, can be derived.

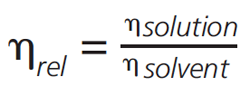

In the first place, the relative viscosity (ηrel) is defined as:

(2)

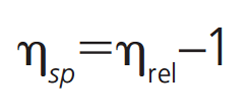

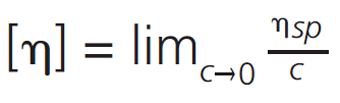

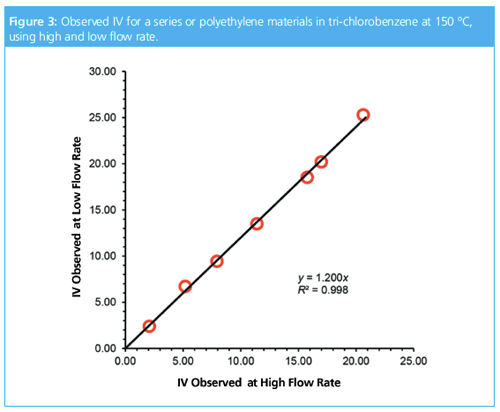

This is a dimensionless quantity that represents to what extent the added polymeric material increases the viscosity of the solvent. The relative viscosity of the solution is proportional to the amount or concentration (C) of polymer it contains, while the intrinsic viscosity is independent of concentration. The specific viscosity (ηsp) of the solution and the polymer intrinsic viscosity are calculated according to the following equations:

(3)

(4)

The intrinsic viscosity has units of inverse density (dL/g for instance). It is defined at the limit of infinite dilution (zero concentration), and is sometimes calculated by extrapolation of data at different concentration levels. A more practical and efficient approach is based on a single-point relative viscosity measurement, taken at a defined concentration low enough to eliminate the need for extrapolation, or using a model equation to estimate the extrapolated value. Among several models and equations, the Solomon-Ciutà equation, which does not require additional parameters, can be used:

(5)

Results and Discussion

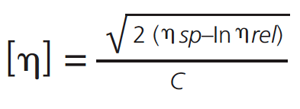

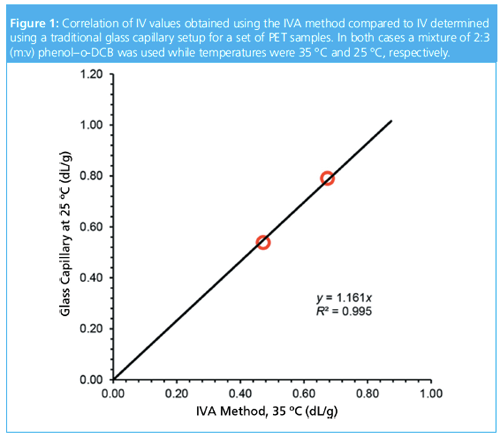

Different polymers in various solvents have been analyzed using this method, including PAN (polyacrylonitrile) in N,N-dimethylformamide (DMF), PET in phenol–o-DCB, polylactic acid (PLA) in TCB, and polyolefins in TCB and o-DCB. Even if the procedure or conditions using this system were different, the IV results obtained were in good agreement with reference methods (ISO 1628-3:2010 f.i.) in all cases, as shown in Figures 1 and 2 for two of the systems considered.

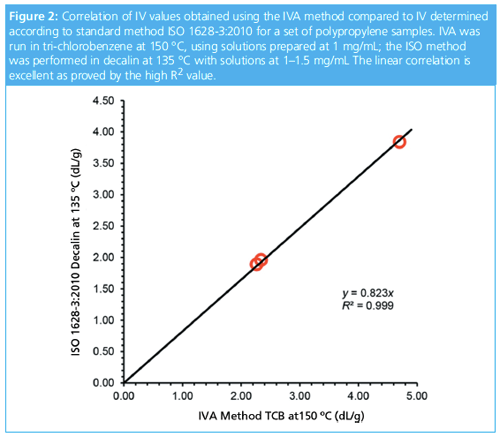

A factor to keep in mind when comparing different methods to evaluate IV in polymeric materials is the effect of shear rate on the observed viscosity. Methods based on glass capillaries are driven by gravity and operate under low shear condition, while forced flow, used in this new method, may work at higher shear rates. Typically when shear rate increases the observed viscosity decreases, so keeping constant shear rate may be advantageous to obtain consistent results.

A study was conducted for a set of PE materials spanning a very wide range in IV, in order to compare the observed viscosity at two different flow rates. Results depicted in Figure 3 show that an excellent correlation was found, and therefore a high flow rate determination was performed to reduce the analysis time, and still obtain data comparable to lower shear conditions. The analysis time for each sample was reduced from 30 min to 4 min with the increased flow rate.

Intrinsic Viscosity of UHMWPE: Maybe one of the most challenging polymers for analysis is ultra-high molar mass polyethylene (UHMWPE). These are high crystallinity materials with extremely high values of IV and are only soluble at elevated temperatures in organic solvents. Special care must be taken in sample preparation to prevent degradation, which would reduce the apparent viscosity, and also in the analysis, given the high viscosity of the solutions.

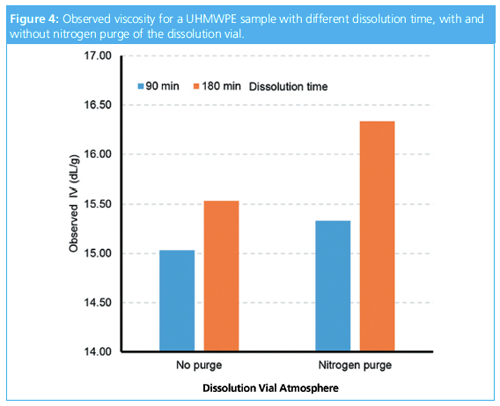

Dissolution temperature and time must be chosen so that the polymer dissolves completely but also to give the very long molecular chains enough time to disentangle completely and obtain reliable viscosity values. In Figure 4, data collected after 90 min or 180 min of dissolution show that longer time is required to achieve that full disentanglement condition; otherwise, the intrinsic viscosity is underestimated. When the polymer stays at elevated temperature for such long time, a nitrogen atmosphere is also required to prevent oxidative degradation, which also decreases the observed viscosity (Figure 4).

An infrared (IR) detector can be optionally used for online accurate quantification of the injected mass, which otherwise needs to be entered as weighed using an analytical balance. The IR detector is suitable for detection of polymers with aliphatic CH groups, dissolved and analyzed in solvents that are IR transparent, such as the important class of polyolefins (polyethylene, polypropylene, and copolymers), in TCB or o-DCB

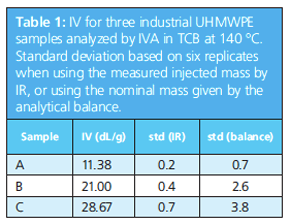

To demonstrate the advantage in precision when applying online IR quantification compared to the offline balance, three different high molar mass PE materials were analyzed at a low concentration level of 0.25 mg/mL or 0.15 mg/mL in TCB. Dissolution time was 1 h with gentle shaking, at 140 ºC under nitrogen atmosphere to reduce thermal and oxidative degradation. Results are presented in Table 1, together with standard deviation, when using the IR detector for quantifying the injected mass, and when using the nominal weight given by the analytical balance, in the IV calculation. An improvement in the precision is clearly seen when the actual mass measured by the IR detector is considered, because this eliminates any errors associated with handling small amounts of polymer by the operator, but also as a result of the possible presence of nonsoluble particles.

Conclusions

A new method has been developed for dilute solution viscosity that is proven to be efficient, precise, and safe. A wide range of polymers soluble from ambient to 200 ºC can be analyzed in a variety of solvents. This method is a precise and convenient approach to IV measurement because of the automation of all the analytical procedures.

The proposed method takes an automated approach and performs all the required steps without user intervention nor solvent handling throughout the whole process, paying special attention to the sample condition, minimizing the degradation, as well as to laboratory health and safety considerations. Appropriate dissolution time control and purging of the vial atmosphere with nitrogen both help in enhanced reliability of the data, by reducing degradation possibilities. The application of a fixed forced flow rate for the IV determination may also help in improving consistency of data by keeping constant shear in all determinations, while increased flow rate provides a net gain in efficiency and maintaining good correlation of the method with lower shear values.

When applicable, the online IR detection helps in improving the accuracy and precision of the method, through the direct quantification of the true amount of sample injected.

References

- W.W. Yau, U.S. patent 4,793,174, 5 October 1987.

Alberto Ortín received his M.Sc in analytical chemistry and a Ph.D. in chemistry from the University of Valencia, Spain. He is currently a scientist at Polymer Char and his research interests include the implementation of new polyolefin characterization technologies and advanced detection methods.

Pilar del Hierro has a degree in chemistry from the University in Valencia, Spain. She holds a masters degree in polymer science from the Science and Technology Institute for Polymers in Madrid, Spain, and a Ph.D. in chemistry from the University of Valencia. In 2001, she joined Polymer Char where she has been working in the analytical department and is involved in the development of quality control (QC) instrumentation.

E-mail:info@polymerchar.comWebsite:www.polymerchar.com

Characterizing Plant Polysaccharides Using Size-Exclusion Chromatography

April 4th 2025With green chemistry becoming more standardized, Leena Pitkänen of Aalto University analyzed how useful size-exclusion chromatography (SEC) and asymmetric flow field-flow fractionation (AF4) could be in characterizing plant polysaccharides.

Investigating the Protective Effects of Frankincense Oil on Wound Healing with GC–MS

April 2nd 2025Frankincense essential oil is known for its anti-inflammatory, antioxidant, and therapeutic properties. A recent study investigated the protective effects of the oil in an excision wound model in rats, focusing on oxidative stress reduction, inflammatory cytokine modulation, and caspase-3 regulation; chemical composition of the oil was analyzed using gas chromatography–mass spectrometry (GC–MS).