Analysis of Accutrace Plus Marker in Fuels with GC–MS

In January 2024, a new Accutrace™ Plus fuel marker BPE (butyl phenyl ether) replaced the previous “Solvent Yellow 124” standard in the European Union. Consisting of naphthenic hydrocarbons as solvent and BPE, the new marker is laundering-resistant, contains no harmful additives and is easy to handle. Moreover, it can be detected quickly using gas chromatography–mass spectrometry (GC–MS) at extremely low levels. A new method has been developed to provide a sensitive, accurate and convenient GC–MS method to align with the new European regulation.

Since 2001, a common fuel marker has been used in the European Union (EU) as a fiscal marker to avoid not only confusion of differently taxed fuels and diesel but also to detect fuel fraud, dilution, adulteration and theft that leads to a loss of tax revenue for governments and oil companies in the EU of several billion EUR each year. In many European countries, fuels such as agricultural diesel, mineral diesel and heating oil are subsidized. To combat the misuse of the lower tax fuels, they were historically marked with different azo dyes called “Solvent Red”. The yellow marker “Solvent Yellow 124” was established for heating oil EU-wide from 2002 because it was easier to analyze. Under the name “Euromarker” it is added to fuels not intended for motor vehicles in amounts of 6 mg/L. Solvent Yellow 124 itself hardly colors the fuel oil, so a red dye is also added for easy differentiation. It can be detected very quickly and sensitively with an indicator reagent even when strongly diluted; alternatively it can be quantified using high performance liquid chromatography (HPLC). However, the last review from the European commission showed that Solvent Yellow 124 is not that robust against common removal techniques (1). Smart cheaters even found a way for “fuel laundering” (2).

Resistant to Laundering

Furthermore, some European countries expressed concerns about the toxicity of azo dyes (3). Consequently, the European Commission decided to adopt Accutrace Plus as a new, safer and more robust Euromarker. The new marker BPE (butyl phenyl ether) is laundering-resistant, contains no harmful additives and is easy to handle. Moreover, it can be detected quickly using GC–MS at extremely low levels. The decision for the use of the Accutrace Plus fuel marker was implemented in January 2024.

Experimental Instrumental Setup:

A GCMS 2020 NX GC instrument with an FID-2030 detector and AOC 30i autosampler was used (Shimadzu). Stationary phases used were DB-17HT, 15 m × 0.25 mm × 0.15 μm (Shimadzu); and VF-WAXms, 30 m × 0.25 mm × 1.0 μm (Shimadzu) and a retention gap with dimensions 2 m × 0.15 mm (Shimadzu). GCMS Solution and GCMS Insight Software (Shimadzu) was used to analyse the data.

Sample Preparation and Calibration:

A stock solution of BPE in xylene was used to prepare a 7-point calibration between 0.1 mg/L and 12 mg/L in diesel. The samples were analyzed directly without any sample preparation. Thanks to the heart-cut technique, most of the fuel matrix was transferred to the flame-ionization detector and only a very small part of the sample, containing the BPE, was directed to a second, polar column and finally to the GC–MS system equipped with an FID detector and an autosampler. After introducing the BPE into the MS, the higher boiling compounds were removed from the first column by backflushing the system, hereby reducing contaminations, prolonging the cleaning intervals of the ion source and reducing the total analysis time.

Results

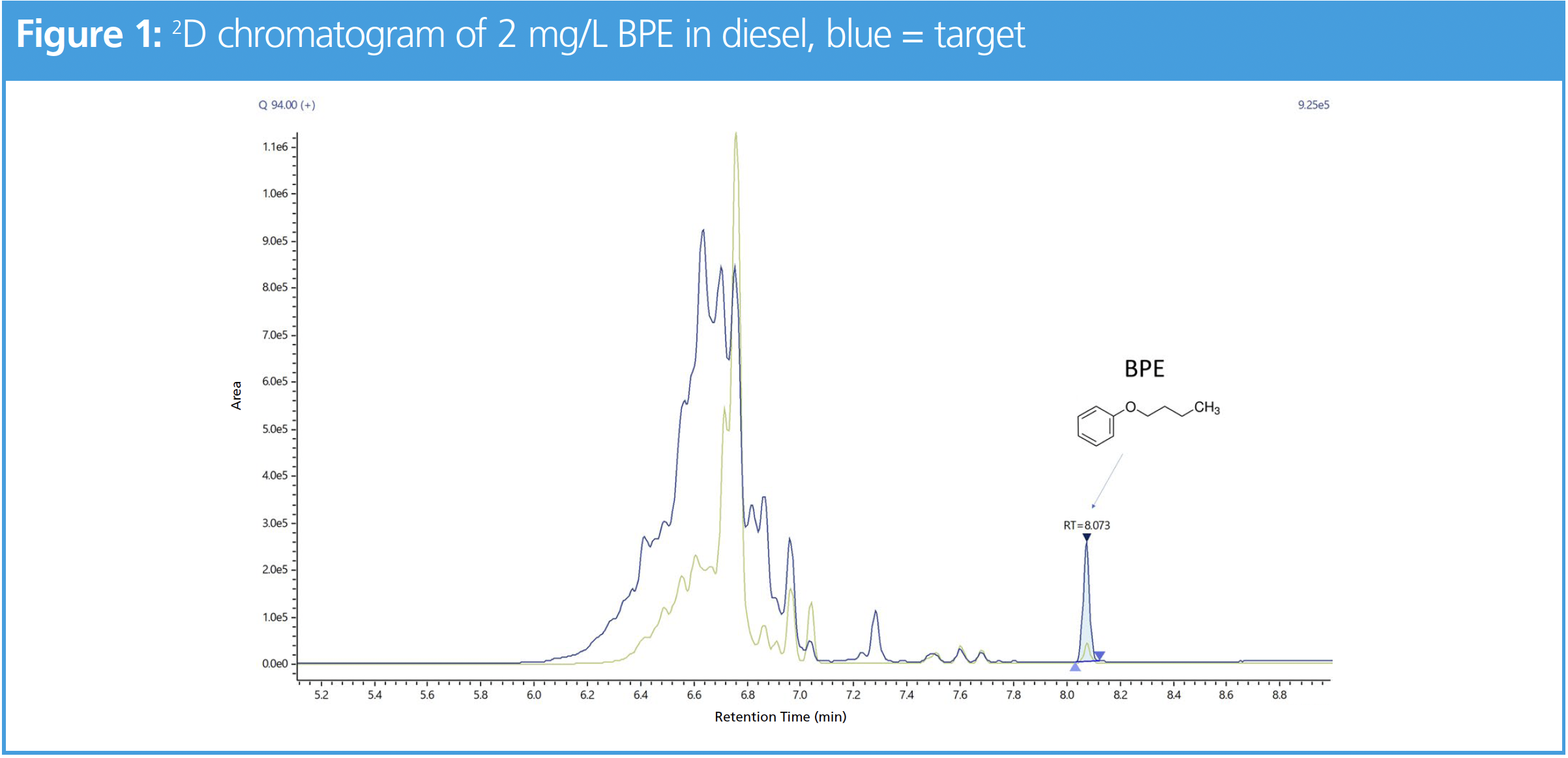

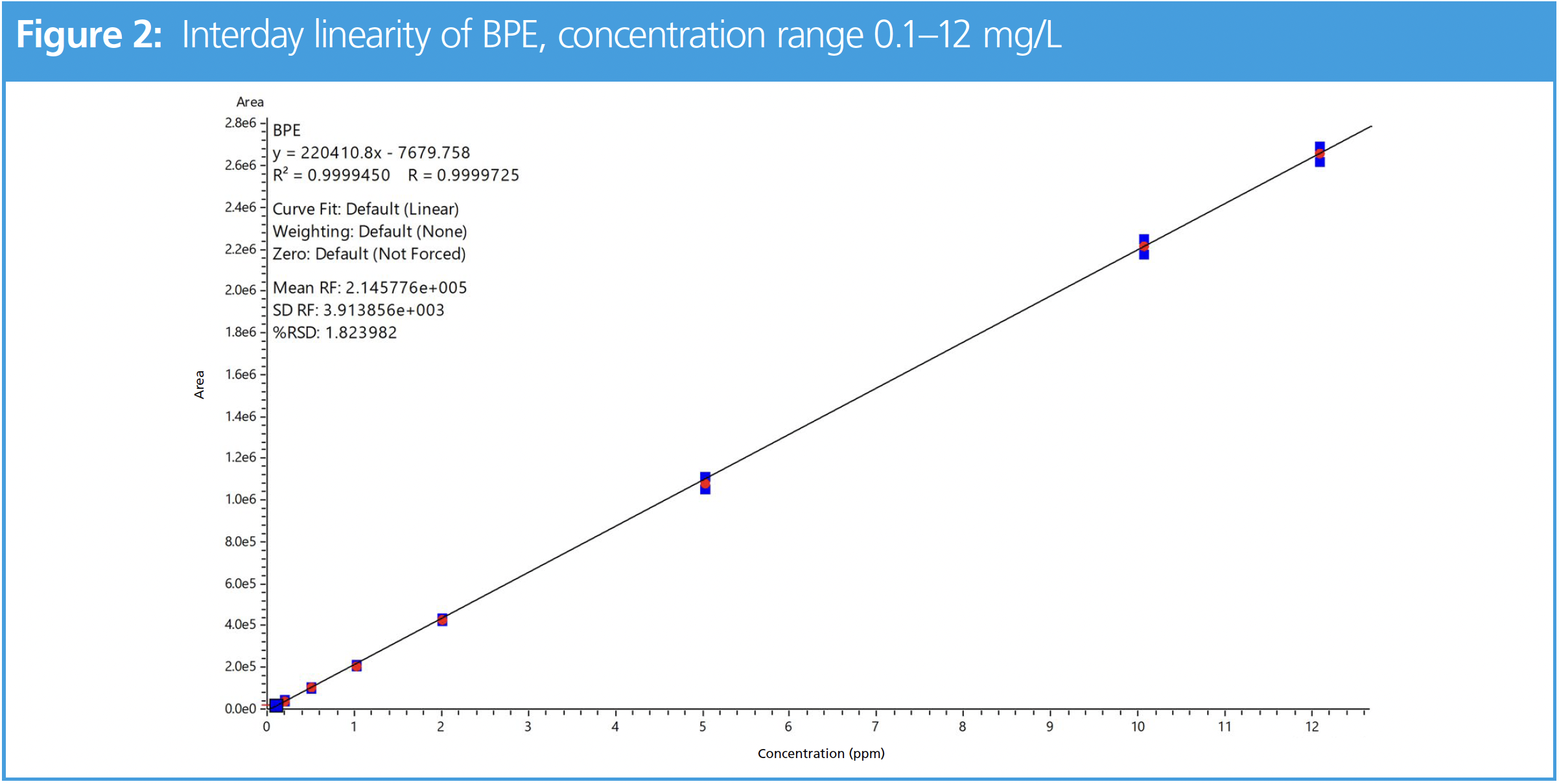

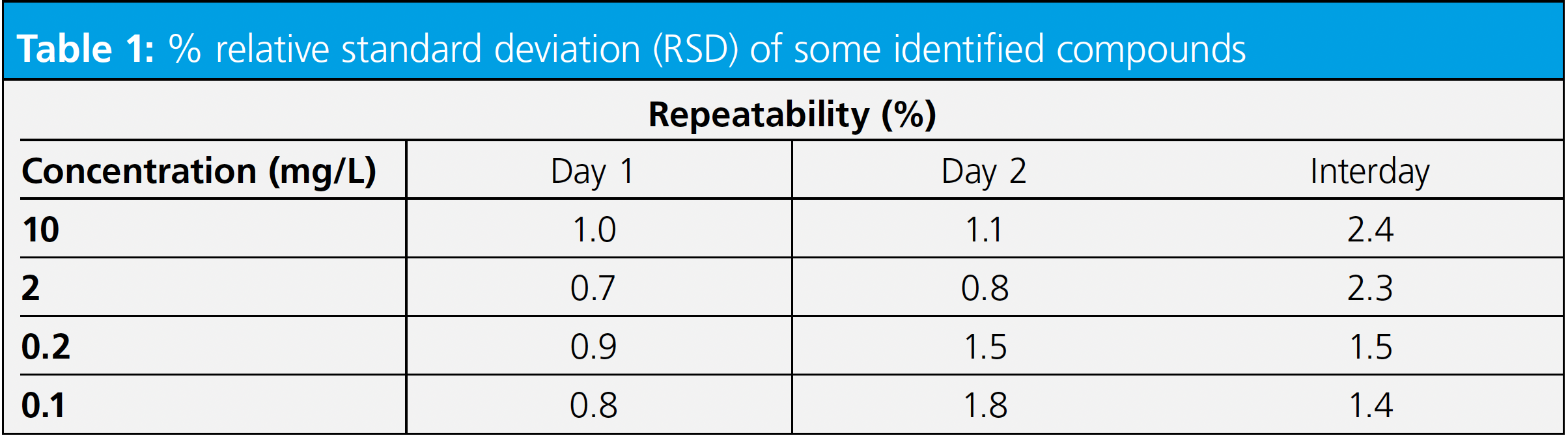

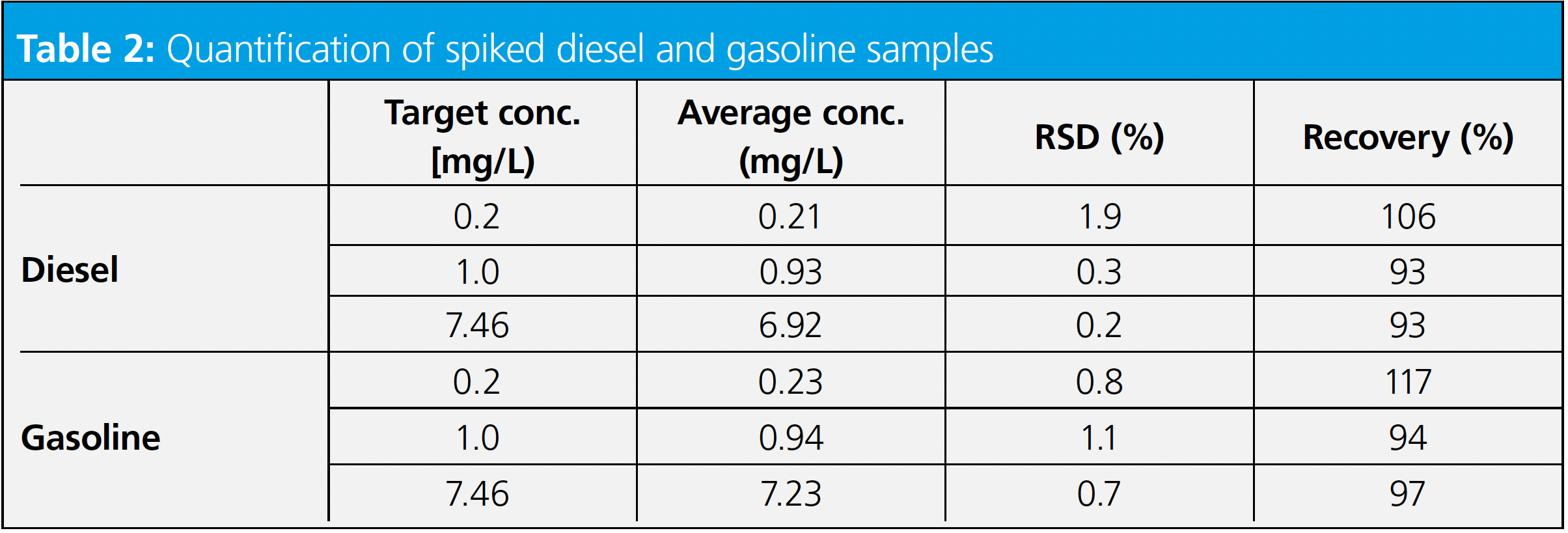

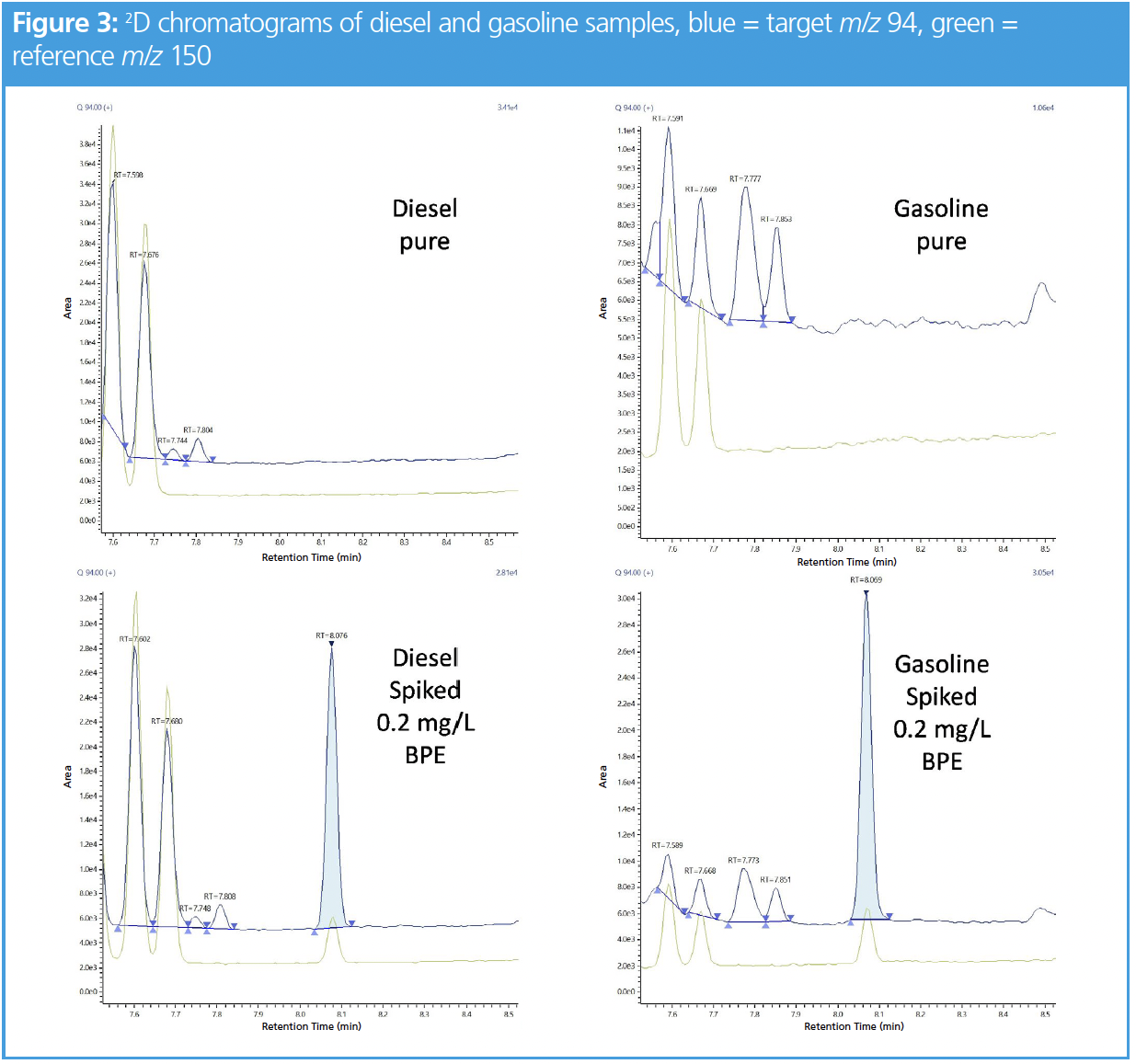

A representative second dimension (2D) chromatogram of BPE in diesel, showing baseline separation of BPE from diesel, can be seen in Figure 1. Excellent linearity was observed within the tested concentration range between 0.1 and 12 mg/L in two consecutive days, with a correlation coefficient (R2) >0.9999, as can be seen in Figure 2. The limits of detection and quantification (LOD and LOQ, respectively) were calculated based on the signal-to-noise ratio (S/N) using five replicates of the lowest BPE standard (100 μg/L). An LOD of 2.8 μg/L and an LOQ of 9.2 μg/L were achieved, allowing a detection of adulterated diesel far below the requested quantification limit. To study the repeatability of the method, five consecutive injections of different BPE concentrations in diesel were performed over two days. At the lowest BPE concentration of 0.1 mg/L, an intraday repeatability of 0.8% on day 1 and 1.8% on day 2 were observed, resulting in an interday repeatability of 1.4%. The results for all concentration levels are shown in Table 1. Recoveries between 93% and 117% were calculated in spiked diesel and gasoline samples, as can be seen in Table 2. Finally, the 2D selective ion monitoring (SIM) chromatograms of spiked diesel and gasoline samples were compared (see Figure 3). It can be observed that in both spiked samples, BPE is well separated from the matrix.

Conclusions

This technique offered reduced total analysis time, less downtime, and increased overall throughput. The use of GC–MS with FID enables the successful determination of BPE in diesel and gasoline. Thanks to this heart-cut system, not only is the separation of the polar BPE from the non-polar fuel achieved but the method can also be successfully validated. Furthermore, using this system results in a lower matrix fraction, reaching the 2D and MS and therefore a drastically reduced ion source contamination. It also minimizes the total analysis time by allowing to backflush at the same time as the separation takes place in the 2D. Because the system is more robust and the ion source needs to be cleaned less often, the downtime of the system is significantly reduced, increasing the overall throughput.

References

(1) https://app.lexploria.com/document/119352-commission-implementing-decision-eu-2022197-of-17-january-2022-establishing-a-common-fiscal-marker-for-gas-oils-and-kerosene-notified-under-document-c2022-74 Zadora, G. Laundering of “Illegal” Fuels – A Forensic Chemistry Perspective. Acta Chim. Slov. 2007, 54, 110–113. https://acta-arhiv.chem-soc.si/54/54-1-110.pdf (accessed 2024-01-26).

(2) Environment and Climate Change Canada, Health Canada, Government of Canada. Screening Assessment: Aromatic Azo and Benzidine-based Substance Grouping: Certain Azo Solvent Dyes, May 2016. https://www.researchgate.net/profile/Hanna-Hamid/post/Fuel-dyes-Are-they-harmful-to-aquatic-biota-and-aquatic-environment/attachment/5db89d8bcfe4a777d4eb5228/AS%3A819435447255040%401572380043225/download/FSAR_Grouping-Azo-Pkg2-Azo+Solvent+Dyes_EN.pdf (accessed 2024-01-26).

Dr. Waldemar Weber, Product Manager GCMS, Shimadzu Europa GmbH; Nerea Lorenzo Parodi, Product Specialist GCMS, Shimadzu Europa GmbH; Dr. Ute Potyka, Product Specialist GCMS, Shimadzu GmbH; and Xaver Mönnighoff, Shimadzu, GmbH.

Fundamentals of Benchtop GC–MS Data Analysis and Terminology

April 5th 2025In this installment, we will review the fundamental terminology and data analysis principles in benchtop GC–MS. We will compare the three modes of analysis—full scan, extracted ion chromatograms, and selected ion monitoring—and see how each is used for quantitative and quantitative analysis.

Characterizing Plant Polysaccharides Using Size-Exclusion Chromatography

April 4th 2025With green chemistry becoming more standardized, Leena Pitkänen of Aalto University analyzed how useful size-exclusion chromatography (SEC) and asymmetric flow field-flow fractionation (AF4) could be in characterizing plant polysaccharides.