An Alternative to Classical SPME: SPME Arrow for the Analysis of Flavour Profiles

SPME Arrow offers higher adsorption capacity and higher mechanical robustness than traditional solid-phase microextraction (SPME). Traditional SPME also has a small linearity range. In this article, an SPME Arrow fibre and classical SPME fibre were tested for the analysis of flavour profiles for different types of beverages.

ZoomTeam/stock.adobe.com

SPME Arrow offers higher adsorption capacity and higher mechanical robustness than traditional solid-phase microextraction (SPME). Traditional SPME also has a small linearity range. In this article, an SPME Arrow fibre and classical SPME fibre were tested for the analysis of flavour profiles for different types of beverages.

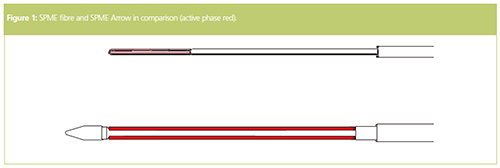

Solid-phase microextraction (SPME) is one of the most important sample extraction techniques in routine analysis (1–3). However, the fibres used are also known for being susceptible to mechanical stress and offer a small linearity range due to the limited sorption phase (1,4). The new SPME Arrow offers bigger adsorption capacity and higher mechanical robustness (Figure 1) and is therefore a very promising alternative to overcome these issues (5).

The novel solid-phase microextraction was evaluated by several R&D groups in cooperation with CTC Analytics, who owns the patent on this technique (5). Typical application fields of SPME Arrow are identical to SPME, and the traditional SPME sorbents such as polydimethylsiloxane (PDMS), acrylate, and carbon WR were adapted to the Arrow to allow for use in the majority of classical SPME applications, such as volatile organic compounds (VOCs) and polycyclic aromatic hydrocarbons (PAHs) in water and soil analysis.

The present study shows SPME Arrow and classical SPME fibre coated with carbon WR in the analysis of flavour profiles for different types of beverages.

Experimental

Sample Preparation: A series of 18 mL measurements of raw beverages (caffeinated retail lemonade and homeâmade apple juice) were filled into a 20-mL vial without further preparation or dilution.

Sample Extraction: Sample extraction with a Shimadzu AOC-6000 autosampler was done fully automatically using SPME Arrow and SPME fibres, respectively. Immersion was performed using the following parameters.

Gas Chromatography–Mass Spectrometry (GC–MS) Analytical Conditions:

System configuration: GC–MS: GCMS QP 2020 NX (Shimadzu); injector: SPL2010 for Arrow (CTC Analytics AG); column: 20 m × 0.18 mm, 0.18-μm (Shimadzu).

Analytical conditions AOC-6000: Injection mode: Split 1:10 to 1:200; injector temperature: 240 °C; fibre type: SPME Arrow/SPME; adsorption material: carbon WR; preâincubation time: 5 min; extraction time: 30 min; extraction temperature: 40 °C; stirring speed 1600 rpm; desorption time: 2 min; desorption temperature: 240 °C.

Analytical conditions GC: Column oven temperature: 40 °C (2.5 min) " (20 °C/min) " 240 °C (5 min); flow control mode: linear velocity (40 cm/s); carrier gas: helium.

Analytical conditions MS: Transfer line: 200 °C; ion source: 200 °C; emission current: 150 µA; ionization mode: EI, 70 eV; loop time: 0.30 s; acquisition mode: scan (50–400 amu).

A sufficient mass transfer during immersion was ensured by use of constant vial shaking with the HeatEx stirrer (CTC Analytics AG). As all samples contained significant amounts of sugar, fibres were washed for 0.1 min in ultrapure water directly after adsorption.

Sample Measurement: Sample measurement was performed using a GCMS-QP2020 NX high-end single quadrupole mass spectrometer (Shimadzu) equipped with the AOCâ6000 (Shimadzu) for automatic sample introduction. SPME Arrow or SPME fibres were introduced after immersion into a split injector for desorption. Identical GC–MS parameters were applied with both types of SPME for a real comparison of sampling technique.

Results

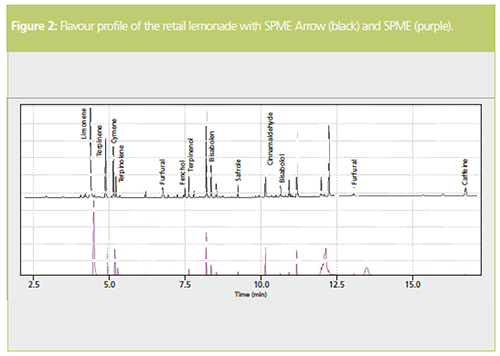

Sensitivity: Figure 2 shows improved extraction efficiency for nearly all flavour compounds in the retail lemonade with SPME Arrow. Some were only detectable with SPME Arrow. Measurements were done at high split ratio (1:200) to prevent detector saturation for highly concentrated compounds.

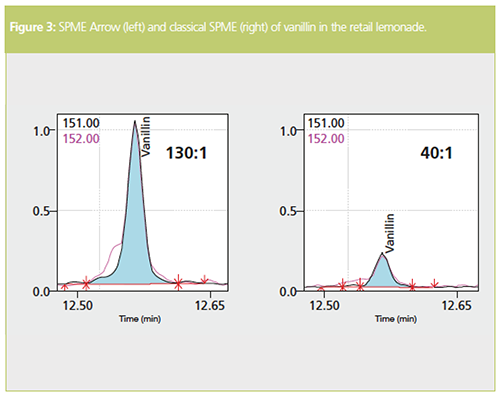

Figure 3 shows differences in sensitivity for vanillin in the retail lemonade measured at split ratio 1:10. An increase of signal-to-noise (S/N) from 40:1 in classical SPME to 130:1 in SPME Arrow is evident.

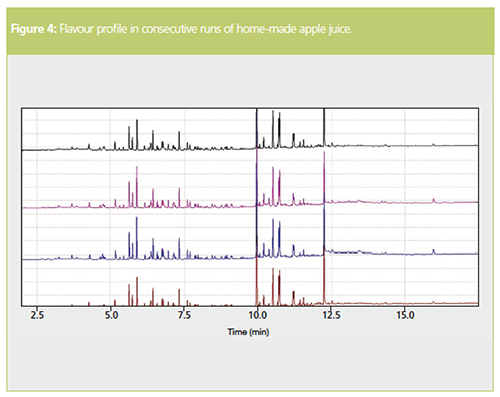

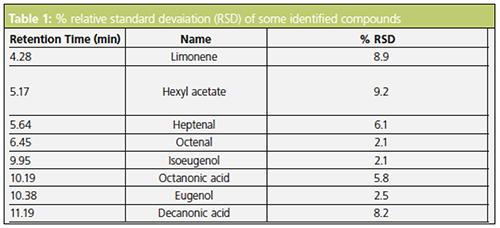

Reproducibility: A home-made apple juice was used for investigation of reproducibility. Figure 4 shows four consecutive runs using SPME Arrow. A very good stability of the flavour profiles is evident. Some representative % relative standard deviation (RSD) values are summarized in Table 1.

Conclusion

Both techniques were effective at identifying VOCs. The SPME Arrow method was more sensitive for method recovery as well as for some additional compounds not found by SPME. However, this sensitivity means that the SPME Arrow method is more susceptible to column bleed as well as phthalates from septum bleed. As a result of increased sensitivity, the SPME Arrow can be used for applications where low detection limits are necessary, but it could also be used for applications with long sample preparation periods. The increased size of the stationary phase would allow the Arrow fibre to produce the same sensitivity as a traditional fibre in less time.

References

- A. Spietelun, A. Kloskowski, W. Chrzanowski, and J. NamieÅnik, Chem. Rev. 113(3), 1667–1685 (2012).

- J. Laaks, M.A. Jochmann, and T.C. Schmidt, Anal. Bioanal. Chem. 402(2), 565–571 (2012).

- M.S. García-Falcón, B. Cancho-Grande, and J. Simal-Gándara, Water Res. 38(7), 1679–1684 (2004).

- H. Bagheri, H. Piri-Moghadam, and M. Naderi, TrAC Trends Anal. Chem. 34, 126–139 (2012).

- A. Kremser, M.A. Jochmann, and T.C. Schmidt, Analytical and Bioanalytical Chemistry 408, 943–952 (2016).

Waldemar Weber began his study as a chemist in 2005 at the University of Münster, Germany. After graduation, he obtained his Ph.D. at the University of Münster in 2011, and finished as a postdoc in 2013 at the Research Center ‘MEET’ in Münster, Germany. From 2012 to 2013, he was employed as an application specialist at JAS in Moers, Germany. In November 2018 he joined Shimadzu Europa as Product Manager for

GC–MS.

New Study Reviews Chromatography Methods for Flavonoid Analysis

April 21st 2025Flavonoids are widely used metabolites that carry out various functions in different industries, such as food and cosmetics. Detecting, separating, and quantifying them in fruit species can be a complicated process.

Analytical Challenges in Measuring Migration from Food Contact Materials

November 2nd 2015Food contact materials contain low molecular weight additives and processing aids which can migrate into foods leading to trace levels of contamination. Food safety is ensured through regulations, comprising compositional controls and migration limits, which present a significant analytical challenge to the food industry to ensure compliance and demonstrate due diligence. Of the various analytical approaches, LC-MS/MS has proved to be an essential tool in monitoring migration of target compounds into foods, and more sophisticated approaches such as LC-high resolution MS (Orbitrap) are being increasingly used for untargeted analysis to monitor non-intentionally added substances. This podcast will provide an overview to this area, illustrated with various applications showing current approaches being employed.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)