AI-Powered Precision for Functional Component Testing in Tea Analysis

Analyzing functional foods reveals numerous health benefits. These foods are rich in bioactive compounds that go beyond basic nutrition, boosting the immune system and improving overall wellness. However, analyzing these compounds can be challenging. This article discusses AI algorithms to support automated method development for liquid chromatography, simplifying the process, enhancing labor efficiency, and ensuring precise results, making it accessible to non-experts for tea analysis.

Analyzing functional foods unveils a wealth of health benefits as these foods are replete with bioactive compounds that extend beyond basic nutrition. Regular consumption of functional foods can strengthen immunity, reduce the risk of chronic diseases and enhance overall wellness. For example, green tea catechins are renowned for their antioxidant properties and their potential to regulate blood glucose levels, thereby contributing to diabetes prevention. Additionally, certain specialized catechins have anti-allergic properties, alleviating symptoms of hay fever. Similarly, theaflavins found in black tea provide anti-inflammatory and antioxidant benefits that support cardiovascular health and mitigate heart disease risk. However, the analysis of these functional compounds poses significant challenges, often requiring deep expertise in chromatography and involving labor-intensive methods. This article describes the benefits of software-supported method development for this purpose. The use of AI algorithms allows to automate the optimization of liquid chromatography (LC) methods, thereby greatly simplifying the process and facilitating precise quantitative analysis of functional components like catechins and theaflavins in different types of tea. By automating formerly manual tasks, the software enhances labor efficiency and achieves high-precision results, making it accessible even to those without specialized knowledge in chromatography. AI-powered method development is set to transform food analysis, significantly contributing to research and quality control by promoting efficiency and enabling more robust scientific discourse in the field.

Experimental

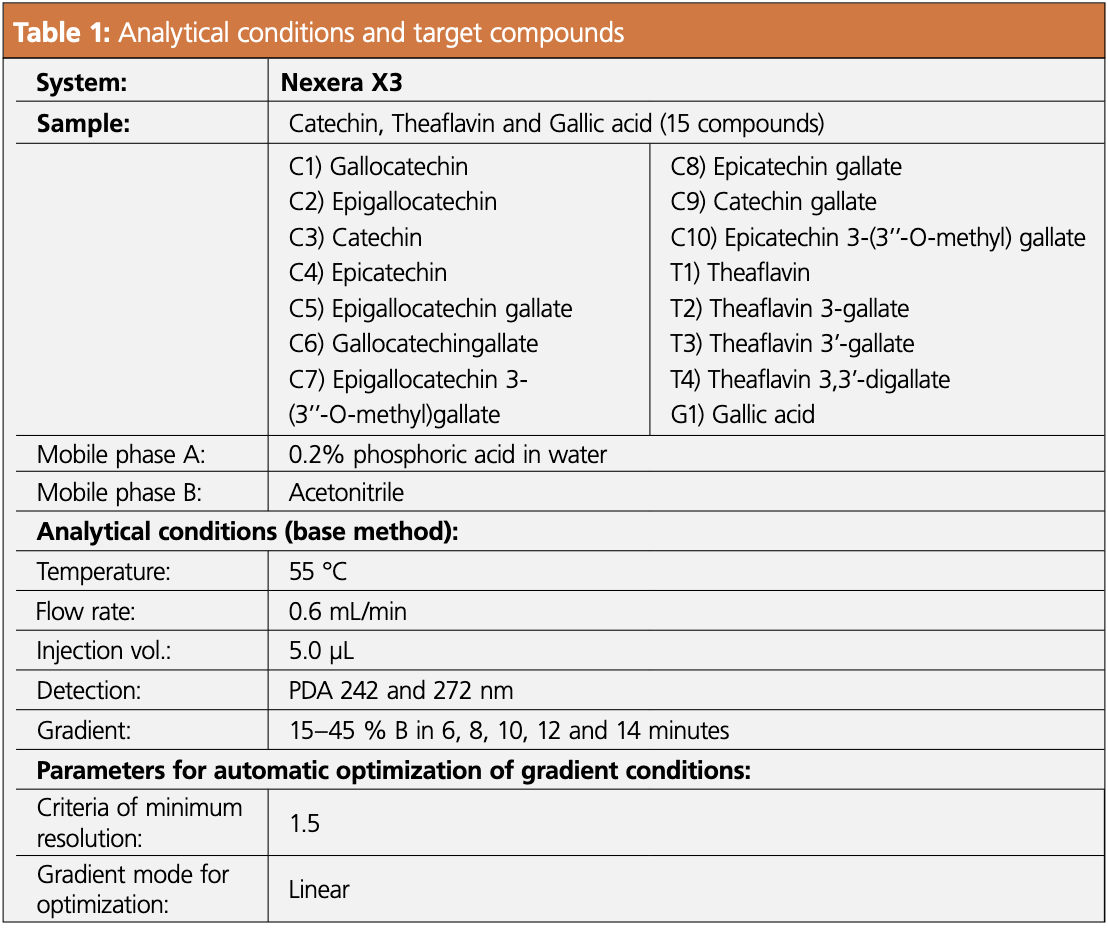

The analytical conditions and target compounds are detailed in Table 1. The LC system used was a Nexera X3 (Shimadzu). Ten catechins, including epigallocatechin gallate, epigallocatechin, epicatechin gallate and epicatechin, which are predominantly found in tea leaves, along with four theaflavins and gallic acid (a total of 15 compounds), were subjected to LC analysis. Initially, the gradient conditions for a mixed standard solution (with ascorbic acid and EDTA-2Na added as antioxidants at concentrations of 1.76 g/L and 1.00 g/L, respectively) were automatically optimized using a novel method development software (LabSolutions MD, Shimadzu, Japan). The optimized gradient conditions were then applied to the analysis of four species of non-fermented green tea and two species of fermented black tea. Figure 1 depicts the detailed pretreatment procedure.

Automated Gradient Optimization

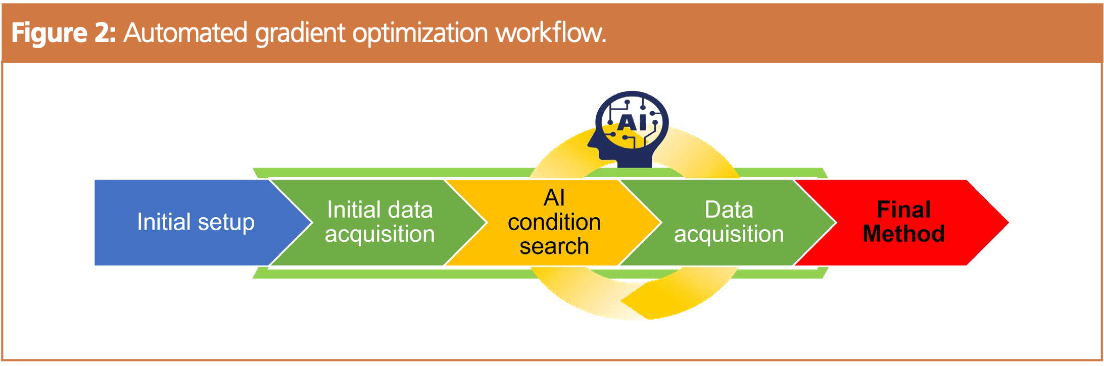

Figure 2 illustrates the workflow for the automated optimization of gradient conditions. This software uses an AI algorithm that automatically searches for gradient conditions meeting resolution criteria by alternately repeating “improvement of gradient conditions by AI (condition search)” and “analysis under improved conditions (correction analysis).”

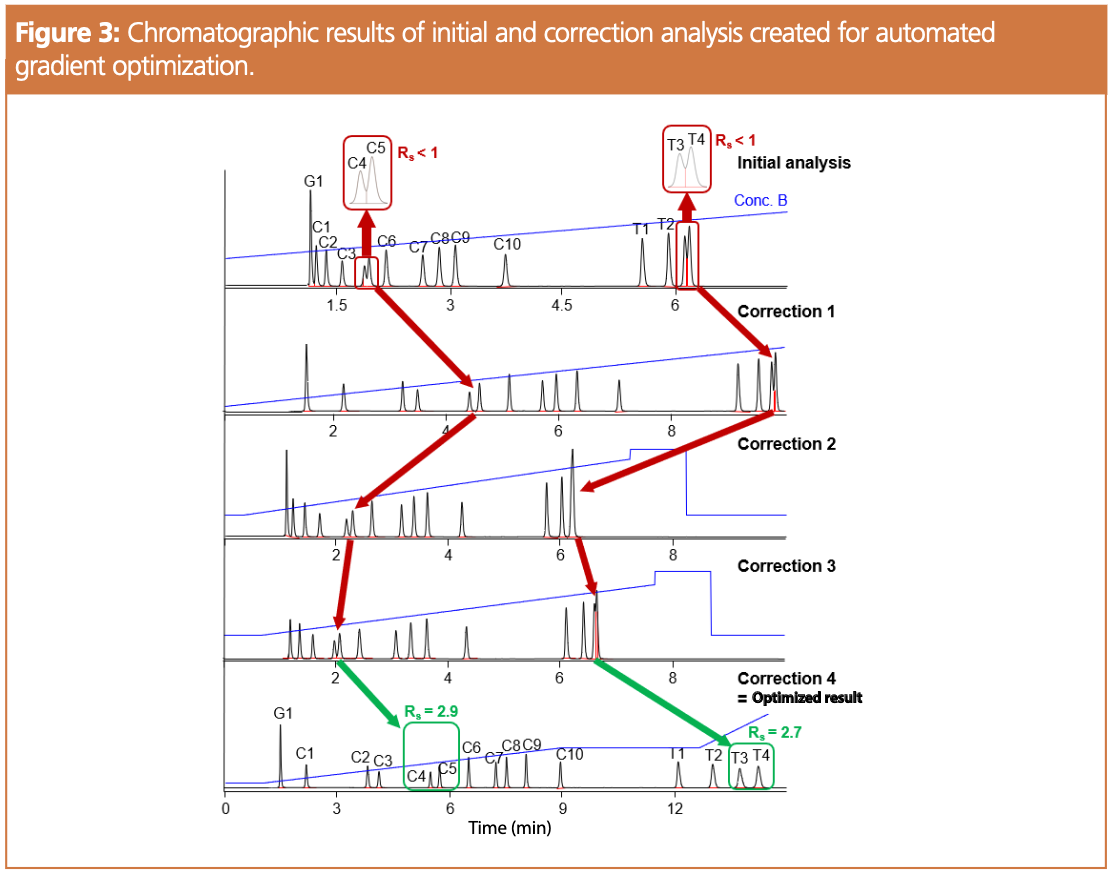

For a mixture of catechins, theaflavins, and gallic acid (a total of fifteen compounds), the gradient conditions were automatically optimized to achieve a minimum resolution of 1.5 for all components as shown in Figure 3.

The initial analysis resulted in insufficient resolution between peaks C4/C5 and T3/T4, as shown in the red box at the top of Figure 3. To address this, AI algorithms were used to perform repeated correction analyses, leading to precise adjustments in gradient conditions. Consequently, an optimal gradient condition meeting the minimum resolution criterion of 1.5 was identified, demonstrated in the green box at the bottom of Figure 3. Notably, this resulted in the successful separation of peaks T3 and T4 through the application of an isocratic elution after 9 min. This illustrates the AI algorithm’s potential to optimize chromatographic conditions, and enhance the accuracy and reliability of complex mixture separations in analytical chemistry.

Application for Tea Leaves

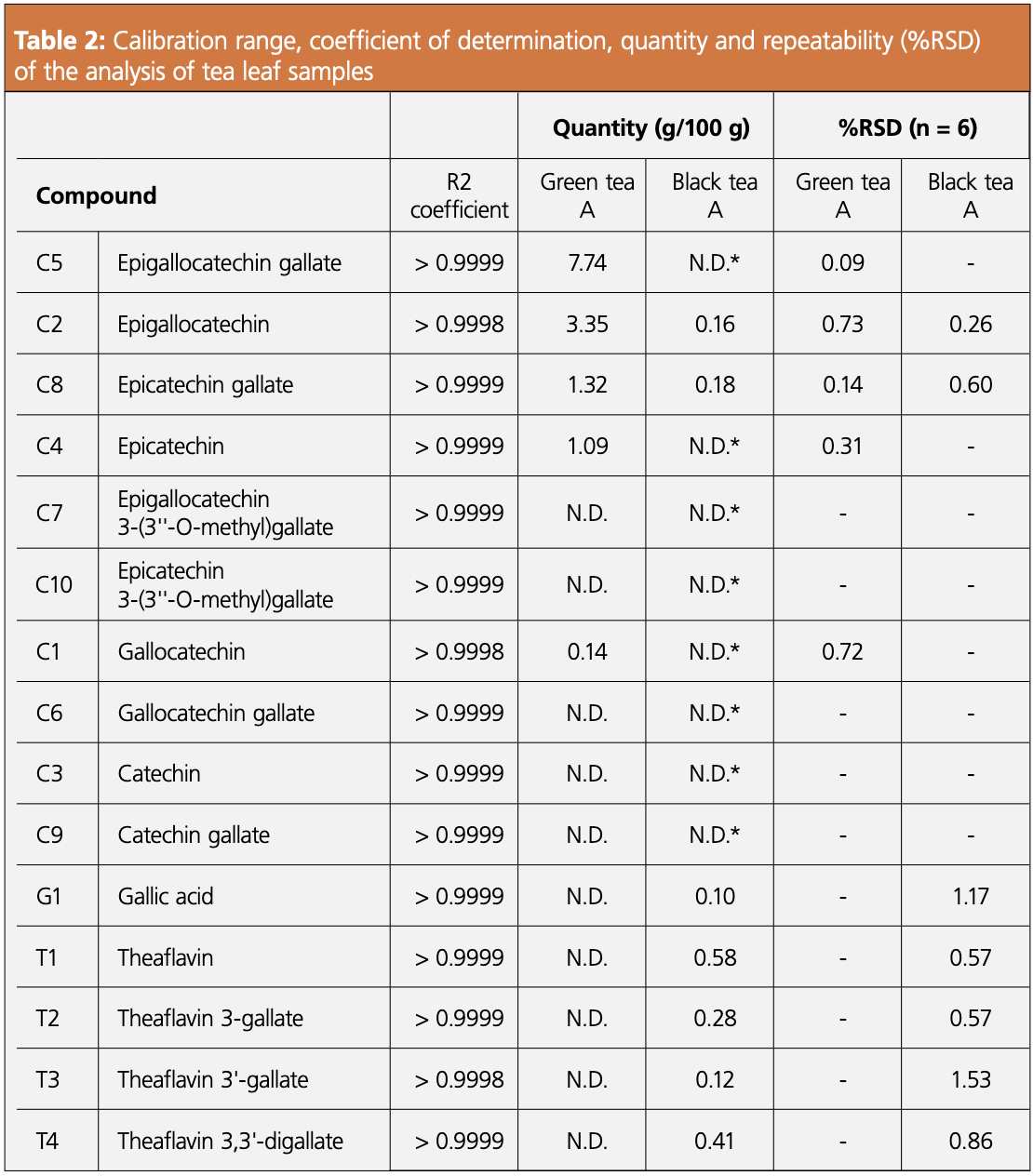

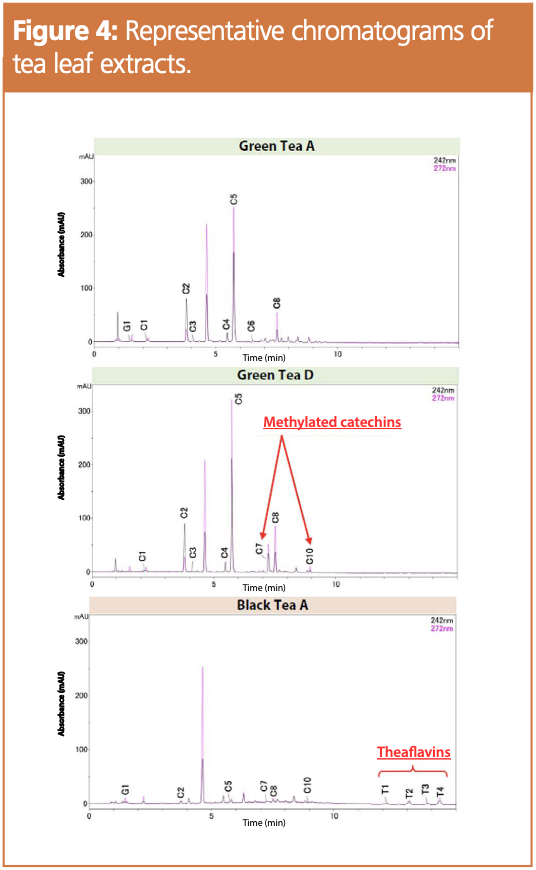

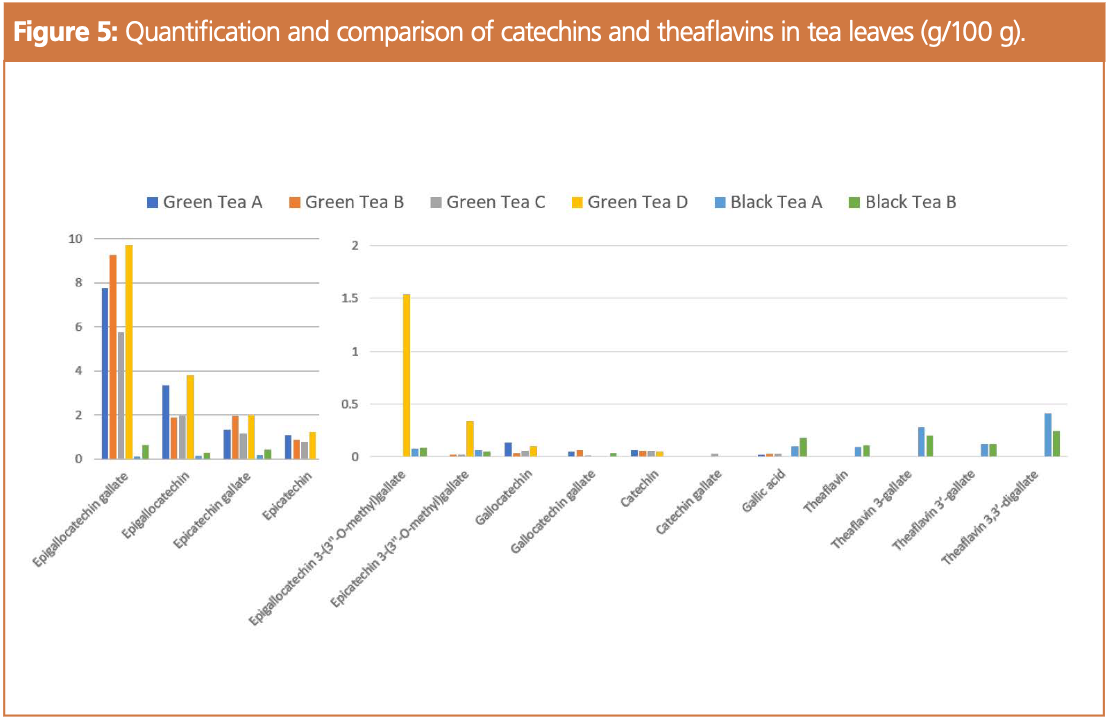

The optimized method was applied to the quantitative analysis of extracts from six different species of tea leaves. Chromatograms of representative tea leaf extracts are shown in Figure 4, while Table 2 lists the coefficients of determination in the calibration range of 1–100 mg/L, quantities (for green tea A and black tea A) and repeatability (for green tea A and black tea A) of the analysis of the targeted compounds. Figure 5 shows a graph comparing the quantities of the 15 analytes of interest in six different tea samples. Green teas A to D were found to contain higher levels of catechins than black teas, including the four major catechins. Epigallocatechin gallate, which is renowned for its potential to inhibit elevated blood glucose, was the most abundant in all four green teas. In green tea D, two methylated catechins, known for their antiallergic properties and ability to reduce hay fever, were also detected. Conversely, four types of theaflavins were identified in black teas A and B. Despite both green tea D and black tea A being “Benifuki” species, the comparison suggests that catechins were converted to theaflavins during the fermentation process. Additionally, the R2 and %RSD values indicate good linearity, repeatability and reliability of the measurements across the analyses.

Conclusion

In our study, we utilized a model sample containing a mixture of fifteen standard solutions, including catechins, theaflavins and gallic acid, which are all known functional components. By employing software with an AI algorithm the gradient conditions to meet our criteria were automatically optimized to achieve a minimum resolution of 1.5. This automation not only reduced labor significantly but also enhanced the efficiency of the analyses. The optimized method was then applied to different tea leaf samples to compare the quantities of these functional components among various tea species. This innovative approach is anticipated to advance scientific discussions and research on catechins and theaflavins. offering a robust tool for future studies.

Reference

(1) Shinichi Fujisaki, Automatic Optimization of Gradient Conditions by AI Algorithm, Shimadzu Application Note 01-00664-EN, February 2024.

About the Authors

Uwe Oppermann is the manager of the European food market segment in the headquarters of Shimadzu Europa GmbH in Duisberg.

Gesa Schad is the Product Manager for HPLC and SFC in the analytical business unit of Shimadzu Europa GmbH in Duisburg, Germany.

Shinichi Fujisaki, M.Eng is a member of the Development Division of Shimadzu Corporation in Kyoto, Japan. Currently he works on applications using LabSolutions MD, a software aimed at automating and streamlining method development workflows.

Silvia Radenkovic on Building Connections in the Scientific Community

April 11th 2025In the second part of our conversation with Silvia Radenkovic, she shares insights into her involvement in scientific organizations and offers advice for young scientists looking to engage more in scientific organizations.

Analytical Challenges in Measuring Migration from Food Contact Materials

November 2nd 2015Food contact materials contain low molecular weight additives and processing aids which can migrate into foods leading to trace levels of contamination. Food safety is ensured through regulations, comprising compositional controls and migration limits, which present a significant analytical challenge to the food industry to ensure compliance and demonstrate due diligence. Of the various analytical approaches, LC-MS/MS has proved to be an essential tool in monitoring migration of target compounds into foods, and more sophisticated approaches such as LC-high resolution MS (Orbitrap) are being increasingly used for untargeted analysis to monitor non-intentionally added substances. This podcast will provide an overview to this area, illustrated with various applications showing current approaches being employed.

Regulatory Deadlines and Supply Chain Challenges Take Center Stage in Nitrosamine Discussion

April 10th 2025During an LCGC International peer exchange, Aloka Srinivasan, Mayank Bhanti, and Amber Burch discussed the regulatory deadlines and supply chain challenges that come with nitrosamine analysis.

Polysorbate Quantification and Degradation Analysis via LC and Charged Aerosol Detection

April 9th 2025Scientists from ThermoFisher Scientific published a review article in the Journal of Chromatography A that provided an overview of HPLC analysis using charged aerosol detection can help with polysorbate quantification.