LECO Corporation

For over 70 years, industries around the world have trusted LECO Corporation to deliver high-performance analytical instrumentation.

Company Description

For over 70 years, industries around the world have trusted LECO Corporation to deliver high-performance analytical instrumentation. Today that commitment continues with high-speed time-of-flight mass spectrometry (TOF-MS) for liquid and gas chromatography, as well as comprehensive two-dimensional gas chromatography (GC×GC), all featuring our easy-to-use ChromaTOF® operating software.

Chief Chromatographic Techniques Supported

- GC-TOFMS

- GC×GC-FID/ECD

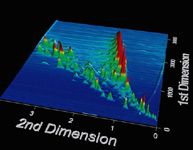

- GC×GC-TOFMS

- LC-TOFMS

Markets Served

LECO Separation Science instruments have been used in a variety of applications, including food/flavor/fragrance, environmental, petrochemical, and metabolomics.

Major Products/Services

LECO's Separation Science instruments are an ideal choice for laboratories resolving complex samples or pioneering higher laboratory throughput. The Pegasus® HT GCMS, Pegasus 4D GC×GC–MS, and TruTOF® HT GCMS give you the ability to obtain and digest large amounts of data in an amount of time that is unrealistic with traditional methods. ChromaTOF software completes this package by giving you the tools you need to manage, process, qualify, quantify, and report data to your liking.

Facilities

LECO's main headquarters is in St. Joseph, Michigan. Customer training, demonstrations, and support are available at our Life Science and Chemical Analysis Center in St. Joseph, as well as facilities in Henderson, Nevada and Fort Myers, Florida. LECO's worldwide presence serves customers in over 24 different countries.

LECO Corporation

3000 Lakeview Avenue

St. Joseph, MI 49085

TELEPHONE

(800) 292-6141

(269) 983-5531

FAX

(269) 982-8977

WEB SITE

NUMBER OF EMPLOYEES

US: 650

ELSEWHERE: 450

YEAR FOUNDED

1936

HPLC 2025 Preview: Fundamentally Speaking (Part 1)

May 13th 2025Michael Lämmerhofer from the Institute of Pharmaceutical Sciences, University of Tübingen, Germany, spoke to JFK Huber Lecture Award winner of 2024 Torgny Fornstedt, professor in analytical chemistry and leader of the Fundamental Separation Science Group, Karlstad University, Sweden, about his pioneering work in high performance liquid chromatography (HPLC) with a focus on fundamentals and industrial applications.

Reversed-Phases for LC Deliberately Doped with Positive Charge: Tips and Tricks for Effective Use

May 13th 2025In this month's edition of LC Troubleshooting, Dwight Stoll and his fellow researchers discuss both the benefits (improved peak shape/loading) and challenges (excessive interaction) associated with charge-doped reversed-phase (RP) columns for both analytical and preparative separations.

Determining Ways to Protect Honeybee Colonies with GC–MS

May 13th 2025A study conducted by the Agriculture Research Centre of Giza, Egypt, and Jilin Agricultural University in China, evaluated the efficacy of stinging nettle extract, nettle smoke, and formic acid in the controlling of Varroa mites, a major threat to honeybee colonies, with a focus on mite infestation reduction, honeybee mortality, and biochemical responses. Gas chromatography–mass spectrometry (GC–MS) was used to identify key bioactive compounds in the stinging nettle extract.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)