Showa Denko - Shodex Rapid SUGAR Series: Fast Fermentation Monitoring and Sourdough Cultures

Living organisms (yeast and bacteria) were not identified as the agents that produced or spoiled common food items until the 19th century. Baking, especially of bread, was among the first industries to be transformed by the emerging scientific understanding of fermentation. The introduction of commercialized yeast in the early 20th century steadily reduced the time needed to bake bread both at home and on the production line, making way for modern packaged breads (1). However, traditional fermentation techniques, including sourdough breads, have resurged in popularity. Typical sourdough cultures are created from yeast and bacteria populations naturally present in the air and on many surfaces, providing sourdough loaves with their characteristic rise and “tangy” flavor by converting fermentable sugars into CO2 and flavor compounds like lactic acid. In this application note, a “homemade” sourdough starter culture was analyzed to determine how key fermentation products changed over the course of 24 h with the new Rapid SUGAR SH1011 8C column.

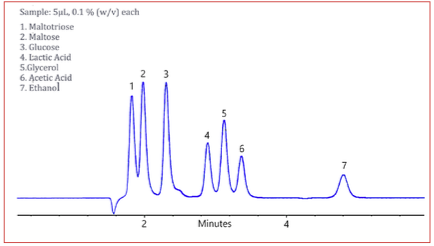

The ShodexTM Rapid SUGAR SH1011 8C column contains a styrene divinylbenzene base material ligand exchange column, and is designed for rapid fermentation monitoring, allowing for the analysis of saccharides, organic acids, and ethanol in less than 5 min. The method uses simple aqueous conditions and RID detection, ideal for large sample workflows and QC environments.

Experimental

Seven common fermentation compounds (maltotriose, maltose, glucose, lactic acid, acetic acid, glycerol, and ethanol) were used as standards. The sourdough starter culture was adapted from King Arthur (2), with the procedure repeated daily for two weeks.

Sample preparation

Approximately 10 g of sample was homogenized with 90 mL of distilled water (for 30 s, with the blender on maximal speed). Five milliliters of 1 mol/L HClO4 solution was added to a 10 mL aliquot of the homogenate. The mixture was centrifuged for 15 min at 4000 g at 15 1C, the supernatant was neutralized (pH 7.0) with 2 mol/L KOH, and the volume was adjusted to 25 mL with distilled water. After 30 min precipitation on ice, the solution was filtered on 0.45 mm cellulose filter, adapted from reference 3. Samples were taken starting on Day 15 at three time points:

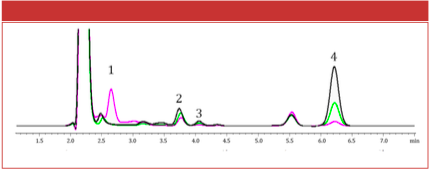

Sample 1: Immediately after mixing in flour and water, labelled time 0

Sample 2: 12 h after time 0

Sample 3: Day 16, approximately 24 after time 0

Shodex SUGAR SH1011 8C (8.0 mm I.D. × 100 mm, 6 μm) was used with a Shodex RI-501 detector. The eluent conditions were: 1 mM H2SO4 aq. The column was kept at 75 oC, and the flow rate was 1.0 mL/min. The chromatography was performed on a Shimadzu Prominence I series LC 2030 instrument.

Figure 1: RI chromatogram of fermentation standards, 0.1% w/v each, 5 uL injection.

Figure 2: Sourdough timepoints: Pink is time 0, green is 12 h, black is 24 h. Peak 1: glucose and sample matrix. Peak 2: lactic acid. Peak 3: glycerol. Peak 4: ethanol.

Results and Discussion

This simple method using 1 mM sulfuric acid as the eluent demonstrated a successful simulated analysis of fermentation byproducts in less than 5 min, including the column equilibration time.

For the analysis of the sourdough starter culture, a guard column was used: ShodexTM SUGAR SH-G (6.0 × 50 mm id, 10 μm) (Figure 2). A method for rapid fermentation monitoring was developed using the Shodex SUGAR SH1011 8C column. Fermentation sample measurement was completed in 6 min. The column showed good robustness when used with complex sample matrices like sourdough cultures. The results show that the SH1011 8C column can be used to monitor fermentation products like organic acids and ethanol.

References

(1) J. Marx, J.H. Litchfield, A Revolution in Biotechnology (Cambridge University Press, 1989).

(2) The King Arthur Flour Baker’s Companion: The All-Purpose Baking Cookbook (The Countryman Press, 2012)

(3) D. Lefebvre, V. Gabriel, Y. Vayssier, and C. Fontagné-Faucher, Food Sci. Tech 35 407–414 (2002).

ShodexTM/Showa Denko America, Inc.

420 Lexington Avenue Suite 2335A, New York, NY 10170

tel. (212) 370-0033, X116, fax: (212) 370-4566

Website: www.shodexhplc.com